New Equipment for Ukrainian Areated Concrete Industry

The UDK Gazbeton company opens its new fully-automated autoclaved aerated concrete factory in Ukraine. The up-to-date and complete machinery and equipment was supplied, installed and commissioned by Masa-Henke Maschinenfabrik GmbH.

It all started with an idea. UDK Gazbeton based in Dnepopetrovsk - Ukraine intended to supply the local market with autoclaved aerated concrete with significantly improved properties in terms of building physics and workability than available by the existing old production plants. At the same time, the idea should meet the highest economical and ecological demands - even in future.

Since the location of the future autoclaved aerated concrete factory had already been chosen and the financial resources had been provided, it was now about searching the right partner for a reliable realization of the project

Owing to the complexity of the topic „producing autoclaved aerated concrete“, UDK was therefore faced with the first but most important decision for the success of the entire project:

» Which partner does guarantee the highest possible reliability for the project?

» Who has gained the most experience and has excellent references?

» Who does offer the best technical and economical solution?

» Who has the best knowledge of the local conditions?

» Who is locally represented with service and spare parts?

» Who has the necessary resources concerning machine engineering and manpower?

» Who does know local sources for the supply of essential plant components?

Consequently, first Chinese suppliers dropped out from the competition despite their interesting pricing policy.

European suppliers cooperating with Chinese companies were also excluded from the project owing to a lack of clearly defined responsibilities.

Then, there were only European suppliers left for making a decision.

As Masa-Henke fulfills all criteria mentioned above, Masa-Henke was awarded the contract to realize the autoclaved aerated concrete factory.

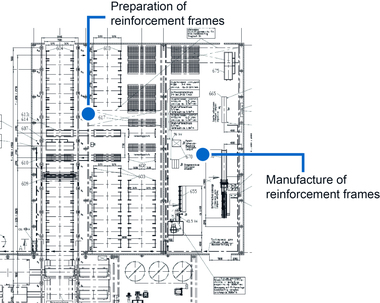

Concept of the new autoclaved aerated concrete factory

Silica containing sand, lime, cement, aluminum powder or paste, water and gypsum, if necessary, as well as additives are the raw materials for the production of autoclaved aerated concrete. In the autoclaved aerated concrete factory in Ukraine silica rich sand as well as the generally used conventional binding agents are used for the production. The valid European standards as DIN EN 771-4 are applied as quality standard for the production of the autoclaved aerated concrete products.

The binders lime, cement and gypsum are stored in silos outside of the factory building, by the side of the mixing tower. Regarding the supporting structure of the mixing tower this layout saves enormous costs compared to a solution positioning the silo above the mixing tower.

Apart from the special mix design, each single batch also has to have a corresponding temperature when poured into the mold. In order to react accordingly, there is a hot water tank as well as a cold water tank on top of the mixing tower. Thus, it is possible to react to the specific raw material requirements by adding mixing water in the respective temperature.

According to the concept of the mixing tower a scale is used for each individual raw material component. This facilitates quick and exact weighing especially in case of high production outputs. An intensive mixer follows the raw material scales. Within the mixing cycle the raw materials are added portion by portion. In particular with respect to the mixing depth of the finished batch and the chemical reaction process this aspect is of superior importance.

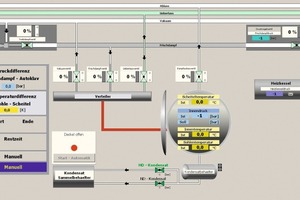

Raw material management and distribution concerning sand slurry and recycled slurry, binding agents, dosing of aluminum and addition of water is managed by a fully-automated control system. In this process, not only the quantities are controlled but also the temperature and the mixing formulations. The control system is additionally furnished with an integrated filing system for a better quality control.

The section of the fermentation area was adapted within the building structure of the factory. The building height here was designed lower in comparison to the production hall. This not only resulted in financial savings in the construction process. A constant internal temperature structure in this building section also has a positive effect on the waiting time as well as on a uniform growth process of the individual cakes. Reduction of costs and saving of energy as well as shorter waiting times are the positive effects.

At the end of the fermentation process after a defined time, the molds are transported to the cutting line. The green cake is turned from the horizontal into a vertical position with the aid of a crane in a gentle way and not damaging the structure.Afterwards the aerated concrete cake is demolded and it is passed through the cutting line.

The cutting wastes are fed to the cut waste recycling device, mixed with water up to the slurry density required and then pumped to the recycled slurry tank. The concept allows to return the recycled slurry entirely to the mixing process without any remaining residuals. Therefore, it is avoided to make use of the recycled slurry, caused by a high percentage of cutting wastes within the cutting line, in any other kind of further processing or disposal.

The finished green cake is picked up by the loading and unloading unit of the autoclave and transported to the prepositioned curing cars. The green cakes are collected in the waiting area in front of the autoclave and are put together to a string of several curing cars by means of a fully-automated curing car pulling device. The autoclave is efficiently designed in respect of size and the cross-section of feeding.

Furthermore, enormous saving potentials are achieved by vertical positioning of the cakes. The combination of hardening plates and cakes in upright position leads to an optimum effect of the steam to the cake and the resulting CSH phase generation. Remaining on the curing plate has more significantly positive effects on the green cake. After the cutting process, it is not necessary to turn the cake once more to remove the bottom layer. Before the hardening process the internal structure of the green cake is very soft and delicate. Any additional movement may result in micro damages at the cake structure, and this has a significant impact on the quality of the finished block with the consequence of more rejections.

Furthermore, the remaining bottom layer between cake and hardening plates serves as a physical barrier and prevents an additional drying and loss of heat in the lower layers (due to thermal conductivity of the metal surface on the cake). Another advantage of system is that, due to the „gentle“ transport and the low impact to the cake, the required quantity of binding agents can be reduced considerably. The cake requires a lower green strength as against other systems. This means enormous savings - financially as well as regarding the consumption of binding agents and water as well as regarding the autoclaving process.

The steam hardening process is supported by the steam control system. The optimized cycle runs fully automatically, but it can be adjusted manually by the operator at any time.

After the autoclaving process the completely hardened cake leaves the hardening boiler and is immediately transported to the packaging line. The autoclaved aerated concrete blocks are bundled in the packaging line and are shrink-wrapped fully automatically. The solution provides, in particular, good weather protection, and thus it is ensured to deliver high-quality autoclaved aerated concrete products throughout the year.

The Masa-Henke concept for UDK Gazbeton is designed not to produce any waste at all. Besides an existing return system for condensate arising from the autoclave steam system, the concept is extended by returning the cut off bottom layers and the classically damaged blocks to the production process.

The overall process in the factory of UDK Gazbeton provides individual manufacturing programs allowing to produce a wide variety of different autoclaved aerated concrete blocks.

This project designed a concept for the future taking also an expansion of the factory up to a daily output of 1,400 m³ into account. Just with a minimum capital expenditure it is thus possible to adapt the factory to the requirements of the local market in Ukraine.

To define the right goal at the beginning of a project and to choose the right partner with Masa-Henke to carry it out. These are the two factors that ensure now the sustaining economic success of UDK Gazbeton, even in economically difficult times:

» Excellent product quality concerning tolerances, compressive strength and apparent density Advantage: high acceptance of the products in the market

» Efficient and cost-effective manufacturing methods

Advantage: the product can be offered at reasonable prices

» High availability and flexibility of the pant Advantage: reliable supplies and schedules

Masa project across the world

The Masa Group with its subsidiary Masa-Henke Maschinenfabrik GmbH plans and realizes plants for the production of building materials all over the world.

Masa is a reliable partner for turning your capital expenditure into a project giving advice for modernization and efficient optimization of existing plants up to the supply of turn-key plants.

The long list of international references in the field of autoclaved aerated concrete, sand lime bricks, block making and slab manufacturing obviously prove the high degree of customer satisfaction.

Product range of the Masa Group:

» block making plants

» curbstone presses

» autoclaved aerated concrete plants

» sand lime brick making plants

» slab presses and wet presses.

Matthias Klare