High-performance concrete screws for demanding fastening applications

16.12.2025

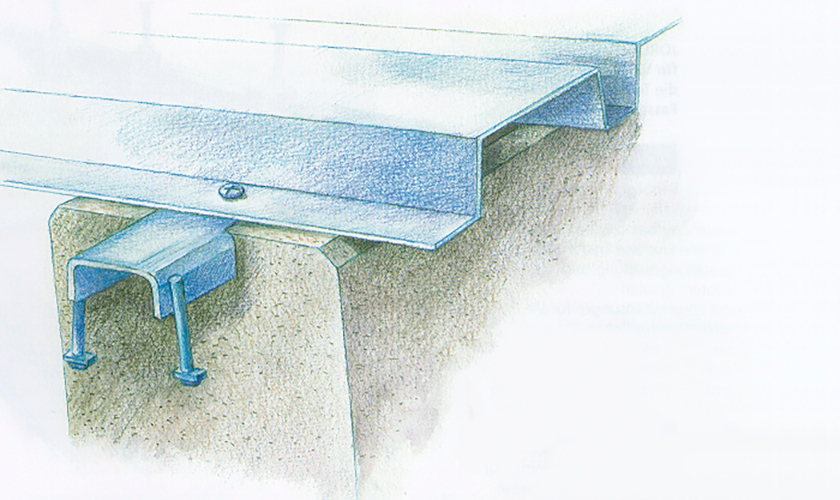

Figure: Toge Dübel

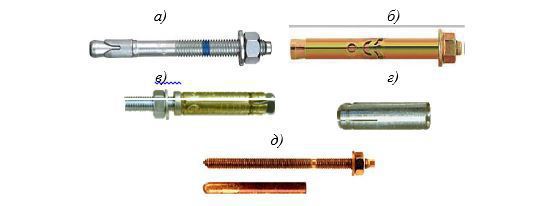

Concrete is one of the most important building materials—and places high requirements on fastening systems. Classic solutions such as hammer-in anchors or bolt anchors offer security, but require several installation steps. Concrete screws, on the other hand, combine high load-bearing capacity with efficient and completely reversible installation.

Figure: Toge Dübel

Concrete is one of the most important building materials—and places high requirements on fastening systems. Classic solutions such as hammer-in anchors or bolt anchors offer security, but require several installation steps. Concrete screws, on the other hand, combine high load-bearing capacity with efficient and completely reversible installation.

The requirements for fastening systems arise primarily from the special properties of concrete. It reacts to loads, temperature changes, and moisture, which can lead to internal stresses and small cracks, especially in the area of drill holes. Its material properties, such as strength class and age, as well as environmental conditions, determine the fastening. This must withstand high mechanical loads – such as tensile, shear, or bending moments. Strict requirements apply, especially in cracked concrete.

For tradespeople, installation time is crucial: high labor costs require fastening solutions that can be installed quickly and easily. While expansion anchors require several steps and considerable force, concrete screws are simply screwed in and cut their own threads. They can be removed at any time, making them ideal for temporary anchoring. Small center and edge distances also allow for installation close to the edge.

Double hardening for greater safety

Another advantage is that concrete screws can bear high loads, making them suitable for a wide range of applications such as railings, brackets, or tracks. The Toge TSM High Performance, for example, is approved for concrete strength classes from C20/25 to C50/60 as well as for cracked and uncracked concrete and can also be used in prestressed concrete hollow slabs, masonry, or natural stone. The double hardening process plays a special role: the screw body of the TSM High Performance is given a basic hardness, while the tip is induction hardened. Depending on the area of application, galvanized or stainless steel variants are available. Thanks to different head shapes, the right solution can also be found visually.

High-performance screws must undergo extensive testing procedures. Products with ETA approval (European Technical Assessment) are designed for a service life of 50 years. Advances in development lead to regular updates of the technical documentation—such as the currently investigated goal of eliminating the mandatory cleaning of drill holes.

Even though alternatives to concrete are increasingly being researched due to its CO₂ balance, concrete screws remain a central element of modern fastening technology. In the future, universally applicable concrete screws will cover additional substrates and a modular design, thus simplifying storage and application.

Conclusion

Concrete screws enable fast, secure, and reversible fastenings in concrete—especially in confined spaces and under high load requirements. Extensive approvals ensure the safety of the connection solutions and their long service life.

Text: Niklas Barlovitz, Product Manager at Toge Dübel

CONTACT

Toge Dübel GmbH & Co. KG

Illesheimer Str. 10

90431 Nuremberg/Germany

+ 49 911 659 68-0