Improve quality and productivity through automation of concrete testing laboratories

When the building material industry finds itself in a serious crisis, how can a concrete testing laboratory attempt to remain competitive while raising profits? The answer:

Enhancing quality and productivity through automation.

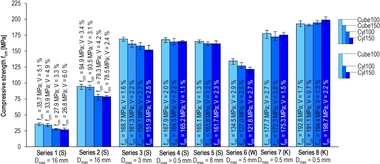

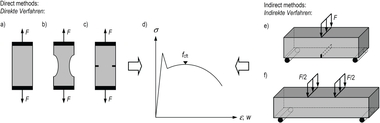

For control purposes concrete is normally required to be tested under uniaxial compression, indirect tension and flexure. In view of the importance of concrete cube, cylinder and core testing within the construction industry compression testing machines have been the subject of more rigorous standardized performance testing. The most recent EN 12390-4 is essentially a performance specification which allows each manufacturer to design a testing machine using his own expertise and ideas provided that complying with geometrical and mechanical requirements for parts.

On the other hand concrete...