Lammers Beton invests in automation and software integration

Lammers Beton has emerged as a leading company in precast concrete production through automating its machinery and using software solutions. Founded in 1987, the business currently operates three production sites in Weert, the Netherlands, and employs more than 235 people.

Lammers Beton specializes in complex, architecturally sophisticated precast elements such as façades, balconies, galleries, and structural components. Its customers primarily include construction contractors that rely on the company’s expertise in high-quality precast products.

Innovative reinforcement technology

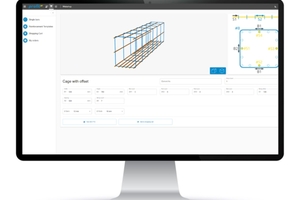

A key step in automation at Lammers Beton was the acquisition and integration of a Progress Group M-System PowerMesh mesh welding plant equipped with a beam bending system. Operating such high-performance equipment has increased production capacity dramatically while streamlining operations considerably by shortening production cycles and reducing the amount of required storage space.

Investing in software solutions

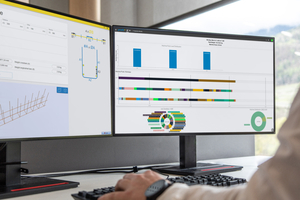

Another pivotal step was to integrate the profit software suite from Progress Group. The software has

primarily been utilized for the integrated rebar shop and includes capabilities like production monitoring and workload profiling, significantly enhancing the planning and production process. Initially regarded with some skepticism, the software soon proved to be exceedingly helpful for generating accurate mesh data and enhancing production efficiency. Hein Moors, 3D process engineer at Lammers Beton, elaborates on the initial skepticism and lessons learned: “At the beginning, I thought we would not use the software much. However, its full potential became evident once we started using it extensively to optimize our processes.”

Efficiency gains

At Lammers Beton, investing in automation and software has led to notable improvements in efficiency. Producing on-demand meshes and bent products enabled the company to reduce storage needs and minimize waste while improving the overall quality of its precast elements. Moors adds: “We are now able to produce mesh exactly when we need it, which enables us to enhance efficiency on the factory floor while also elevating product quality.”

Positive experience

Collaborating with Progress Group proved to be a positive experience for Lammers Beton. Moors praises the service team’s responsiveness and expertise: “We were pleasantly surprised by the team’s quick answers and expertise. It is extremely important to work with partners who genuinely understand what reinforcement and machine operations entail.”

Implementing BIMpro

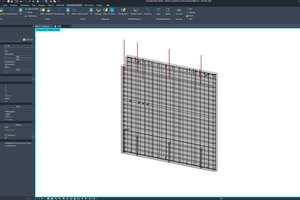

In its pursuit of continuous improvement, Lammers Beton also integrated BIMpro, a software solution designed to further enhance 3D reinforcement modeling in Autodesk Revit. Previously, the company had relied on conventional 2D drawings, which sometimes failed to capture the full complexity of state-of-the-art construction specifications. BIMpro provides a smart, efficient alternative that enables engineers to design, visualize and plan reinforcement to an unprecedented accuracy and degree of detail.

Moors highlights the software’s potential: “We firmly believe that BIMpro will help us increase design accuracy and efficiency, which will make it possible for us to go beyond basic modeling and integrate reinforcement details directly into our Revit designs to better anticipate clashes and improve cage producibility.”

Conclusion

Lammers Beton’s strategic investment in machine automation and software solutions underscores the potential of new technologies for industrial processes. The business has enhanced its efficiency and serves as a prime example of how to innovate in precast production. This experience is relevant for other companies in the industry considering steps toward automation and digitalization. Investing in innovative technologies enables Lammers Beton to continue to deliver top-class products while solidifying its leading market position. Moors concludes: “We didn’t just buy a machine; instead, we embarked on a partnership to ensure our continued success.”

CONTACT

Lammers Beton B.V.

Oude graaf 10

6002 Weert/Netherlands

+31 495 547 427

Progress Maschinen &

Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+ 39 0472 979100

Progress Software

Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159