VHV Anlagenbau replaces dumpers with advanced steep conveyor technology

24.07.2025

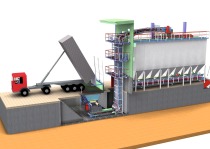

Figure: VHV Anlagenbau

VHV Anlagenbau GmbH has developed a new technical solution for material transport: a booster station extends the existing deck belt conveyor system, enabling conventional means of transport such as dumpers to be replaced in certain areas of application. Industry experts and representatives recently expressed interest in the innovation.

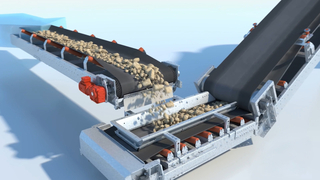

Figure: VHV Anlagenbau

VHV Anlagenbau GmbH has developed a new technical solution for material transport: a booster station extends the existing deck belt conveyor system, enabling conventional means of transport such as dumpers to be replaced in certain areas of application. Industry experts and representatives recently expressed interest in the innovation.

The further development is based on the globally proven deck belt conveyor system, which is currently used in around 1,000 plants. The patented booster station makes it possible for the first time to implement intermediate drives without material transfers. This eliminates the previous limitation on conveyor length, allowing continuous material transport over greater height differences – for example, in deep quarries, gravel and crushed stone plants, and mining operations.

Alternative to dumpers with operational advantages

Transporting material by dumper often involves a great deal of organizational and technical effort. In quarries with terraced terrain, weather-related restrictions and complex driving cycles can lead to delays. The optimized deck belt conveyor from VHV offers a potential alternative with the following advantages:

- Reduction in transport and operating costs

- Lower personnel requirements and reduced space consumption

- Use of narrow, steep single-track routes

- Reliable operation even in adverse weather conditions

- Reduced noise, dust, and CO₂ emissions

- Electric drive, compatible with renewable energy sources

- Modular design – adaptable to the depth of the mining site

“With the new steep conveyor technology, we are responding to the current requirements in the raw materials sector,” explains Patrick Börgel, Managing Director of VHV Anlagenbau GmbH. “The focus is on technical reliability, economic efficiency, and environmental compatibility.”

Initial projects following Bauma 2025 presentation

The system was presented at Bauma 2025, among other venues, where it met with lively interest. The technology is now being tested and further developed in initial projects.

CONTACT

VHV Anlagenbau GmbH

Dornierstr. 9

48477 Hörstel/Germany

+49 5459 9338-0