Design approaches for sustainable concrete mixes and structural components (P. 1)

Changes in the current use of concrete materials and design approaches are mandatory in order to comply with the requirements imposed on future sustainable concrete structures. Before this background, the article indicates the design of sustainable concrete mixes (green concretes or eco-concretes) – read here Part 1.

Changes in the current use of concrete materials and design approaches are mandatory in order to comply with the requirements imposed on future sustainable concrete structures. Before this background, the article indicates the design of sustainable concrete mixes (green concretes or eco-concretes) and the structural components made from them. Such concretes are characterized by a pronouncedly reduced CO2 footprint compared to conventional structural concretes made purely with Ordinary Portland Cement (OPC).

After an introduction to the sustainability problems of today‘s structural concretes, the basic approaches for the development of sustainable concrete are presented. The specific parameter Concrete Sustainability Potential is introduced, which combines the main effecting parameters such as environmental impact, service life (durability) and performance (strength). An overview of possibilities available today for producing sustainable concrete mixtures is given. For good reasons, emphasis is placed on such sustainable concretes, in which a large proportion of the OPC is replaced by rock powders.

Finally, a new and innovative relationship for sustainability design is introduced. This concept is equally applicable to concrete as a material and to components made from it. The article concludes with considerations on the implementation of this new concept in practice.

1 Introduction and overview

Today it is well known that the production of concrete is associated with high CO2 emissions which result mainly from cement manufacturing. However, it was not until the turn of the millennium when that awareness was raised that the production of cement is one of the most energy-intensive and CO2-intensive industries in the world, surpassed today only by energy production through the burning of fossil fuels, the traffic and the steel production. It is estimated that the cement industry is currently responsible for about 7-8 % of the global man-made CO2 emissions.

These emissions have to be significantly reduced, as a contribution of the concrete industry, so that the international agreement to limit global warming to a maximum of 1.5 degrees Celsius above pre-industrial level can be reached. This target was set in the Paris Agreement of 2015 to prevent the worst effects of climate change. It is therefore not surprising that many strategies have been developed, particularly in the past decade, to significantly reduce the CO2 footprint associated with concrete construction.

When thinking of a solution to this sustainability problem, three basic ideas can be identified. The first and very simple solution could be to strive for a tremendous reduction of the use of concrete, e.g. by shifting away from concrete to other building materials such as timber. However, in many cases this is impossible, as for many applications, no alternatives to concrete are available. Further, worldwide economic success is very much linked to an efficient infrastructure, thus relying on concrete. As a consequence, concrete became by far the most important building material of the modern industrial age. Its decisive advantages - comparatively high strength and durability associated with high availability in huge quantities and cost-effective production anywhere in the world - are up to nowadays not even remotely matched by any other building material. Concrete has made possible the economic development of the industrial nations over the last 100 years. With an annual production volume of currently approx. 8 billion m³ of concrete, economic development worldwide would not be possible without it.

The second solution consisting of completely replacing cement with another binding agent cannot be implemented either. To date, there is no alternative binder that could even come close to the positive properties of Portland cement clinker. And, if one considers the huge quantities of suitable base materials for binder production that have to be available all over the world, this solution is also ruled out from the outset.

The third solution consists of retaining conventional cement production but capturing the CO2 emissions. The technology of capturing CO2 has made significant progress in the last years, and currently, pioneering pilot projects are testing the scalability of the technique. If this technology proves successful, it will probably last decades before every cement plant in the world has been converted accordingly. Even more important is the fact, that carbon capture and storage technology (CCS) requires adequate storing facilities. Here progress unfortunately is often hindered by public acceptance problems. Further, it must also be accepted that the price of cement will rise significantly.

In view of the three alternatives for avoiding CO2 emissions in concrete production described above, which cannot be implemented for various reasons, the only remaining option for the coming years is to reduce CO2 emissions by making suitable changes to the composition of cement and concrete.

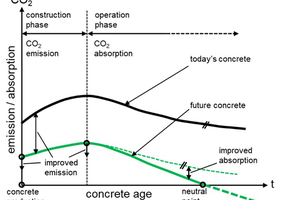

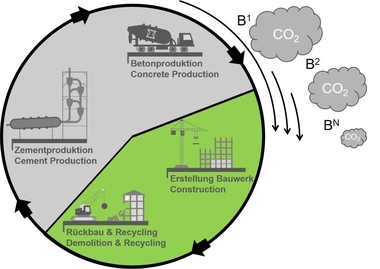

Two different or complementary strategies, respectively, can be established along the service life of a concrete structure. They aim (i) to reduce CO2 emissions during the construction phase including concrete production, and (ii) to maximise CO2 absorption during the operation phase. Both targets can be achieved by an appropriate adaption of the composition of the concrete and by additional measures during production, placing and curing.

(Figure 1) illustrates the development of CO2 emission and CO2 absorption over time as they are today and as they should be in the future. With the help of suitable developments, the overall CO2 balance tends towards zero and can ideally even become negative in the future after a long service life of a concrete structure. In order to drive forward corresponding developments, the German Research Foundation has been funding the Priority Programme SPP 2436 entitled Net-Zero Concrete since summer 2024 (Deutsche Forschungsgemeinschaft DFG, 2024).

The article at hand focuses on the possibilities of reducing CO2 emissions in the construction phase by optimising the composition of the concrete. This can be achieved by various strategies, which are discussed in this article.

For comparative and evaluative considerations, the introduction of the Concrete Sustainability Potential is an important tool as it combines the governing para-meters of environmental impact, service life (durability) and performance (strength). Further, an overview of the possibilities available today for producing sustainable concrete mixtures having an improved CO2 footprint is given. Hereby, emphasis is placed on such eco-concretes for which a large proportion of the cement is replaced by rock powders.

Finally, a new and innovative relationship for sustainability design is introduced. This concept is equally applicable to concrete as a material and to structural components made from it.

2 The sustainability potential

From the facts indicated in the previous chapter, it becomes evident that at first sight the concrete composition must be fundamentally changed. In particular, the content of Portland cement clinker, which is inflicted with very high CO2 emissions, must be reduced or must be substituted as far as possible by more environmentally friendly binders. However, when evaluating the sustainability of concrete, singularly addressing the CO2 emissions falls short. For example, if one single high CO2 emission is associated with the production of high-quality concrete that may withstand all critical exposures for many decades without repair or replacement, then the initial adverse emission has to be evaluated differently. This means that high performance and durability are required from the building material itself in the case of structures, which, however, cannot be guaranteed in principle by ecologically optimized concrete. Therefore, the parameters of performance and service life must be considered equally with the environmental impact in a balance sheet related to sustainability. Taking these considerations into account, the Concrete Sustainability Potential (CSP) was introduced as defined by (Equation 1), see (Müller et al, 2016); (fib Model Code, 2023):

Herein, fck is the characteristic strength of the concrete in [MPa] representing the possible performance of the material, tSL is the potential service life of the concrete under the specific environmental actions to be expected in the lifetime of the building member in years [a], and GWP is the environmental impact associated with the production of the concrete including all raw materials expressed by the lead parameter Global Warming Potential (GWP) in eq. kg CO2; for further details see (fib Model Code, 2023).

(Equation 1) represents a simple tool to quantify the advantages and disadvantages of a specific concrete type regarding its potential as a sustainable material. The exploitation of this potential during the design and construction process depends on the designer and user of the building or structure. It should be noted that (Equation 1) may also be applied to structural components.

According to (Equation 1), three basic approaches to sustainable use of concrete exist: The first is the optimization of the composition of the concrete regarding its environmental impact while maintaining an equal or better performance and service life; the second is the improvement of the concrete’s performance at equal environmental impact and service life; the third is the optimization of the service life of the building material and the building structure at equal environmental impact and performance. A combination of the above-mentioned approaches appears reasonable.

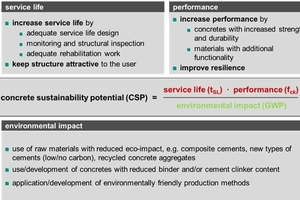

Figure 2 provides an overview of various methods for maximizing the service life and the performance of concrete and concrete structures and for minimizing environmental influences and thus improving sustainability:

In terms of service life, structural monitoring and structural inspection as well as applying sustainable repair work are particularly suitable methods for increasing the service life of a structure. In this way, the building also retains its attractiveness for the user. The service life assessment at the stage of design is also of great importance. If a structure is only used for a short period, for example in industrial construction, significantly lower quality of concrete is acceptable than for structures which are used over long periods, as is the case with structures of great economic importance (tunnels, bridges, dams). Note that currently the higher the quality of concrete the higher the associated CO2 emissions.

In terms of concrete performance, higher strength results in lower material consumption for the same load-bearing capacity of components. Further, an increase in durability is advantageous because the service life of the structure is extended and early repair is avoided. Improved overall resilience also leads to lower CO2 emissions when using concrete.

There are essentially three different ways to reduce the environmental impact by reducing CO2 emissions during concrete production. Firstly, concrete raw materials should be used that have a lower CO2 footprint from the outset. It is also beneficial to use recycled concrete as aggregate. Furthermore, efforts must be made to use as little Portland cement clinker as possible. Finally, the overall CO2 emissions can also be reduced by optimizing the production of concrete and its transport.

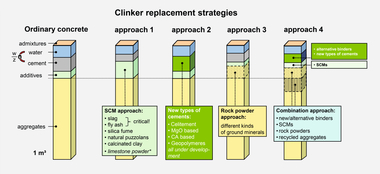

Related to the environmental impact, i.e. the use of raw materials with reduced eco-impact, e.g. composite cement, new types of cement (low/no carbon footprint), recycled concrete aggregates and the use/development of concretes with reduced binder and/or cement clinker content, chapter 3 of this paper indicates further details.

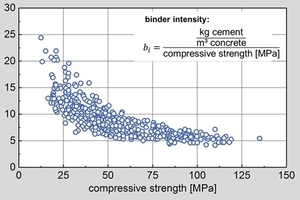

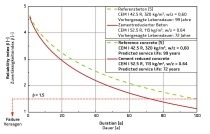

As the use of Portland cement is indispensable for producing structural concrete today, the question arises as to what the most efficient way is when this binder is applied in view of minimizing the environmental impact. In this context, a concrete data evaluation by Damineli (Damineli et al, 2010) is very revealing. They have defined a so-called binder intensity, and have plotted this binder intensity over the compressive strength (see Figure 3).

The decreasing binder intensity with increasing compressive strength, as may be depicted in (Figure 3), indicates that the use of Portland cement is the more efficient (sustainable), the higher the strength is. This is more pronounced as for higher strength concrete the cross-section of members may be reduced, i.e. a reduction in mass consumption is achieved at a given load-bearing capacity.

Figure 3 also indicates that for normal and low-strength concrete the amount of cement used for these concretes is not necessary for the reason of strength, however, it is beneficial for workability and durability reasons. This means that a large amount of cement may be saved if workability and durability are guaranteed by other measures. This would be very efficient in view of sustainability as roughly 90 % of all concretes used in practice have a compressive strength between 20 and 50 MPa.

From Figure 3 the general conclusion may be drawn that either the reduction of the binder content of ordinary strength concrete or the use of high strength concrete lead to a sustainable use of concrete. The concept of reducing the binder content for ordinary structural concrete while keeping its advantageous technical properties is further analysed in the subsequent chapter 3 of this paper (Part 2).