Laso uses Flexmax for transporting concrete beams

When long and self-supporting loads are involved, transport solutions are heavily dependent on the road profile. Self-steering vehicles are used where multiple pivot points are required, such as on winding roads. Operations carried out by the heavy-goods specialist Laso Transport illustrate how innovative technologies and precise planning can work together seamlessly.

The guiding principle of maintaining as much freedom as possible in handling complex loads significantly influences vehicle development. This is exactly where the Flexmax trailer combinations, thanks to the turntable technology, show their worth. “They enable extraordinary maneuverability, which is invaluable especially on difficult roads or in confined spaces,” says Beatriz Santos, Marketing Manager at Laso Transport.

Self-supporting goods through tight curves

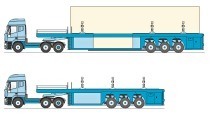

In essence, the functionality is simple: owing to the self-supporting structure of such goods, the dolly in the rear autonomously follows the front running gear, including the tractor, without limit to lengths. “Our general impression of the air-suspended 3+5-axle vehicles with 19.5-inch tires is absolutely positive,” says Beatriz Santos, who gives an insight into how Flexmax proves itself in Portugal.

This time it’s about the transport of concrete beams for the construction of a logistics park. Unit lengths of 25 meters each, and weights of 70 and 56 tons, placed special demands on the logistics. The route leads from Pinhal Novo to Santarém, north-east of Lisbon. The route profile makes the planners really think hard. “One of the greatest challenges here is to ensure safe maneuverability and stability of these long beams – especially in the tight curves and on narrow roads,” as those responsible at Laso Transport report. “In addition, precise planning and coordination are needed to minimize disturbances and ensure on-time arrival of materials.”

Sustainable and reliable solution

Flexmax has long established itself as one of the trump cards in the vehicle fleet of Laso Transport. The vehicles – the dolly in front is self-tracking, and the rear dolly is hydraulically force-steered. “Self-steerers greatly reduce wear, both in equipment and on the road infrastructure: an aspect decisive for long-term reliability,” explains Beatriz Santos. Aside from this duo as 3+5 model, Laso Transport also uses the 2+4 Flexmax variety with wind wing adapter. The Flexmax technology will also have a positive effect on corporate development. “With this technology, we can flexibly adapt to the various load sizes and weights. This will increase our efficiency and at the same time enhance security, precision and customer satisfaction.”

CONTACT

Faymonville Distribution

Duarrefstrooss, 19

9990 Weiswampach/Luxembourg

+352 26 90 04 421