Pioneering Precast Innovation in Western Canada

Western Canada’s precast industry has gained a new driving force: Matbar Industries, who recently partnered with Progress Group to bring cutting-edge automation into mesh production. With the installation of the M-System BlueMesh mesh welding plant, the young company has positioned itself as a pioneer in rebar mesh production across the region.

A young company with big ambitions

Founded in 2024, Matbar Industries has quickly established itself as a forward-thinking player in the Canadian precast industry. Operating from a 20,000sq/ft precast facility in Alberta, Canada, the company manufactures precast wall panels with custom cut-outs as well as rebar mesh panels for flooring systems.

Matbar Industries delivers reinforcement mesh to precasters and concrete contractors across Western Canada, including British Columbia, Alberta, Saskatchewan and Manitoba. Furthermore, they also serve clients in the Northwestern United States, including Washington, Oregon, Idaho, Montana, North and South Dakota.

Despite being a young enterprise, the company’s plans are ambitious. If current growth continues, Matbar intends to expand production capacity by investing in a second machine – potentially with bending capabilities to diversify its product range.

Choosing automation to stay ahead of the curve

From the beginning, Matbar aimed to differentiate itself in a highly competitive market. The decision to automate production with Progress Group’s M-System BlueMesh mesh welding plant was driven by the desire to become pioneers in Western Canada.

“As it stands currently, no one in Western Canada is producing rebar mesh quite like us,” explains Jordan Gibson, Sales Representative Matbar Industries. “We wanted to be ahead of the curve in the concrete and construction world Western Canada. As well, we aim to deliver quality product to customers that also provides substantial benefits to the end users.”

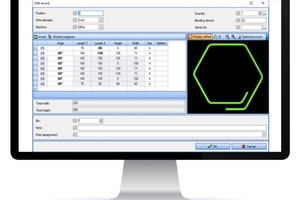

The M-System BlueMesh enables high-speed, fully automated mesh welding with an unmatched level of precision. Its automated welding heads and labelling features allows Matbar to deliver products that are consistent, customizable, and easy to integrate into precast production processes.

“The quality of the product is, what most people, immediately advocate for,” notes Gibson.

Boosting efficiency

Together with the M-System BlueMesh, Matbar also relies on the Profit MES-software. This software allows optimizing the entire planning and production workflow by ensuring that all processes – from order entry to scheduling and resource allocation run smoothly and efficiently. By providing real-time insights into production capacity, material use, and delivery times, Profit enables the team to react quickly to changing requirements while keeping costs low and under control. For Matbar, Profit is a key factor in combining automation with smart production management, ensuring maximum output and reliable delivery performance.

A trusted partnership with Progress Group

For Matbar Industries, the choice of supplier was clear. “We knew we were getting a well-established reputation in the precast world, as well as unmatched machine quality and performance. with Progress Group,” Gibson notes.

From planning to commissioning, the Progress Group team has provided support, guidance, and expertise at every stage. “Our experience has been nothing short of exceptional. From start to finish Progress has been extremely helpful in terms of providing guidance and navigational tools throughout our duration working with them,” Jordan Gibson affirms.

Shaping the future of precast in North America

With the installation of the M-System BlueMesh mesh welding plant, Matbar Industries has positioned itself as a regional innovator in Western Canada’s precast industry. By combining entrepreneurial ambition with Progress Group’s advanced automation technology, the company is setting new standards in mesh production.

CONTACT

Matbar Industries Inc.

848 8 Street

Fort Macleod, Alberta T0L 0Z0/Canada

+1 403 6340286

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979100

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

T +39 0472 979159