Innovation: Spread 4.0 – Fresh concrete testing via smartphone

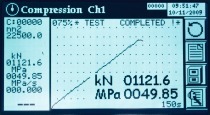

The quality of fresh concrete is crucial for the subsequent properties of the building components. Reliable testing of the required fresh concrete parameters is therefore essential – both on the construction site and in the ready-mixed concrete and precast plant. Today, however, these tests are largely based on manual procedures: consistency is determined using the slump test in accordance with DIN EN 12350-5, while other properties such as segregation tendency, maximum grain size or slime separation are predominantly assessed by subjective visual inspection. Despite the established robustness of the method, measurement, evaluation and documentation are highly experience-dependent, time-consuming and completely analogue. This leads to variability, media breaks and limited traceability – at the same time as there is a growing need for objective, reproducible and digitally integrable testing processes due to increasing quality requirements and the growing shortage of skilled workers.

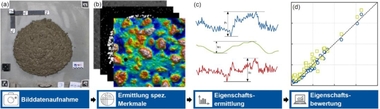

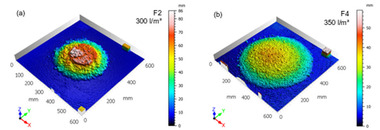

The „Spread 4.0“ fundamentally changes the previously analogue and subjective testing of fresh concrete. With the help of artificial intelligence (AI) and computer vision, a single photo of the spread fresh concrete, taken e.g. with a smartphone or tablet, is sufficient, and the AI developed by Conqrete 4.0 specifically for fresh concrete evaluation and unique worldwide immediately provides:

Spreadability and consistency class,

Maximum grain size and a classification of the grading curve,

Evaluation of segregation tendency and stability.

The Conqrete API provides a plug-and-play interface that can be seamlessly integrated into existing software and external QA systems. Building material testers can continue to work with their familiar tools – only faster, more accurately and completely digitally.

The Conqrete app also provides a digital assistant as a standalone mobile app solution, which building material testers can use to perform automatic fresh concrete testing anywhere, with all tests digitally documented and stored centrally.

The Spread 4.0 is ideal for a wide range of users – from concrete manufacturers, testing laboratories and precast plants to construction companies. For the construction site, the process represents a significant advance: testers receive objective results in a matter of seconds, without manual measurement and without analogue documentation. All data is immediately available in digital form, structured and without media discontinuity, and can be integrated directly into existing quality assurance and project systems as well as test reports.

Ready-mix concrete plants benefit from a standardised and digital tool for in-house production control with high data quality, enabling well-founded feedback loops for optimising recipes, production processes and delivery quality. Complaints can be evaluated more objectively, trends in consistency development become visible and quality management systems receive high-quality input data for continuous improvement. In precast plants, automated image-based testing creates greater process reliability and reproducibility. Digital documentation makes concrete quality traceable and enables fresh concrete data to be directly linked to production and component information. Reject rates can be reduced and production processes better controlled.