Industrial Development Agency JSC invests in Suchedniów, Poland

Important factors affecting the profitability of investments include not only the construction completion time, but also the appropriate selection of solutions and value engineering. How do modern prefabricated production technologies support investors, contractors and designers in this area? ARP Budownictwo comes with the answer.

Dynamic changes in the construction industry bring with them numerous challenges, including increasing construction costs or lack of hands to work, which inhibit activities or increase the costs of investment implementation. However, it is worth remembering that the optimization of human and material resources has great potential. Important factors affecting the profitability of the investment include not only the construction completion time, but also the appropriate selection of solutions and value engineering. How do modern prefabricated production technologies support investors, contractors and designers in this area? ARP Budownictwo comes with the answer.

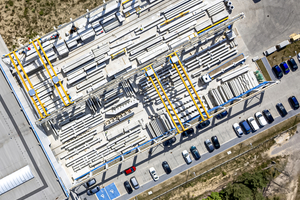

In the era of challenges facing the construction industry, it is worth paying special attention to the difficulties faced by regions threatened by economic exclusion and growing unemployment. The Agency for Industrial Development deals with the activation of such areas. On the site of the former Zakłady Wyrobów Kamionkowe „Marywil“ S.A. in Suchedniów, ARP Budownictwo began work on using the potential of this location. In just 10 months after the first shovel was hammered, the company completed the construction of the plant with complete technological equipment and began the production of prefabricated elements in the newly completed factory, which is ultimately planned to employ more than 100 people. On the premises of the modern plant there are production lines for the production of reinforced concrete and prestressed concrete elements, whose annual production capacity of wall and ceiling slab elements alone is up to 400 thousand square meters.

Why ARP enter prefabricated residential buildings?

Precast guarantees the highest quality and optimization of each stage of the investment. Key advantages of prefabricated residential buildings:

Shorter construction time: The use of ready-made prefabricated elements significantly accelerates the implementation of the investment

Lower investment costs: Thanks to efficient production in the Prefabrication Factory in Suchedniów, it can be offered attractive prices (from 5500 PLN/m²)

Larger usable area: The optimal design translates into more available space compared to traditional construction methods.

Design flexibility: Building buildings with a diverse number of apartments and floors, with the possibility of freely shaping the structure of apartments.

Fast implementation path: The investment process consists of only four steps: contract, adaptation and permits, building permit and implementation.

Quality guarantee: Production in factory conditions ensures precision and the highest quality of each structural element.

High energy efficiency: The prefabricated residential buildings are characterized by low energy consumption – EP < 52 kWh/m²/year for the selected project.

ARP: Prefabricated concrete manufacturer with modern high-performance technological lines

ARP Budownictwo specializes not only in the production of high-quality prefabricated concrete elements for individual customers and construction companies, but it acts also as well as general contractor and investment developer.

In the modern Prefabrication Plant, ARP produces high-quality prefabricated concrete using BIM/CAD design and advanced technologies to ensure the highest quality of our prefabricated reinforced concrete elements. All prefabricated concrete and reinforced concrete products are subject to strict control. The efficient production lines allow to produce up to 250 thousand tons of elements per year. ARP produces the following products, guaranteeing:

Repeatability of dimensions and high accuracy of workmanship.

Reliable durability and structural strength.

A significant qualitative advantage over traditional construction methods.

Single-layer walls: are an effective construction solution, combining durability, aesthetics and quick installation with design flexibility.

Multilayer walls are advanced structures that provide comprehensive insulation and design flexibility, meeting energy efficiency standards.

Prefabricated foundations are solid, easy-to-install, high-strength foundations that speed up construction.

Poles and post-poles as basic vertical elements of load-bearing systems, whose task is to transmit vertical and horizontal loads.

Prefabricated reinforced concrete beams: Durable high-quality elements, flexible in use and speeding up construction.

Prefabricated prestressed beams are advanced components with a large span, allowing the carrying of heavy loads.

Hollow core slabs are advanced structural elements for ceilings and roofs

Balcony slabs as inseparable elements of modern residential, industrial and public buildings

Prefabricated stair and resting platforms are ready-made structural elements that allow for quick and precise construction of stairs.

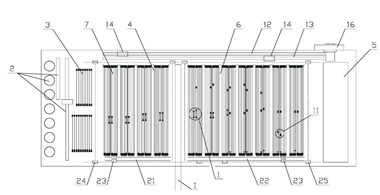

Batch plant of latest generation

When a mix is called, the materials are collected by MCT’s Mobile Aggregate weigh batcher, capacity of 1.5 m3, the ‘mobile scale’ travels under each compartment and receives the correct material volumes, it also allows the materials to be discharged in any order allowing ‘premix’ of material prior to arriving in the mixer. There were several reasons why this was used over a conventional batching / weigh belt arrangement. Primary reasons were greater accuracy of materials being weighed, lower investment costs, elimination of material spillage.

The ‘skip hoist’ then take the materials to the one of the 2 x 2250/1500 planetary mixer, which provide the factory with their concrete. Upon the mixer platform are the normal components such as Cement Weighing, Water distribution, Admix & dust extraction. Each mixer has 2 doors allowing full flexibility and possibility to discharge concrete into both flying bucket lines. Cement is fed from 3 x cement silo of 100T (80m3) and it can be delivered to both mixers.

The concrete is discharged into 2x MCT’s travelling bucket to be supplied to bay 1 or bay 2, with total distance of 350M all of which is controlled via MCT’s own control system, providing the optimum delivery around the entire site in automatic mode. The rollover bucket has a capacity of 3000 liters and can travel at speeds of up to 240M per minute and deliver the concrete directly to the concrete distributor for concrete casting.

The mixers and travelling buckets are washed via MCT’s own designed washing heads and all the washed water and materials are gathered below the plant where they are separated and this water is recycled back into the plant, the waste material can also be recycled. All of the dosing, mixing and concrete distribution is controlled via MCT’s very own Compumat system, which is intuitive.

Ecological solutions and prefabricated elements

The economic advantages of using prefabrication concrete in construction make it a technology that is growing in popularity every year. In the era of projects created in accordance with the assumptions of sustainable construction, it is impossible to ignore the ecological aspects of the use of prefabricated concrete. Thanks to the fact that the elements produced in the Concrete Prefabrication Plant are created under controlled conditions, it is possible to optimize energy and material consumption, as well as reduce waste. Their use on the construction site has a higher ecological potential compared to traditional methods.

What‘s more, thanks to the precision of design based on digital technology, selected prefabricated elements can be optimized, taking full advantage of all conditions allowed by the rules defined by industry standards, construction law and technical conditions. This significantly improves the efficiency and energy efficiency of the facilities being built with their participation. High efficiency and accuracy of forming elements allow the leveling of thermal bridges and have a positive effect on improving the thermal insulation of increasingly appearing architectural solutions. All this translates into better use of resources, ergonomics of implementation and action with economical and sustainable construction in mind.

The versatility and potential of using prefabricated products makes this technology more important. Due to numerous benefits - not only environmental, but also economic or social - it has a good chance of changing the face of the construction industry, positively affecting the environment, the economic potential of the country and the comfort of users of emerging investments

Benefits of using prefabrication technology

The use of prefabricated concrete allows you to significantly reduce the construction time, while maintaining high quality and efficiency of the work carried out. The production of individual elements is carried out under controlled conditions and is supported by computer-aided design (CAD, BIM) integrated with automatic management of production lines. Thanks to this, it increases the efficiency of production, but also the quality of the manufactured elements. The use of specific recipes of concrete mixtures allows to reduce the raw materials used in the production process and reduce the waste produced, and thus – to reduce the associated losses globally.

“Prefabrication is today the answer to many challenges posed by investors and the construction industry “- emphasizes Patrycja Bebas, President of ARP Budownictwo sp. z o. o. “Its indisputable advantage is the reduction in the implementation time of the investment compared to traditional construction, in which the seasonality of the work is in force. Installation of prefabricated elements can take place regardless of weather conditions. The execution of concrete elements in the Prefabrication Plant, in strictly controlled conditions, directly translates into the quality of these elements, but also allows for the reduction of construction work carried out by the traditional method”.

Mr. Falchetti Gabriele, MCT Italy‘s VP Business Development, says: “Prefabricated elements produced by ARP Budownictwo are used in facilities with various utility purposes, and the offer is constantly being developed and adapted to the needs of the changing market. At the Concrete Prefabrication Plant in Suchedniów, it is designed in a BIM/CAD environment and uses technologically advanced tools to support production processes. Manufactured elements are subjected to rigorous quality control, which guarantees the highest quality of products. The plant has optimized and adapted to high efficiency production lines allowing the production of up to 250 thousand tons of concrete elements per year for the needs of cubature construction: industrial, warehouse, public utility and residential”.