Slump Flow 4.0 - Digital quality control

As a result of the imperative need to reduce the environmental impact

of concrete production, increasingly complex formulations are used in

practical application with, in some cases, nine to ten different source mater-

ials. This turns troubleshooting into an extremely complex matter

in the event of any variations. At the same time, there are only very

simple empirical testing procedures available for tesing the concrete

properties at the plant or on the construction-site, and (corrective)

measures are based almost exclusively on subjective visual inspection

and the experience-based knowledge of the parties involved. The

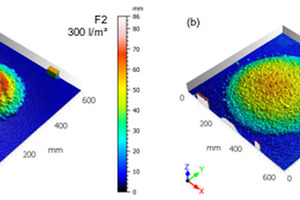

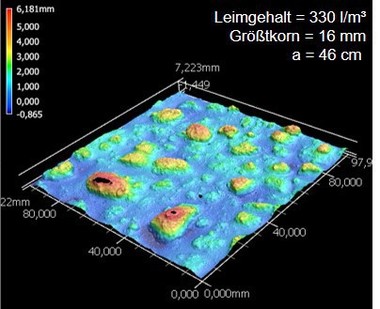

standard testing procedure used is the flow table test. In this process,

the flow behavior of the concrete is inferred from the diameter of

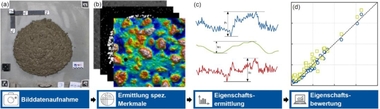

the spread-out fresh concrete. The aim of the work presented in this

paper was to translate the extensive experience-based knowledge of experienced engineneers into digital methods in order to carry out a comprehensive neutral evaluation of the quality characteristics of the fresh concrete. In the project, which was funded by the German Concrete and Construction Engineering Association

(Deutscher Beton- und Bautechnik-Verein E. V.), an image-based

measurement methodology with subsequent evaluation by computer

vision-based methods was developed in order to integrate such digital standards into consistency testing. For this purpose, the spread-out fresh concrete is captured using photogrammetry methods and the image taken is then evaluated by means of

computer vision-based methods. In add-

ition to the diameter, extensive informa-

tion – previously inaccessible to the testing person – on, for example, the concrete composition, variations in the water content, or the stability of the fresh

concrete can be inferred from parameters

such as the surfacepattern. The charac-

teristic values canbe directly incorpora-ted into a (future)digital quality control of concrete or precast production and are a vital keyfor implementing digi-tal selflearning control loops to control

and manage concrete properties. The

authors would like to thank the German

Concrete and Construction Engine-

ering Association for funding the work presented in this paper.