Rheological behavior and CO2 footprint of cements binder exhibiting ultra-low clinker content

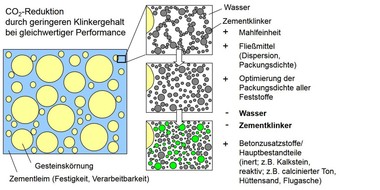

In order to reduce the CO2 footprint of cement it is necessary to decrease the clinker content significantly, i.e. well below 50 %. To probe into such systems, the use of alternative raw materials like GGBFS (Ground Granulated Blast Furnace Slag) in the mixtures has to be considered; slag content can vary and its introduction allows to strongly decrease clinker content. Studies have shown that GGBFS could potentially reduce the carbon footprint in a typical concrete mix design by ~ 22 %.

In our work, we have identified the suitable PCE superplasticizers for cement composite exhibiting ultra-low clinker content. The results suggest that for such binders of extremely low clinker content fundamentally different PCE structures are required, and that the behavior of PCEs established on OPC cannot simply be applied to those slag dominated binders. At the same time, those novel binders stand out because of their extremely low CO2 footprint. A rough assessment produces the values

as follows (kg CO2-equ./to binder) : OPC 825; slag 100; blended cement (60:40 GGBS: clinker) 390; blended cement (70 GGBS:30 clinker) 320; and finally blended cement (85 GGBS:15 OPC) 210. This suggests that by using such ecologically optimized binders a massive reduction in CO2 emission of up to 75 % is possible.

Apart from the drastically lower CO2 footprint of the novel eco binder also the CO2 emission associated with the use of the PCE admixture needs to be considered. For PCEs, depending on their individual structural composition, the values vary between 3.000 and 5.000 kg CO2-equ./to PCE. Bearing in mind that PCEs typically are applied at dosages well below 1 % by weight of binder, their CO2 contribution amounts to ~ 10 – 25 kg CO2 equ./to binder. Here, an advantage of the slag rich binder is that it generally requires up to 50 % lower PCE dosages to achieve comparable workability as in OPC.

The investigations demonstrate that “green cements” of ultra-low CO2 footprint (as low as 200 kg CO2-eqn./to) are already possible.

Co-Authors / Mitautoren:

Dr. Laurent Frouin, Dr. Mohend Chaouche, Dr. Roberta Alfani