Mesh welding becomes leading technology at Abu Dhabi Precast LLC

Abu Dhabi Precast (ADP) established in 2001 is one of the leading precast and pre-stressed concrete companies in manufacturing, delivery, and erection of Precast Products in U.A.E. Since its establishment, ADP has grown from a single factory to multiple facilities in the Mussafah location that are solely owned and operated by Ascorp Holdings.

ADP, with approximately 1.330 high skilled employees, has the capacity to produce 1.200m3 a day of a variety of prefabricated products. ADP’s various products adhere to the strictest international standards and have consequently been approved and utilized in both the public and private sector.

ADP possesses several state-of-the-art machinery and facilities in all of its factories. In the production facility which is located in Abu Dhabi Industrial City-Al Mussafah Industrial area, occupies a total land area of 227.000 m2 with covered production area of 32.000m2. It is equipped with three modern and fully computerized batching plants.

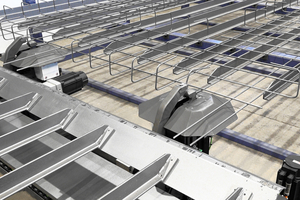

Flexible mesh welding lines with integrated bending modules and unique mesh bending stations - the AMM series

The latest plan of ADP was to invest into a fully automatic mesh welding line for the production of both standard construction mesh as well as engineering mesh, mesh with openings and mesh with bent line and cross wires. After an extensive market research for the most advanced solution, a machine of Eurobend’s AMM Series chosen.

Eurobend GmbH installed a flexible, state of the art mesh welding line model PL XY Twin AMM BU BM with integrated bending modules for the production of special mesh, engineering mesh, mesh with openings, mesh with bent line and cross wires.

The Eurobend AMM machine works from coil and offers the highest flexibility at a very high level of automation without any changeover times. A number of innovations and unique design features make the AMM to one of the leading models on the market:

Any type of mesh can be produced automatically, immediately and without changeover and idle times.

The line and cross wires are fed into the welding portal immediately by two separate Flexiline rotor straightening and cutting machines, featuring the patented Eurobend maintenance-free 5G rotors each with eight hyperbolic rollers and with extremely fast diameter changing system. The diameter changeover takes place in less than 3 seconds without any mechanical moving parts.

Direct feeding of the cross wires into the welding portal: The complicated, maintenance intensive and susceptible common cross wire feeding systems, where the cross wires have to be produced first and then the longitudinal wires, as it is the case in the lines with one straightening machine, are no longer necessary.

Thanks to the innovative concept, the AMM machine is the most compact on the market and has a minimal floor space demand.

The AMM is equipped with a state of the art precision bending system consisting of two integrated, in-line universal bending modules for bending individually selected line and cross wires, even within openings. The special design, the servo-driven operation together with the advanced and modern software makes them technically sophisticated in this industry sector. They are characterized by highest precision and speed. Two bends are performed in 2.5 seconds with consistently precise bending geometry.

The AMM has the capability to connect to master computer for the “Just-In-Time” production, synchronized with circulating pallet systems. Another feature is the avoidance of idle times during production: during the bending process of one mesh the next one is already in progress.

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980