Design approaches for sustainable concrete mixes and structural components (P. 2)

Changes in the current use of concrete materials and design approaches are mandatory in order to comply with the requirements imposed on future sustainable concrete structures. Before this background, the article indicates the design of sustainable concrete mixes (green concretes or eco-concretes) and the structural components made from them. Part 1 was already published in BFT issue 8/25, read here Part 2.

3 Sustainable concrete mixes

3.1 Approaches

In order to meet the requirements of sustainability concerning concrete as a building material, the currently used concrete compositions must be fundamentally changed. In particular, the Portland cement clinker (PC), which is associated with extremely high CO2 emissions, must be substituted as far as possible by more environmentally friendly binders, for example, secondary cementitious materials (SCM) and/or new types of hydraulic binders. Further, substitution with inert fines of aggregates is also a very promising approach to significantly reduce the carbon footprint of concrete mixes.

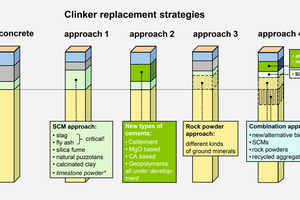

(Figure 4) summarizes the different strategies for clinker replacement by subdividing these strategies into four different kinds of approaches. The composition of ordinary structural concrete in volume parts is indicated by the first column (left). Apart from the aggregates which comprise a volume of approx. 70 %, the remaining 30 vol % are filled by water, cement (or substitute products), additives and admixtures.

Approach 1 (see (Figure 4)) shows a pronounced replacement of the cement by SCM additives. The materials blast furnace slag (BFS) and fly ash (FA) – being often used today – must be viewed critically. BFS is a by-product of steel production. Therefore, its availability is limited and BFS may be unlikely to replace PC completely due to the huge amount of PC which is needed worldwide. FA is a waste product resulting from coal combustion. However, the energy generation from coal combustion is extremely problematic due to the high associated CO2 emissions. Therefore, this type of energy is coming to an end in a continuously increasing number of countries. This means that FA will become more and more scarce in the concrete industry and will no longer be available at some point in time. Silica fume (SF) is also a by-product having a very limited availability in the market. The other SCM mentioned in (Figure 4) (approach 1) can be expected to increasingly enter the market. However, there is still a considerable need for research in the area of calcinated clays.

Approach 2 (see (Figure 4)) assumes that Portland cement clinker will be completely replaced by new types of cement/binder. In addition to the product Celitement (Stemmermann et al, 2020) these are primarily MgO- and CA (= CaAl)-based binders as well as geopolymers. Intensive research is currently being carried out related to these binders. Despite some successes and promising approaches, however, it must also be noted that no binder has yet been developed or is under development which, in terms of its technical properties, is equivalent to the product Portland cement clinker.

Approach 3 (see (Figure 4)) is characterized by the fact that a large proportion of the cement is replaced by finely ground inert aggregates. The underlying idea is that these aggregates form the necessary fines in the concrete mix to ensure the cohesion and the processing of a concrete mix, and also contribute to the concrete strength, which is, however, mainly provided by the remaining Portland cement clinker. This approach, which dispenses completely with the use of SCM, is further described below.

Approach 4 indicated in (Figure 4) is a combination of approaches 1 to 3 with the additional use of recycled aggregates for concrete production. The amount of recycled aggregates may cover a large part of the total aggregates.

An alternative to these four approaches is the CO2 avoidance strategy by carbon capture and storage (CCS) or carbon capture and use (CCU) concepts being under development in some countries. These concepts allow the conventional production of PC as the associated CO2 emissions are captured by applying available technologies. Although this is a promising approach, it must be noted that there are numerous technical, economic and social problems associated with it. It is very unlikely that a sufficiently large volume of PC may be produced by applying these technologies, in particular not until 2045, when the zero CO2 emission target should be reached in Europe.

Approach 1 is mainly used by the cement industry to significantly reduce the mass proportion of Portland cement clinker in the binder for concrete. As a result, there is a very wide range of more environmentally friendly, standardized binders/cements for concrete on the market today. Approaches 2 and 3 are the focus of the current research. This research is entering new areas that are not the case with the cement industry approaches, as it has to stay within the framework of established regulations and codes with its modified binders to be able to serve the needs of the market.

3.2 Rock powder approach

As already mentioned above, approach 3 was developed and scientifically investigated in more detail by (Müller et al, 2016) (Müller et al., 2019). One of the main reasons for this was the positive result of preliminary investigations, which showed that it is possible in principle to reduce the cement content of concrete from over 300 kg/m³ to values of around 100 kg/m³ if the missing cement quantity is replaced by aggregate powders without losing any of the concrete‘s essential properties. A further positive aspect is that rock powders are available for the time being or may be easily produced in large amounts anywhere in the world.

However, this change in the composition of concrete, i.e. the replacement of cement with rock powders is associated with considerable complications. Elaborated particle packing density model approaches must be used to determine the composition of the fines properly. To ensure sufficient workability – the water content of the concrete must be drastically reduced to prevent the water-cement ratio from increasing too much when the cement content reduces – extensive preliminary tests with various superplasticizers proved necessary. Note that superplasticisers have been chemically designed to work with cement particles and not with fine aggregate particles which have different molecular surface properties.

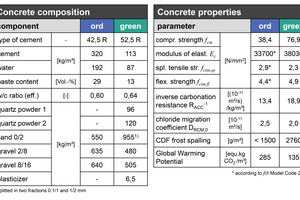

(Figure 5) summarizes the important results of the extensive investigations given by (Müller et al, 2019). It shows the composition (above) of a standard structural concrete (“ord”) and a green concrete (“green”) produced according to approach 3. The lower part of (Figure 5) shows the concrete properties determined in each case. While the strength parameters and the stiffness of the green concrete are even better compared to ordinary concrete, the lower resistance to carbonation and the insufficient frost resistance in particular are deficits. However, it appears that these disadvantages can also be compensated to a large extent by further developments. On the other hand, such green concrete could already be used wherever no frost attack is given. Its GWP is reduced to a value of approx. 50 % compared to that of ordinary concrete (here GWP considers all materials and processes).

A rather particular aspect has to be considered when comparing the composition and the properties of conventional and green concrete produced by the rock powder approach. While the water-cement ratio increases from 0.60 to 0.64, the compressive strength increases from 38.4 to 76.9 MPa as well (see (Figure 5)). This is in contrast to Abram’s well-established law, which states that with increasing water-cement ratio the compressive strength is decreasing. This means that green rock powder-type concretes behave differently than normal concretes, and that well-established relations for normal concretes are not necessarily valid for these types of green concrete.

3.3 Problems associated with sustainable con-

cretes

The positive development of hydraulic binders for concrete with regard to environmental issues due to the increasing substitution of Portland cement clinker is accompanied by a certain disadvantage resulting from the novelty or the lack of experience with these products, respectively. Thus, for classical concrete, whose binder consists essentially of Portland cement clinker and/or granulated blast furnace slag, a very large number of scientific studies are available with regard to a wide variety of material properties, as well as extensive long-term observations and practical experience. These findings have been reflected in material models and design approaches available to the design engineer. Since this is not the case for concretes with new binders, the necessary performance tests to ensure safety and durability are of great importance when building with these new types of concretes.

4. Structural design for sustainability

The Concrete Sustainability Potential as defined by (Equation 1), see Part 1, is a useful tool for making comparative considerations when selecting or specifying a concrete in advance of a construction project. This tool makes it possible to identify a specific concrete with a high sustainability potential that also meets the required technical specifications. However, in order to be able to carry out an engineering design of concrete for sustainability, (Equation 1) must be reformulated for various reasons. This also applies to the case that (Equation 1) is used for the design of components, which is possible in principle as well.

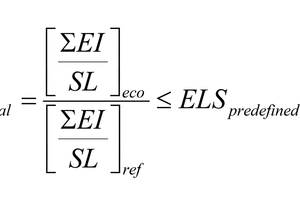

In design, target values have to be related to an upper or a lower limit. Hence, the inverse of the Concrete Sustainability Potential shall be considered. Further, it is very difficult to give limiting values for a property like sustainability, as it is not based on a defined physical dimension like strength or energy. Hence, relative values should be determined, i.e. a calculated current value (“eco”) has to be divided by a reference value (“ref”) so that as a consequence the dimensions are cancelled.

Further, as the concrete strength is the basis for the design of a member, and is calculated from the requirements regarding the load-bearing capacity, it is kept constant both for “eco” and “ref” and thus cancelled in the design equation for sustainability, see (Equation 2).

Taking the aforementioned considerations into account, the general format for verification of concrete environmental performance is proposed with (Equation 2), which defines a limit state, see (fib Model Code, 2023):

ELScal is the calculated concrete environmental performance limit state, ELSpredefined is the limit value that defines the ELS criteria, EI is the environmental impact of concrete and concrete production and SL is the service lifetime.

The index ref indicates the value calculated for a reference concrete. The index eco indicates the value calculated for a concrete for which an optimization has been carried out in such a way that the predefined limit state criterion (ELSpredefined) is fulfilled.

For practical application, (Equation 2) can also be simplified, for example by focusing the limit state consideration exclusively on the CO2-eq emission. In such case, ∑EI = CO2-eq mass per cubic metre [kg/m³] of concrete and SL = 1.0. For more details, see (Haist et al., 2022a); (Haist et al., 2022b); (DAfStb, 2024); (fib Bulletin NN, 2026).

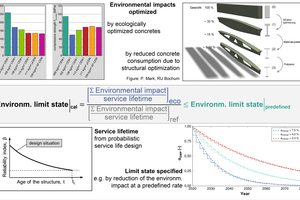

(Figure 6) shows an example of dimensioning according to (Equation 2). First, different concretes must be compared with each other in terms of their sustainability potential given on the y-axis, see (Figure 6), diagram top left. As a result, a specific ecologically optimized concrete can be selected. A further step is to optimize the structural component in terms of maximizing the load-bearing capacity while minimizing the concrete consumption (see (Figure 6), diagram top right). Both considerations and optimizations lead to an optimized environmental impact for the finally used structural component.

The next step in this design approach is to consider the service life (see (Figure 6)). Ideally, a probabilistic design for service life is carried out. The diagram at the bottom left in (Figure 6) shows the result of such a design, whereby the reliability index given on the y-axis decreases with increasing time under service. At the end of the defined service life, the given reliability limit state is reached.

In the last step of design, the limit state for sustainability must be defined. Due to the structure of the design equation, this limit state can be expressed by any number between 0 and 1. Since with regard to the reduction of CO2 emissions, the desirable limit state of zero emissions cannot be achieved immediately but rather through a degressive development over time, the assessment can be based on corresponding progressions, taking into account the calendar year. The diagram at the bottom right of (Figure 6) shows the curves for three different annual reduction rates for CO2 emissions.

This concept for sustainability assessment and design presented here is innovative and new. It can be considered as a basis and framework, and as a starting point for further developments. So far, there is no practical experience in the application of this concept. It is to be expected that the application of this concept in the practice of concrete construction will certainly lead to further improvements in the coming years.

5 Concluding considerations

The concrete construction industry faces significant challenges, which primarily consist of reducing the CO₂ footprint of concrete construction without negatively influencing the technical performance and the superior durability of the produced structures as well as the high economic efficiency of the entire construction method. Even though environmentally optimized concretes are readily available today and techniques to produce much slimmer and mass reduced structures have been proposed, these techniques are rarely implemented in everyday construction as suitable incentives and the necessary knowledge are lacking.

Nevertheless, it is the designer who plays the decisive role in the way to an efficient reduction of the GWP and the protection of the global climate. The design aids proposed with (Equation 1) and (Equation 2) are initial approaches, still to be further developed, for demonstrating the sustainability of materials and components. However, such proofs will only find their way into practice when a core problem that still exists today is overcome. This is because nearly all measures that lead to a significant improvement in sustainability are ultimately still associated with higher costs. As long as this does not change, the cost pressure in the competitive economic environment means that the desired, major progress will fail to materialize.

Ultimately, this deficit can only be eliminated by enforcing sustainable measurement with normative specifications. Since the CO2 emissions associated with the production of concrete components can be calculated with the tools available today, one concept could be, for example, to price the CO2 emissions, as is currently already the case with emissions trading. It will be interesting to see what solution politicians come up with in this regard. The necessary tools have already been provided by the research community.