Gulf Precast: Redefining efficiency with

machine automation in the UAE

Gulf Precast is revolutionizing the construction industry in the UAE with cutting-edge automation and advanced technology. Through its partnership with Progress Group, the company has enhanced efficiency and elevated quality standards of their mesh production with a brand-new M-System BlueMesh mesh welding plant.

Founded in 1984, Gulf Precast has grown to become one of the UAE’s leading precast concrete manufacturers, playing a pivotal role in shaping the region’s skyline. With landmark projects such as the Dubai Mall and Abu Dhabi Airport under its belt, Gulf Precast has evolved from a single plant to a big market name with multiple facilities. Today, the company operates three precast plants in Abu Dhabi and two facilities in Dubai, including one dedicated to hollow-core slab production.

“Gulf Precast is one of the first precasters in the region,” explains Valentijn Blonk, General Manager of Gulf Precast. “We have expanded our capacity significantly to meet growing market demands and have invested heavily in innovation and automation.”

The role of automation in meeting market demands

The construction sector in the UAE has rebounded strongly after 2020, with a surge in demand for villa construction, schools, and infrastructure. Gulf Precast has risen to the occasion, producing over 1,000 cubic meters of precast concrete daily – enough to build and erect eight villas per day.Automation has been central to this success. By streamlining production and reducing reliance on skilled labor, Gulf Precast ensures it remains competitive in a rapidly evolving market. “We always look for ways to improve productivity, quality, and reliability,” Blonk notes. “Automation has become the future of the industry. The newest machinery we bought from Progress Group enables us to maintain high standards while addressing labor shortages.”

Progress Group’s technology

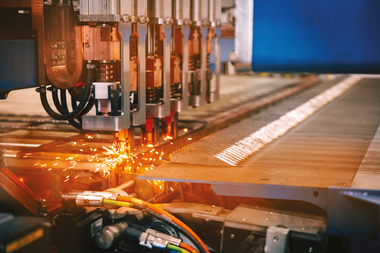

A key driver of Gulf Precast’s success is its partnership with Progress Group. The introduction of an M-System BlueMesh mesh welding plant has revolutionized production processes. This highly automated machine works from the coil and integrates panel openings automatically according to plan. Furthermore, it reduces waste and significantly enhances quality and speed.

“The mesh welding plant from Progress Group has been a game-changer for us,” says Blonk. “It’s not just about reducing labor hours; it’s also about minimizing material waste, increasing accuracy, and delivering a superior product. Even in the UAE, where labor costs are relatively low, the savings are substantial across the board.”

Factory Manager Walid Aoun elaborates on the benefits: “With the automation in place, we can plan and produce much more efficiently. Daily production requirements are communicated directly from our engineering department to the mesh welding plant, which executes them flawlessly.”

Efficiency and flexibility

One of the standout features of the mesh welding plant is its flexibility. The system can customize products to meet specific client requirements. This versatility has proven invaluable for Gulf Precast’s diverse portfolio of projects, ranging from villas to infrastructure.

“When selecting this machine, we prioritized flexibility alongside productivity,” Blonk explains. “Progress Group’s solution met all our criteria, ensuring we can adapt to a wide range of project demands while maintaining high output levels.”

Transforming operations with support and collaboration

Gulf Precast’s longstanding relationship with Progress Group began in 2006 with the implementation of an MSR straightening and cutting machine, which is still operational today. The recent addition of the mesh welding plant represents the culmination of this partnership.

“The installation process was seamless, thanks to Progress Group’s professional team,” says Aoun. “Their service and support have been exceptional, ensuring we get the most out of the technology. Any technical issues were addressed immediately, which made the transition incredibly smooth.”

The training provided by Progress Group was thorough, enabling the staff to fully understand and operate the machinery. This has not only improved productivity but also made the workplace safer and more efficient.

A future built on innovation

The benefits of automation go far beyond mere cost savings. Automation allows the company to deliver consistent quality, improve reliability, and create sustainable processes. Looking ahead, Gulf Precast remains committed to leveraging advanced technology to meet the UAE’s growing construction demand.

CONTACT

Gulf Precast Concrete Company LLC

Head Office

ICAD-1, Musaffah Industrial

Musaffah, Abu Dhabi/UAE

+ 971 2 550 20 44

Progress Maschinen & Automation AG

Julius-Durst-Strasse 100

39042 Brixen/Italy

+39 0472 979100