Precast Data Validator: How Allplan Improves Data Quality in Precast Design

Faster, cheaper, and more precise – that’s the current mantra in the construction industry. And this is all happening with fewer skilled workers and increasingly complex construction projects. One possible solution is reliable software that delivers high-quality data right from the design phase. The optimized Data Validator does just that, using sophisticated checking rules to simplify the daily work of precast designers and detailers. Read on to learn how a pilot project with international customers became a highlight of the current version of Allplan 2025, offering benefits to all users.

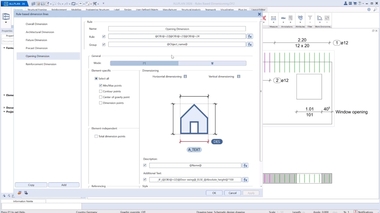

Freely configurable check rules ensure maximum data quality

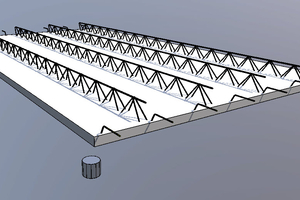

In prefabrication, even the slightest oversight in planning can result in costly delays, manual rework, or dangerous situations on the construction site. This makes it all the more important to detect potential design errors early on. Wolfgang Gigelleitner, Head of Technology, DEWA, and CAD/CAM at Franz Oberndorfer GmbH & Co. KG, emphasizes, „The Precast Data Validator ensures that we minimize errors in the precast design and detailing phase. For example, the Data Validator can check whether prefabricated slabs contain a certain minimum amount of reinforcement, depending on the span.“

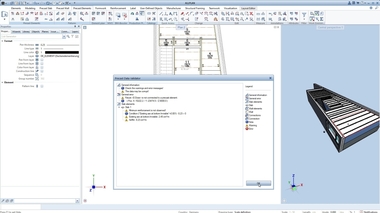

The Data Validator checks parameters individually at defined times. For example, it can be used during detailing or before production data is generated. This guarantees that only accurate and verified data enters the precast production process.

Allplan automatically performs the following checks:

What is the exact weight and volume of the precast elements?

Is a certain minimum reinforcement required depending on the respective dimensions?

Are there any fixtures on the drawing file that do not belong to a precast element?

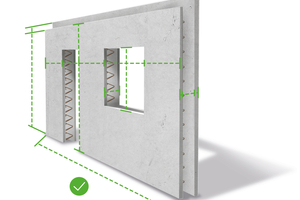

Has the correct girder height been selected for double walls? Is the in-situ concrete core large enough?

Has the maximum weight of the precast elements been exceeded?

These checks can be adapted to the specific needs of the precast manufacturer. Of course, new rules can also be created as needed. The subsequent steps to be taken in the event of a rule violation can also be defined. For example, should the designer simply be notified of the anomaly? Or, should production data no longer be exported in the event of certain rule violations? What if the wrong concrete grade has been selected, for example? These options ensure that plant- and project-specific standards and requirements are considered.

Substantial benefits for precast manufacturers

The Data Validator was developed as a pilot project in collaboration with two precast plants: Franz Oberndorfer GmbH & Co. KG from Austria and Rector Lesage SAS Mulhouse from France. Oberndorfer is the largest precast concrete company in Austria, employing more than 900 people across 11 European locations. Rector Lesage was founded in 1957 and now has over 1,200 employees at 25 locations in Europe.

The daily requirements of the industry played a key role in the development of the Data Validator. One important challenge the construction industry is currently facing is the ongoing shortage of skilled workers. This often results in a lack of qualified production employees who can identify errors early on and take countermeasures. Against this backdrop, it was all the more important to incorporate sufficient quality checks into the software during the planning phase. This prevents time-consuming rework and faulty production.

At the same time, safety is increased for everyone, whether they are working in the prefabrication plant, on the construction site, or transporting materials. Armand Hausser, head of the engineering office at Rector Lesage, summarizes: „The software is no longer just a means to an end—it is an important additional safety mechanism. This means that even less experienced employees can rely on the production data.“

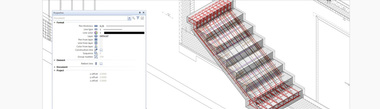

DfMA and the Future of Precast Design and Detailing

Taking production and assembly on the construction site into account as early as possible in the planning phase is known as Design for Manufacturing and Assembly (DfMA). For Allplan, this way of thinking is a fundamental part of its corporate philosophy: the „Design to build“ approach. With the help of a single platform, construction projects can be planned and built from start to finish. Seamless, cloud-based collaboration between all project participants is just as much a matter of course as data-based decision-making, digital manufacturing processes, and working with BIM models. Allplan‘s automated quality controls help precast plants to future-proof themselves amid shortages of skilled labor and low margins.

CONTACT

ALLPLAN Österreich

Urstein Süd 19/1/401

5412 Puch bei Hallein/Austria

Christiane Ganster-Rathgeb

Allplan.com/precast