Automatic mixer cleaning – a quantum leap in concrete production

With its Easycleaner, Pucest Protect GmbH has developed and launched an efficient cleaning system for concrete mixing plants that is ready for series production. In practice, this innovative, automatic high-pressure cleaning system is proving itself with impressive performance. A field report shows how use of the Pucest Easycleaner directly contributes to optimized production processes – in several ways.

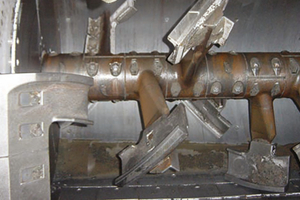

The concrete plant manufactures around 450,000 m² slabs at the company headquarter. The heart of the production facility is a modern concrete mixing plant with a 1.5 m³ pan mixer dating from 2014. Pucest was able to improve this reliable technology in several ways, as the plant manager confirms. The mixer conversion, carried out with optimally adjusted universal mixing arms from Pucest, led to a 50 % reduction in mixing times.

It should also be emphasized that the conversion leads to an optimization of the homogeneity of the mixture, which enables quick and clean emptying of the mixer. “With old systems, only solid material flows out when the mixer is first opened, followed by thin soup,” explains the plant manager. Not only the quality of the raw materials and the precise adjustment of the mixer, but also ideal, regular cleaning are essential prerequisites for ensuring consistently high quality of the mixed material.

The staff at the concrete plant are also fully aware of these requirements. In the course of mixer conversion and use of the Easycleaner, this system also optimizes workflows at a high level in the process chain. Here, the same as in the entire process chain, the concrete plant applies the highest standards as well. Requirements could not have been stricter when it came to improving workflows.

Expectations exceeded

To reliably prevent residues of viscous cement slurry from hardening in the mixer, the mix master cleans the mixer every four to five hours. Until now, these tasks have been carried out manually, with employees working directly in the mixer trough while wearing protective clothing and equipped with a high-pressure cleaning lance.

It was not uncommon that follow-up work required climbing into inaccessible areas of the mixer with heavy tools. This usually took a worker up to 45 minutes – with a corresponding loss of production. This situation made the concrete plant highly receptive to genuine innovations – which were, of course, received skeptically at the beginning.

When Pucest first offered its Easycleaner, the plant manager thought: “They’re really going out on a limb with their device and what it’s supposed to be able to do! If it’s even half as good as claimed, that would be great.” Now, after a few months in operation, he adds: “The Easycleaner has actually exceeded Pucest claims.”

During normal intermediate cleaning, which takes only about one minute, more than 80 % of residues are removed. Three high-pressure cleaning heads in the cover of the mixer trough carry out the cleaning with a water pressure of only 160 bar.

In addition, the Easycleaner enables freely configurable dosing settings for intermediate cleanings, which are now carried out every hour. Intermediate cleaning is set and started using the intuitive menu on the touch display at the control unit.

Efficient cleaning and more

The flexibly programmable dosing function on the Pucest Easycleaner also enables further optimization of a different kind: Especially in summer, high temperatures cause aggregates to become so dry that they form a homogeneous mass during pre-mixing, which makes it difficult to mix in water afterwards.

Instead of folding the cement-sand mixture into the water, the mixture is conventionally pushed forward. The Easycleaner eliminates this problem. During each mixing process, the aggregate mass is moistened for about 15 seconds during the pre-mixing process via the cleaning heads of the Easycleaner. This procedure makes it easier to gently fold in the water during the mixing process.

On request, a moisture sensor for monitoring the residual moisture in the concrete can be installed in the mixer. This ensures that the maximum amount of water specified in the mixing formula is not exceeded. “With further development of the Easycleaner from a high-pressure cleaning system to a simultaneously integrated humidification system, Pucest has implemented the program selection for water dosing as a standard feature for monitoring the residual moisture in the concrete.”

“This technically important advance in the Easycleaner is proving to be a valuable solution to problems, as experience by all users has shown,” explains Pucest Managing Director Detlef Bauer.

Added value recognized

Since it went into operation in June, the system has become a valuable part of production at the concrete plant, and no one involved wants to work without it now – from plant management to users. The mix master sums it up: „Until now, cleaning the mixer every day was an unpleasant job and potentially harmful to health due to dust and odors – but with the Easycleaner, that’s now a thing of the past. In addition to improving working conditions, we now need to factor in significantly fewer staff hours for the necessary cleaning work.

Thanks to the significantly optimized process routines resulting from shorter cleaning times and pre-dosing humidification, we have achieved an increase in efficiency that will quickly pay for investment in the Easycleaner. Its use in the concrete plant impressively demonstrates how consistent use of all the capabilities of the Pucest Easycleaner both optimizes the production process in a measurable economic way and makes the workflow more user-friendly.”

CONTACT

Pucest Protect GmbH

Im Höning 11

63820 Elsenfeld/Germany

+49 6022 264010

https:/pucest.de