Ultra-high performance fiber building material (UHPC), practical experiences and current “green” further developments

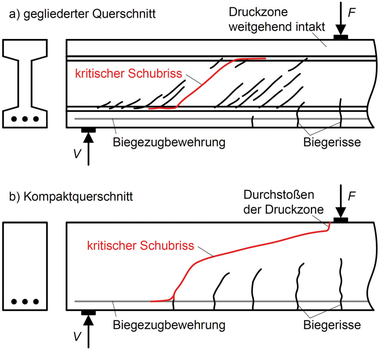

The ultra-high performance fiber building material, a pure mineral concrete matrix in combination with steel fibers, is one of the standardized and common building materials in Switzerland. On the basis of the Swiss standard SIA 2052, more than a dozen of infrastructure projects have been refurbished by Implenia with success in Switzerland since 2018, thus being maintained for the future. In this regard, UHPC represents an efficient solution for preserving existing structures in the field of infrastructure by using this building material for road surfaces including the compensation of gradients and bridge caps, while the material serves as sealing system and protective layer too. Hence, the positive results include material reductions as well as massive savings in time, and an execution of the works all year round. In comparison with normal concrete, UHPC is distinguished by high compressive strengths of 150 up to 200 N/mm², high flexural tensile strengths of over 30 N/mm², an increased resistance to impact and shock as well as an improved crack behavior (inhibition of the formation and expansion of cracks). Because of these characteristics, the building material, among others, can be used for traffic areas, industrial flooring, bridge pavements, reinforcement measures and precast concrete elements. Above all, the possibility to reduce the slab thickness at a given loading in comparison to a conventional steel-reinforced concrete slab or the use of thin-walled structural components, where the accommodation and the corrosion protection of conventional reinforcement would be a problem, result in higher sustainability.

Pilot projects are on the verge of realization nationwide. At the same time, this building material is constantly being further developed with the aim of increasing the service life (durability) and performance of the concrete. This makes an active contribution to the circular economy by using recycled aggregates. Moreover, resources are conserved by using concretes with reduced cement contents, the so-called “green” concretes, and alternative reinforcement materials instead of steel fibers.