Floating concrete

With new, modular concrete production techniques that enable high-precision ex-works at low production, transport, and erection costs, magnetic levitation train technology is being touted as a robust competitor to buses, trams, subways and commuter trains. Graft Architecture explored the potentials of the system in a design study with the manufacturer – and the following is a research report.

New infrastructure that can deliver high capacity and reliability is often impossible to integrate, especially in urban areas. Underground train networks are so expensive that they are rarely built. Trams must share the available space for traffic with cars, which often prevents rapid transport.

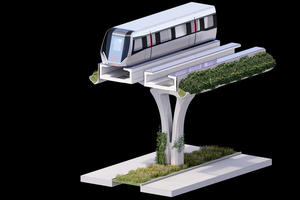

Magnetic levitation trains, with their quiet, vibration-free, and emission-free operation, on the other hand, offer great advantages for updating urban infrastructure: they travel fast and quietly on a narrow concrete track and produce a minimal footprint. Their slender supports and point foundations touch the ground at intervals of approximately 25 m. Which means that the space required at ground level is small and construction is relatively simple compared to ground-level rail systems and the complex tunnels required for underground railways. The system can be easily integrated into urban spaces in densely used areas – or in underused areas such as median strips. Their elevated structures allow building over road intersections or other obstacles. From the authors’ point of view, these elevated systems also offer the opportunity to rethink the city and to make previously unused areas available for residents.

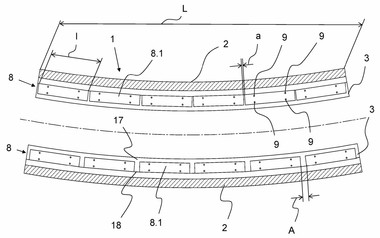

The TBS, developed by Max Bögl GmbH, is a system that can be manufactured in modular fashion and was specifically designed for the construction of trackways. It is necessary to construct the complex concrete cross-section of the trackway so as to support a span of 12 to 24 m, in such a way that inclines, curves and radii can be precisely represented in multiple axes (see Bögl/TSB box).

On the basis of these principles, Graft Architects has developed design projects for supports, track and stations and, using intelligent track technology, has also explored potentials for generation of solar energy as well as track vegetation for a positive contribution to the microclimate. Based on this vision, Graft Architects developed a number of design possibilities to integrate this system into the urban environment and for the creation of new areas in urban space.

In addition, the designed stations are intended to create new spaces in urban areas that will give the mobility of tomorrow a new identity.

Urban space

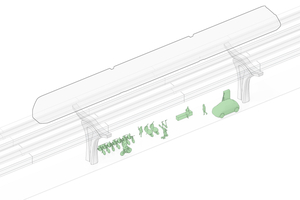

The elevated track is positioned within the existing road space on slender supports that – compared to already existing elevated train rail lines (e.g., in Berlin) – are significantly higher. The track itself consists of slender support profiles with integrated magnetic technology, which allows sunlight to pass through. The space below looks bright and unobstructed, making it especially suitable for uses that promote quality of life in densely populated cities. In addition to social activities such as at markets and sport venues, these spaces can also serve as parking areas for charging stations and other mobility services. A permanently weather-protected or shaded walkway, or jogging track, is also easily conceivable.

But the narrow footprint provided by the concrete supports can also be used in other ways. It can – if sufficiently high – form traffic islands, or enable relocation under the magnetic levitation tracks of components of existing lanes for bicycles or motor vehicles to save space. Overall, this opens up opportunities to reorganize urban traffic in a generously wide road cross-section and to reclaim space for cyclists and pedestrians.

Design the curve

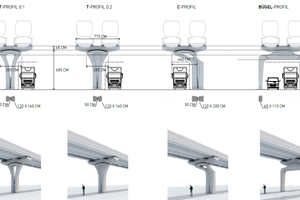

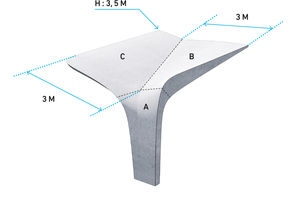

The designs of Graft Architecture envisage a slim and dynamic support structure that takes into account engineering requirements for flexible inclinations of the track in modular construction. The column head forms the support for a crossbeam that can be adjusted lengthwise and crosswise in keeping with the course of the track. The column head is designed so that the support of the crossbeam and the track itself can be adjusted in radial shells to the necessary guiding path of the track. The parallel tracks can be mounted in such a way that the escape route in the middle can always be positioned horizontally, thereby meeting the relevant safety criteria. The standard support forms a striking sculpture, which offers a high degree of transparency, with its “eye” enabling visual relations in the urban space.

Owing to its modular, serial production, the design of the route has a high recognition value on all sections of the track. At the same time, this offers a considerable advantage in production, because always the same components can be manufactured, which can then be positioned in their specified position in the urban space in the individually required inclination and alignment of the railway routes The number of different components and casting molds is efficiently simplified with this design.

The column head, manufactured in the same manner, allows various column-support positions. If, for example, the column is positioned offset from the center axis and the trackway is supported, cantilevered to one side, above the existing trackway. Vehicle space can thus also be shifted to favor public space, in the sense of urban squares.

Advantages over steel

Compared to classic elevated railway constructions made of steel, which make the space below appear dark with their numerous support profiles and bracings, the proposed system with its open and smooth concrete surfaces creates a much more pleasant space below. With respect to pigeon protection, the system offers virtually no space for pigeons to roost or shelter. Unlike conventional structures, the TSB is narrower, and it casts less shade, generates less pollution, and avoids the otherwise typically inhospitable residual spaces.

However, an elevated mobility system in urban areas also offers additional potential for greening and energy generation. Graft proposes supplementing the track with a lateral band of fiber-reinforced concrete components equipped with photovoltaic panels that can generate electricity. Due to the length of the respective routes, this results in considerable areas that can be used for energy generation. This also includes the horizontal surfaces on the track. Since the magnetic levitation train hovers several centimeters above the track, panels can also be placed there. According to initial calculations, up to 43% of the energy required to operate the magnetic levitation train can be generated on the track itself, on an annual average.

Alternatively, the side extension elements can be vegetated and, with rainwater retention, contribute to cooling urban space and to the urban sponge principle. Plants and moisture improve the urban climate. Excess water can also be directed to planted areas at the base of the supports, thereby promoting vegetation growth in the street space and on the lightly irrigated areas under the roadway. Compared to conventional trams, the areas freed up can be unsealed and used as infiltration areas. Here, too, there is considerable potential for energy generation and sustainable rainwater management.

Stations

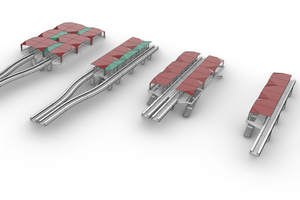

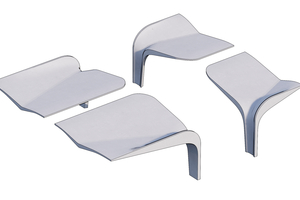

The fully automated trains create new intersection-free transfer points to existing modes of mobility at their stations. The stations will become new urban hubs and anchor points in urban space. The principle of serial concrete forms is also used in the design of the stations and is translated into a system of modular shells that can protrude in a row in various widths to form different sizes and geometries for stops. Linear seriality is used to vary a typical motif of station buildings, with the vaults lining up to form an exciting and recognizable spatial structure.

Here, too, the initially complex formwork construction can be made cost-effective by manufacturing a large number of identical parts. The cantilevered elements create additional freedom in the arrangement of many possible variations, resulting in a recognizable spatial structure.

Depending on the space requirements in the urban areas, the system can be used to create stations with central or vertical platforms. The combination of components significantly reduces the high forces that would otherwise occur in the column bases. The platform is separated from waiting passengers by automatic doors. This creates the possibility of placing light supplementary supports on the level of the automatic platform doors.

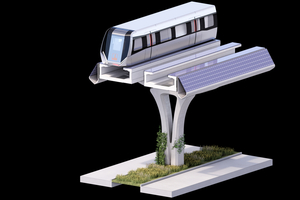

Prototype

As a prototype for a future station, a roof system is being planned for the existing TSB test track in Sengenthal – the site of the headquarters of the Max Bögl Group and one of its precast plants in Germany – that offers all these features and that can provide a glimpse of future stations.

The automatic door system will be put into operation there for the first time and, together with the shell construction, will form a structural unit. For this purpose, the shape has been further optimized in terms of water flow and the combination of elements. All elements can be broken down into elements to enable transport without major effort.

The aim is to manufacture all the prefabricated components in advance to shorten the subsequent construction process onsite. Apart from the construction of the local foundations, this means that intervention and construction time on site remain extremely short. Even maintenance can be carried out without construction site facilities. The conquest of the third dimension in urban space thus becomes a leap in quality for all city dwellers, combining mobility intelligence and the enhancement of public spaces.