New testing procedures for effective evaluation of

fresh-concrete rheology suitable for use on site

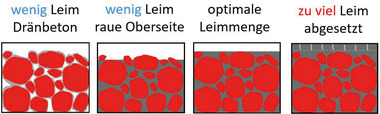

The conventional evaluation of fresh concrete on the basis of flow consistency is frequently not sufficient to ensure proper concrete processing. Subsequent surface finishing may be severely impaired, for example, if the fresh concrete – despite sufficient flow consistency – is excessively sticky or hardens at different times during each concrete pouring operation. If the fresh concrete properties are to be evaluated further, the rheological properties, mainly yield limit and viscosity, need to be determined in rheometers. Although rheometers for concrete do exist, they are too complex for acceptance tests on the construction site.

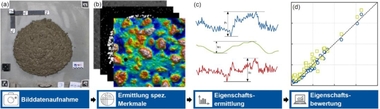

For a more detailed evaluation, standard testing procedures were modified so as to allow a more detailed assessment of the rheological parameters and thus a more specific assessment of the fresh concrete. Particular emphasis was placed on ensuring that these procedures are suitable for use on the construction site. When determining the flow consistency according to DIN EN 12350-5, a homogenized value is determined in the physical sense. The time component, which describes in particular the viscosity, is not sufficiently taken into account. Using an incremental approach, that is, incorporating two intermediate steps, allows this procedure to be used as before, but findings related to stickiness can be derived from the intermediate steps. Measuring the penetration time of a steel ball in concrete previously compacted in a conventional compaction box according to EN 12350-4 permits additional information to be obtained on the time component, that is, on the viscosity of the fresh concrete.

In addition, comparative tests showed the robustness of the fresh concretes based on these two parameters with regard to surface finishing, for example, by means of power troweling.