Use of carbon short fibers in ultra-high performance concrete (C-UHPFRC) – Optimisation approaches

C-UHPFRC is an innovative material that is characterized by its high strength and the formation of very fine multi-cracks. Non-metallic carbon fibers combined with a ultrahigh-strength concrete matrix offer benefits such as improved surface properties and non-corrosiveness. They present a more sustainable alternative to conventional steel fibers.

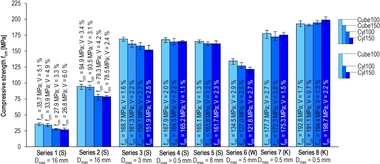

In collaboration with the industrial partners Implenia, KIBAG and newcycle, Munich University of Applied Sciences has performed extensive laboratory testing on rheological and mechanical properties. A parameter study was conducted in order to gain a comprehensive understanding of C-UHPFRC as a building material. The compositions investigated were compared in a detailed evaluation to obtain an optimized mixing design.

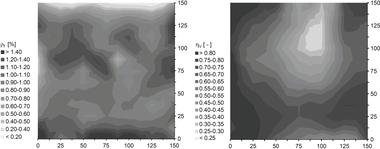

The study focused on the flexural behavior of C-UHPFRC. Additional tests were performed on compressive strength, modulus of elasticity, and rheology. By adjusting the individual parameters, it was possible to develop material compositions that convince in rheological as well as mechanical terms.

Structural components with over-critical reinforcement exhibit the formation of multiple cracks what is important for high durability. The inverse analysis according to SIA2052 did not show any strain hardening behavior related to axial tension. However, it is recommended to verify the applicability of inverse analysis to C-UHFB without further adjustments.

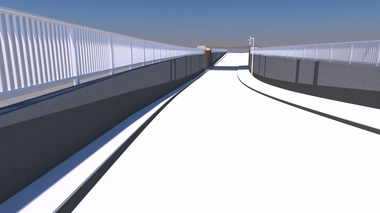

Regarding the mechanical properties, C-UHPFRC does not fully achieve the high strengths of steel-fiber reinforced UHFRPC. However, the results of the parameter study indicate further potential for optimisation. The tests have resulted in a large number of potential applications. C-UHPFRC offers high durability

while complying with visual and safety

requirements, for example with regard

to traffic surfaces. Other potential areas

of application include slender load-bearing components with high aesthetic standards.