Spurgin and Progress Group: A double wall success story in France

Spurgin stands for innovation, sustainability, and efficiency in precast production. Being the French market leader for prefabricated conventional and low-carbon double walls, the company develops future-proof solutions – supported by its partnership with Progress Group. Together, the partners install state-of-the-art carousel plants, most recently in Mignières in northern France, where a new facility for producing wood concrete elements containing 85% of bio-based materials was set up.

Spurgin has been synonymous with innovative and efficient solutions for precast double walls since 1978. Setting a strong focus on simplification, quality and sustainability, the company develops demand-driven products for the construction sites of tomorrow – and has meanwhile become the market leader in France. Operating a total of seven pallet circulation systems in six locations, Spurgin is one of Progress Group’s long-standing customers. The partnership established in 1998 is based on mutual trust and the common goal of producing low-emission precast elements efficiently and innovatively. Offering 15 different products in four demand-driven segments, Spurgin places particular emphasis on innovative solutions that enhance the carbon footprint while ensuring high-quality finished products, including insulated and non-insulated double walls, architectural walls made with form liners or colored concrete, and precast slabs and solid walls in wood-concrete.

Figures illustrate a long-standing partnership

Progress Group installed the first carousel plant for Spurgin in 1998 in the French Alsace region, near the company headquarters in Sainte-Croix-en-Plaine. In 2004, Spurgin launched the Isopré wall with integrated insulation and built another plant in Blyes, south-east of its headquarters, which is now the company’s third site. This was followed by the fourth plant in Chartres (Mignières) in 2011 and the fifth plant in Nesle in 2017 to better serve the Paris market as well as the west and north of France. Just one year later, the sixth plant opened in La Roque d’Anthéron near Marseille to exploit the full potential of southern France. In 2023, the double-wall carousel line on the Sainte-Croix-en-Plaine site was completely rebuilt and elevated to the latest standards. Over time, the carousel plants were partially upgraded at regular intervals – with a special focus on the fully integrated reinforcement machines – to optimize production further.

Pilot project: Plant for bio-based wood-concrete elements with low CO² content

The most recent joint project was implemented in Mignières in northern France and includes a new plant to produce wood concrete elements that leave a sustainable footprint and are made from bio-based materials. New legal requirements in France prompted Spurgin to launch this specially designed solid wall. Support mainly came from Ebawe Anlagentechnik, the specialist for carousel plants within Progress Group. Automation for the specific production requirements was implemented by installing innovative machinery and software solutions.

In collaboration with Spurgin and CCB Greentech, a concrete spreader for spreading wood concrete and a special device consisting of a spiked roller and tamper were designed, which ensures levelling and appropriate compaction of the wood concrete. The installed turning equipment can pick two pallets at the same time and turn them about 180 degrees. This allows for a load-bearing structure made of standard concrete to be applied to the top of the wood concrete element.

PreFix shuttering system as the centerpiece of the new setup

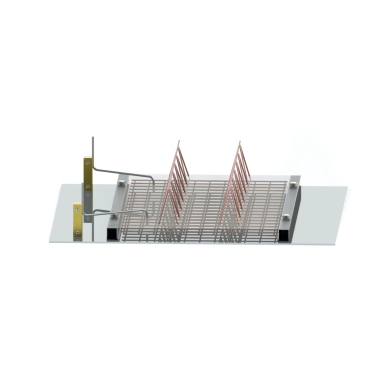

Progress developed a FormMaster shuttering and deshuttering robot that features the PreFix shuttering system to cater to the requirements of the new type of solid wall. One of the major challenges in this project was to be able to flexibly produce different wall thicknesses and contours. Due to the substantial number of combinations, a conventional shuttering system would have occupied an enormous amount of space in the shuttering profile store.

The revolutionary PreFix shuttering system consists of a universal basic shuttering system equipped with magnets and various facing elements, which the shuttering robot exchanges fully automatically. This combined system makes it possible to produce elements with different wall heights and contours on each pallet. The need for shuttering elements is reduced significantly so that considerably less space is required in the warehouse.

The shuttering is removed before the elements harden using a deshuttering robot, which is made possible by the dimesional stability of the wood-concrete after compaction. As a result, only a fraction of the shuttering elements is required compared to the conventional setup.

Digitalization of production workflows

The entire system is supported by the Ebosyc software solution, thanks to which the warehouse robot can assemble the required shuttering in advance – without any waiting time when switching to another wall height or thickness. Another top-class feature is the innovative 3D visualisation via the Graphical Performance Analyzer (GPA), which enables clear and location-independent monitoring of the entire production process. Complete visualisation and intuitive operation ensure a seamless production process. Ebosyc also allows for flexible pallet allocation and production control.

First wood concrete elements after just three months of construction

Once the shuttering is in place, the concrete is discharged through the spreader, levelled, and compacted. A storage and retrieval unit places the pallets with the previously demolded elements in the curing rack. Double wall elements produced with the aid of the turning device are moved into an almost vertical position and lifted using the tilting equipment.

The complete carousel line was installed and commissioned successfully within just three months – a challenge that only a well-coordinated team could master. This project marks a major milestone for the French construction industry, and Progress Group will continue to utilize its ingenuity to support Spurgin on its path toward automation and digitalization of precast production.

CONTACT

Spurgin Leonhart SAS

Route de Strasbourg

B.P. 20151

67603, Sélestat Cedex/France

+33 3 88 58 88 30

EBAWE Anlagentechnik GmbH

Dübener Landstr. 58

04838 Eilenburg/Germany

+49 3423 6650

Progress Maschinen & Automation AG

Julius-Durst-Strasse 100

39042 Brixen/Italy

+39 0472 979100

Progress Software Development GmbH

Via Julius Durst 100

39042 Brixen/Italy

+39 0472 979159