Largest producer of hollow-core slabs in the UK continues to grow

Creagh Concrete, one of the major British manufacturers of concrete goods, started with the production of concrete blocks in 1974 and has developed into a leading manufacturer of precast concrete elements and prestressed concrete components. Recently, the BFT editorial staff personally obtained information at the Ardboe plant in Northern Ireland.

The Creagh company, one of the major British manufacturers of concrete products, founded by the McKeague family, started with the production of concrete blocks in 1974 and has developed into a leading manufacturer of precast concrete elements and prestressed concrete components. The company has locations in Hoveringham (England), Edinburgh (Scotland) and in Toome and Ardboe (both Northern Ireland); the delivery area expands all over Great Britain and Ireland. Characteristic of Creagh is the constant striving for product innovations, for example, with Spantherm, a thermally efficient flooring system, and Rapidres, an off-site fast-track build system. As a leading manufacturer of hollow-core floor slabs, Creagh is committed to quality and excellence and, therefore, is continuously investing in innovations.

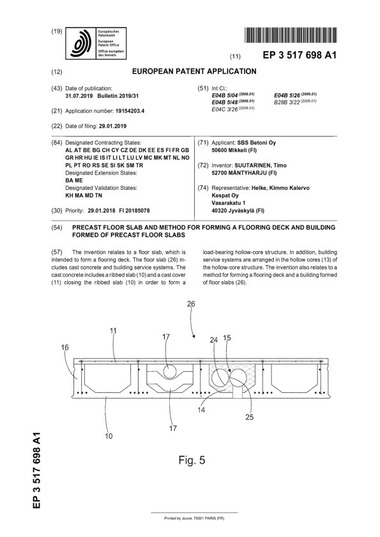

The most important product at the Ardboe facility are precast prestressed concrete hollow-core slabs featuring a thickness from 150 to 500 mm as well as 100 mm thick solid wall panels. Two mixing plants (with a capacity of 1.25 m³ each) can produce 210m³ of concrete per day. The storage capacity on the entire premises covering 16 hectares corresponds to an area of four football fields and more than 25,000 m² of floor slabs, respectively.

In addition, last year, Creagh manufactured more than 8,000 precast concrete stairs and more than 2,000 other concrete elements such as precast foundation beams and terrace units. The planning team, consisting of about 50 employees, is planning 15 prestressed concrete beds for production every day, using the software of i-Theses for this purpose.

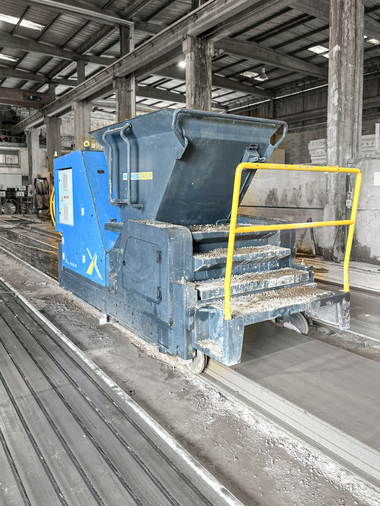

The company has recently decided to increase the production output at the facility in Edinburgh/Scotland because of the growing demand in the market. The decision was made in favor of two new Extruder X-Liner machines of Progress in order to expand the capacities, to enhance the quality and to reduce waste as well as to take better precautions for occupational safety and health (see also BFT 12/2023).

Automation for progress

Creagh Concrete is present in numerous market segments, including education, residential and commercial construction, as well as in correctional facilities. At three operating sites, the company is producing their own mineral aggregates which are used in the production of the concrete elements. The hollow-core floor slabs produced are used in a wide variety of projects – ranging from the construction of single-family homes up to the larger projects such as housing complexes and school buildings. With a production capacity of more than 600,000 m² per year, Creagh Concrete is the largest manufacturer of hollow-core floor slabs in Great Britain and Ireland. In the 1990s, the company started with the prefabrication of these elements. At that time, they acquired a large factory site which had a slipformer machine installed by the previous company owner. Then, they got in contact with the Belgium equipment supplier Echo and purchased another slipformer to be able to manufacture hollow-core floor slabs of a high quality. For the plant expansions in the subsequent years, they contacted Echo once again to purchase further equipment, with which the process could be made much more efficient.

The extruders are operating even more reliable than the slipformers, the curing time is shorter and the risk of delamination is lower. The Extruder X-Line machine is consistently producing a very good slab quality, reducing waste considerably, which is good for the environment and in terms of costs.

New equipment for saving time and costs, with reducing waste

The semi-automated production had reduced their labor costs by 10%. The hollow-core floor slabs made are lighter by 30 kg/m², resulting in another 10 % of savings on transport – all in all, these are significant advantages in efficiency with an improved product quality simultaneously. In respect of occupational health and safety, there is less noise and less risk of strand slippage to be emphasized. Thus, creating a safer work environment.

„All facilities manufacturing our products are operating according to the same first-class quality standards with common procedures and management. All of them are certified in accordance with ISO 9001 and ISO 14001 for our production and environmental standards. This means that our products and services are safe and reliable, providing superior quality,“ explains Seamus McKeague, CEO at Creagh and former president of IPHA for a long time. „Creagh is not only a concrete producer, but also provides a service, that begins with establishing a relationship with our customers. In this way, we can provide a custom-made experience from initial design consultation to project completion and even beyond. We adopt this approach in all our interactions, including sub-contractors and suppliers. These relationships are the key to our business and our approach of collaboration to deliver successful projects. In addition, we offer a comprehensive technical support service with efficient, detailed advice and support on site.“

Creagh Concrete does not have to fear the future neither because the next generation is already on board: Kevin McKeague has meanwhile followed in the footsteps of his father Seamus and has taken his position at the board of IPHA since the last annual conference in Warsaw in May 2025.

CONTACT

Creagh Concrete Products Ltd

38 Blackpark Road

Toomebridge

BT41 3SL Co. Antrim

UK (Northern Ireland)