Construction material engineers HMP & QSI puts its trust in Darrer technology

The building material engineers at HMP & QSI GmbH have been a reliable and experienced partner in the fields of building material technology, quality assurance, building inspection, and damage diagnostics since 1983. The company offers comprehensive engineering services relating to the testing, consulting, and monitoring of building material, as well as the evaluation and assessment of buildings.

Based in Hamburg, HMP & QSI is primarily active in civil engineering projects throughout northern Germany, particularly in tunnel construction. Over the past two years, the company has continued to expand its team and now employs a workforce of more than 30 qualified staff. The engineering firm is responsible for the quality control of concrete work on numerous projects. HMP & QSI’s building material laboratory has been accredited since the beginning of 2024 and sets high standards on the accuracy of its testing procedures. In order to further increase the accuracy and efficiency of the prescribed test procedures, HMP & QSI has invested in an innovative testing device from QaverRtec in Flensburg: the Darrer.

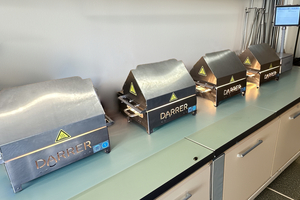

The Darrer measures the total water content of concrete or aggregate samples using thermogravimetric analysis – a precise and efficient method. Up to 2 kg of sample material can be tested per measurement, and the test results are available after just 20 minutes. The system consists of a station to which up to four units can be connected and into which the samples are poured.

The engineers at HMP & QSI became aware of the quality testing device in 2024 during an inspection of a large construction site in Denmark. There, the Darrer with four units has been in successful used for more than two years for determining the moisture content of up to four samples in parallel – precisely and reproducibly and within a few minutes.

Especially on construction sites where large quantities of concrete are processed, the Darrer makes life much easier for the team in the building material laboratory. The device saves valuable time and delivers reproducible results digitally and without calculation errors.

Another significant advantage of the Darrer technology over traditional moisture measurement methods is increased occupational safety. While conventional methods often use gas to heat the grain, this risk is completely eliminated with Darrer. HMP & QSI is thus taking another step toward modern, safe, and precise building material testing.

Quality assurance and monitoring of concrete

The Darrer was developed by Qavertec in northern Germany. With the Qaver, a device for measuring the properties of fresh concrete, the company has already demonstrated how innovative quality controls can be implemented in the concrete industry.

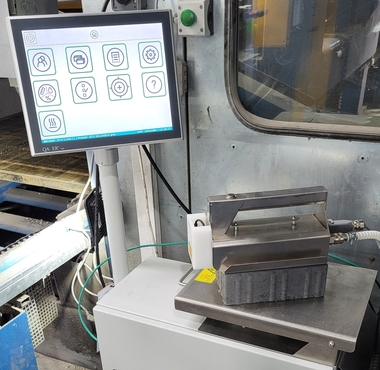

Thanks to the fully automated testing process with the Darrer, human errors, such as those that can occur during manual drying procedures or due to weighing and calculation errors, are reliably avoided. Equipped with a Windows-based industrial PC, the system is designed for continuous operation and offers a wide range of options for customizing the testing process. Sample size, test duration, and various recipes can be flexibly configured. Comments can be entered for each measurement and saved together with the results and detailed sample information, or exported as a PDF test report. Data can be output either via USB or automatically via a network connection. In addition, thanks to its open interface, the Darrer system can be integrated into existing quality assurance systems, thus supporting modern, reliable, and documentation-secure building material testing.

By using the Darrer system, HMP & QSI is consistently focusing on modern testing technology to ensure the highest quality standards. The combination of efficiency, precision, and safety not only strengthens internal processes but also provides clients with reliable and traceable results – an investment in the future of building material testing.

CONTACT

QAVERtec GmbH

Heideland 20

24976 Handewitt/Germany

+49 461 70 71 78 40

Baustoffingenieure HMP & QSI GmbH

Baumschulenweg 4

21514 Klein Pampau/Germany

+49 40 73 09 18 00