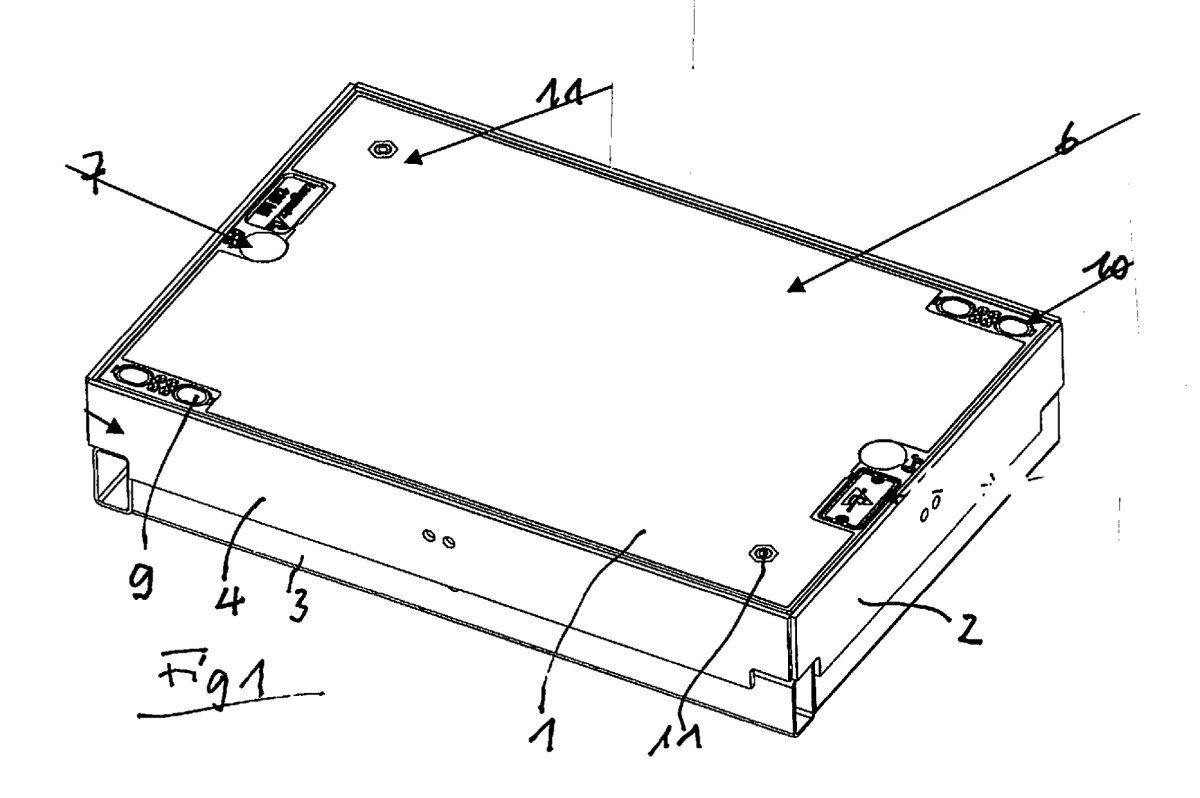

Rapid rehabilitation of manhole covers using fast-setting repair mortar

31.07.2025

Figure: Korodur

In March 2025, several manhole covers were rehabilitated in a residential area of Berlin-Friedrichshain. The works were carried out using a repair mortar designed to minimise both construction time and traffic disruption. The contractor, M. R. Bauservice Berlin Brandenburg GmbH, used Mortar Mix by Korodur for the first time in this context.

Figure: Korodur

In March 2025, several manhole covers were rehabilitated in a residential area of Berlin-Friedrichshain. The works were carried out using a repair mortar designed to minimise both construction time and traffic disruption. The contractor, M. R. Bauservice Berlin Brandenburg GmbH, used Mortar Mix by Korodur for the first time in this context.

Time-sensitive maintenance in an urban environment

The aim was to replace old, rattling manhole covers with new, sealed and lockable models. As the work was carried out in public traffic areas, a fast construction process was essential. Mortar Mix offered clear advantages: the pre-blended mortar is applied in a damp-earth consistency and reaches an early compressive strength of 17 N/mm² just 60 to 90 minutes after application.

Michael Richter, Managing Director of M. R. Bauservice, sees future potential for the product: while its rapid setting time requires precision when mixing, it significantly increases on-site efficiency. Each manhole cover—approximately 650 kilograms in weight—required around 200 kilograms of mortar. No formwork was needed, as the mortar was shaped directly using masonry trowels.

On-site support from the manufacturer

The project was supported by Thomas Gerhard, field representative at Korodur. He provided hands-on guidance to the site crew and gave advice on best practice for applying the mortar, including how to extend the working time by adding a setting retarder when needed.

One key benefit: just two hours after placing the manhole cover, the road surface—such as asphalt—can be reinstated. This enables a continuous construction process with significantly reduced traffic disruption.

Product trial via building materials supplier

Prior to this project, Mortar Mix had already been demonstrated to the contractor at the Mahlsdorf branch of Atala GmbH, a building materials supplier in Berlin. M. R. Bauservice had approached Atala in search of alternatives to their previous repair materials. André Müller, Atala’s field representative, proposed a trial application. The results were convincing, and Mortar Mix has since been added to Atala’s warehouse stock for immediate availability.

Additional areas of application

In addition to manhole rehabilitation, Mortar Mix is also suitable for installing heavy-duty drainage channels—especially in areas subject to high wheel loads, such as logistics ramps or supermarket delivery zones. Further applications include general concrete repair, levelling layers, stucco and plaster patching, formwork repairs, and road maintenance.

CONTACT

Korodur

Westphal Hartbeton

GmbH & Co. KG

Wernher-von-Braun-Str. 4

92224 Amberg/Germany

+49 9621 47 590