Powerful precast design with Allplan Precast 2026

Plan more in less time – that‘s what the new developments in Allplan Precast 2026 are all about. Users can look forward to significantly faster precast design: shorter loading times, even for complex precast models, and faster updates to models, plans, and drawings deliver even greater performance and speed for precast planning. Other highlights include rule-based dimensioning, local views and sections, innovations in the connection palette, greater sustainability through void formers for hollowcore slabs in ceiling systems, simpler quantity take-off, clearer reinforcement plans, and numerous other new features.

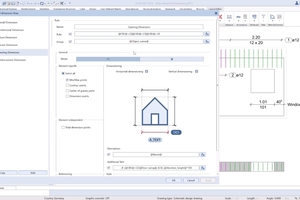

Faster creation of production-ready drawings

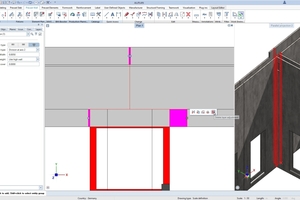

Allplan 2026 now offers automated and rule-based dimensioning. Instead of time-consuming and error-prone manual dimensioning, users now simply specify which information is required in the respective plan section. This ensures that dimensions are placed exactly where they are needed. This automated creation significantly speeds up the dimensioning process and ensures that each precast element receives exactly the required dimensions in accordance with customizable rules and standards. In addition, rule-based dimensioning noticeably increases the accuracy and reliability of documentation. This is because the optimized update behavior minimizes errors and eliminates potential oversights.

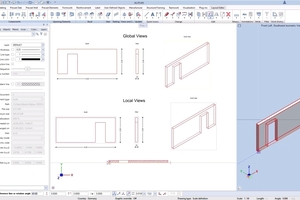

Practical: Local views and sections

With the newly developed local views and sections, element-related plans can now be created efficiently, independently of the overall data model. Local views represent elements in their local location, regardless of their position in the overall building. This means that the placement of views and sections remains unchanged even if the location of the element in the room changes. This fundamental technology is essential for the precise and flexible planning of individual components in construction and significantly improves the reliability and efficiency of workflows.

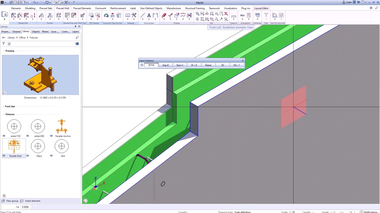

Easier handling of connections

The new connection palette, based on modern Windows Presentation Foundation technology, enables significantly more efficient working thanks to its more compact and clearer layout. Connections can now be modified more easily, ensuring a smoother and more efficient workflow. This innovation helps to create a uniform operating concept across all components in Allplan, enabling new users in particular to learn more quickly. In addition, intuitive handles have been introduced that allow direct geometry changes to the connections, enabling immediate visual control. This makes the adjustment of prefabricated connections even easier and more user-friendly. The connection palette thus ensures a noticeable increase in productivity during planning.

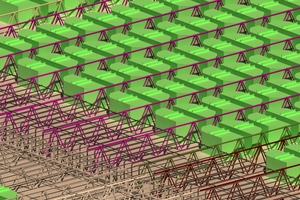

Hollow bodies for greater sustainability

Allplan 2026 introduces an unprecedented level of automation and prefabrication for sustainable hollowcore slab design and implemention. For example, the new Unidome XP product line – developed in collaboration with FDU specifically for use in prefabricated element slabs (semi-finished parts) – can be used for this purpose. The XP void formers are precisely integrated into the element slabs during production in the precast plant. This not only saves time and labor, but also reduces the total concrete use by up to 25% without compromising the load-bearing capacity. The resulting weight reduction enables slimmer columns, foundations, and walls. Unidome XP void formers are made from 100% recycled plastic.

„At Unidome, we have made it our mission to identify specific areas in reinforced concrete components where material can be saved. With over 25 years of experience in hollow core technology, we are not resting on our laurels: we are continuously developing ourselves and our products to make concrete construction more sustainable, efficient, and future-proof,“ emphasizes Dr. Karsten Pfeffer from Unidome Deutschland GmbH.

Automated material calculation in IFC4precast format

Individual quantity take-offs have long been standard practice in the precast concrete sector. In the past, data was exchanged between CAD and ERP systems via various file-based interfaces such as ADS, PXML Delegate, or CPI-XML. However, with the increasing use of BIM planning, there is also growing demand for ERP systems that can process graphical information. The key players in the precast industry – including Allplan – have developed IFC4precast, a universally recognized, uniform format for the exchange of model-based data for precast elements. This standard definition enables the exchange of commercial data in the modern IFC4Precast format. This ensures seamless, future-proof data transfer and significantly improves integration between the planning and commercial departments.

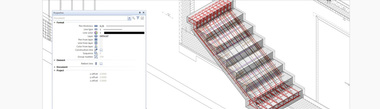

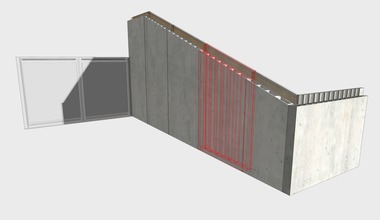

Clearer reinforcement plans

Allplan 2026 enables the calculation and display of concealed reinforcement information in views and sections. This saves time, as the views are now generated fully automatically and do not have to be derived from the model in a separate step. Views can now be generated with only the protruding reinforcement bars. If desired, the hidden part of the reinforcement can be displayed in a different color or as a dashed line. This improvement significantly increases the display quality of reinforcement plans and supports more precise and efficient component production.

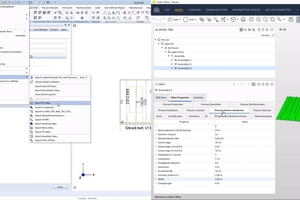

Element-specific evaluation at the touch of a button

Manually searching for and comparing components is now finally a thing of the past. The new database solution for item numbers in Allplan 2026 enables faster and more efficient creation of items for all elements. This gives you a constant overview of which components are actually the same, regardless of which floor the elements are on or whether the floor needs to be loaded at the current time. This innovative solution was designed for all types of components and is now available in version 2026 for selected prefabricated elements, such as fixtures, assembly groups, and welded mesh reinforcement elements.

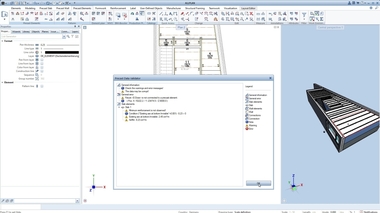

Connections made easy

The new connection update also makes everyday planning workflows much easier. Now, when elements are created in Allplan 2026, structural analysis printouts are generated at the same time, removing the need for a separate program. This significantly speeds up the verification process and minimizes the risk of errors. Partial safety factors can be customized and thus easily adapted to international standards. In addition, individual spacing for diagonal and horizontal anchors allows maximum freedom when planning prefabricated parts. The connection update is available for the current version of Schöck Isolinks 2026, as well as for other well-known manufacturers, such as BT Innovation, Green Code, and Kappema.

Allplan 2026: Plan precast elements faster and more precisely

Quick, resource-efficient planning is more important than ever. With Allplan 2026, productivity reaches new heights thanks to improved performance and faster, more streamlined workflows. The latest release once again proves that for Allplan, digitalization, automation, and sustainability are more than just buzzwords – they’re built into everything we do.