Emission-free loading of hollow core slabs with road-rail vehicle

The Austrian construction group Habau Group invested eleven million euros in the expansion of its hollow core slab production at the Perg plant site. This will increase capacity by almost 30 % per year. As in the entire preliminary planning of the new plant technology, the company is also relying on sustainable technology for the loading and exit processes, such as an emission-free road-rail vehicle.

In just 11 months, a new highly automated hollow core slab production line was built at the Perg plant site in Upper Austria. With the expansion of capacities from currently 70-80,000 m2 to approx. 100,000 m2 of hollow core slabs annually, Habau Hoch- und Tiefbaugesellschaft m.b.H. is thereby meeting the large number of its own construction projects. „The new plant technology will secure our competitiveness on the precast market in the long term,“ said Manfred Karl, Business Unit Manager of Habau‘s precast plant, at the grand opening ceremony on June 14, 2023.

Sustainability as an important factor

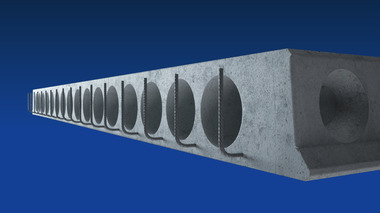

„The precast slabs used here, which are primarily used in industrial and commercial construction, represent a manufacturing process that is significantly lower in CO2 emissions due to less concrete being used as a result of the optimized cross-sections,“ explains Christoph Haider, Group Manager Precast Planning at Habau. Sustainability and flexible, emission-free processes were also relied on when moving the prefabricated hollow core slabs out into the newly created 7,500 m2 outdoor storage area.

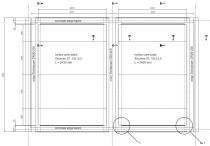

Once pre-produced, the slabs must be made available as quickly as possible for loading onto the next construction sites so that they won’t block further production-side processes. „A particular challenge here was that the rail-bound, 200 m long exit route to the loading points contains a curve with a 20 m inner radius,“ describes Markus Schenk, Project Manager Sales at Vollert.

Road-rail vehicle for extending the hollow core slabs for loading

Vollert engineers therefore opted for a VLEX 20 road-rail robot. „This solution offers an interesting alternative to the conventional extending transport vehicles,“ says Schenk. The maneuverable shunting solution for rail and road is not only capable of moving heavyweights, but it is also possible to take on other transport tasks in operation away from the rail track. In order to realize cornering with the ceiling stacks, which are up to 20 m long and 2.4 m wide, a purely rail-bound solution with trailing cars was developed. „A total of four trailing cars are flexibly connected via coupling rods to transport slab stacks with a dead weight of up to 60 t,“ explains Christian Langner, project manager at Vollert. The trailing car travels with four running wheels each and is equipped with a bogie on which the slab stacks are placed for cornering. Once in the loading area, three overhead cranes take the slab stacks directly from the trailing cars for provision for further construction sites.

The rail-road robot is operated via a joystick wireless remote control. The technology is battery-powered and therefore emission-free. The VLEX 20 moves the ceiling stacks with ease: With a tensile load of over 20 kN and a tare weight of 5 t, the rail-road robot is suitable for heavyweight transport goods weighing up to 300 t. Its sophisticated vehicle geometry with articulated steering and four individually controlled wheel hub motors ensure that it makes the switch from track to road particularly maneuverable and economical.

From the pilot stage to real operation

Hydraulically lowering track guide rollers for rail travel and an oscillating axle guarantee continuous ground and rail contact

for all four wheels, regardless of the surface.

„The first pilot operation is almost complete,“ explains Manfred Reiter, Habau‘s project manager. „We are now starting real operation. The first experiences with the VLEX in the loading processes are very positive.“ Not only with the plant expansion, the Habau Group is thus sending a strong signal for sustainable growth and a CO2-reduced construction method already in pre-production.

CONTACT

Vollert Anlagenbau GmbH

Stadtseestr. 12

74189 Weinsberg/Germany

+49 7134 52-0