Solutions that have inspired for 90 years

Cable cars that span the width of an ocean, mega high-bay ware-houses that can accommodate up to 100,000 t of aluminum coils, and the most advanced, state-of-the-art precast concrete part plants in the world are just some of the many projects that underscore the relentless innovative spirit lived out every day at Vollert. In 2015, the company will celebrate its 90th anniversary and plans to invest over four million euros to take on additional challenges and continue growing.

Inspired moments have been more the rule than the exception for the engineering specialists at Vollert in the last few decades and have practically become part of the firm’s core business offering. A general contractor that serves customers on all continents, Vollert designs and manufactures fully automated precast concrete plants, state-of-the-art intralogistics systems for the aluminum and metal industry, and the world’s leading shunting and loading systems that handle product in refineries, the chemical industry, and in other applications.

Production circuits for the precast industry

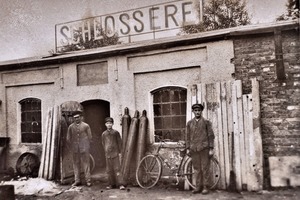

What began as a small locksmith’s shop in 1925 quickly evolved into a specialist in automation systems that caters to the requirements of heavy-duty operations. In the 1930s, the first vineyard cable cars developed by Vollert became an international bestseller as orders were received from the Americas all the way to Hungary. Later on, this design served as a springboard for constructing bucket and cableway conveyors that were used to haul payloads of up to 20 t in limestone and sandstone quarries. In the 1960s, Vollert developed a cableway in Venezuela that held the world’s record for the longest distance between support pillars at 1 km.

By leveraging their keen sense of mechanical understanding and technical know-how, the engineers always thought outside the box to advance automation in new industries as well. The principle of the cable car was applied to floor-bound rope conveyors in the 1950s and revolutionized the timber and ceramic industries, among other sectors. Sawmills, brickyards, and porcelain manufacturers such as Villeroy & Boch then seized the opportunity by converting to production circuits. Later on, Vollert was the first provider to introduce this technology to the precast concrete industry.

Today, the technology leader exports trend-setting engineering concepts for precast concrete plants all the way to New Caledonia in the South Pacific.

Solutions that move entire industries

The family enterprise, originally founded by Hermann Vollert, continued to grow and expand into an international general contractor, with subsidiaries in Asia, Russia, and South America. The company is now managed by the third generation of the family, and business couldn’t be any better. “Our plant and machine solutions have a track record of taking different industry sectors to new levels – not to mention ourselves”, explains Managing Director Hans-Jörg Vollert, the grandson of the company’s founder. A pioneer and pacesetter, Vollert has always prided itself in paving the way to launching new technologies. Back in 1974, engineers introduced the first fully automatic shunting robot for freight wagons that operated using emissions-free, battery-operated drives. The design has since been advanced further to take the shape of the first “GreenTech robot”, which features a hybrid drive system and was unveiled at the 2014 InnoTrans international trade fair.

Oftentimes, the best solution boils down to small details. Patented pendulum suspensions in compaction stations, for example, reduce the amount of cement required in precast plants, while innovative safety solutions developed in house for rack feeders and cranes help to prevent cable breakage when overloads are experienced.

Customers in over 80 countries

Vollert is now an international player and the specialist to go to for realizing intelligent material flow and storage systems for the metal and aluminum industry. The company is also a leading technology and innovation driver in the precast concrete industry as it has already erected over 350 production plants for manufacturers of the precast elements. The customer base circles the globe, with customers in 80 countries, and includes such well-known organizations as Daimler, Liebherr, Hydro, Aleris, APT, SSAB, Terex, Esso, BASF, Strabag, Kemmler, and Laing O’Rourke.

At the BMW Welt facility in Munich, a fully automated high-bay warehouse from Vollert provides a continuous supply of new vehicles, while concrete railway sleepers using Vollert-designed equipment are being installed in the Gotthard Tunnel and the world’s largest high-bay warehouses for aluminum coils are currently under construction in China. Vollert engineers also develop overhead painting booths for large excavator and crane parts weighing up to 50 t and automatic cranes with a curb weight of no fewer than 260 t.

Investing in a future ”Made in Germany”

Wherever heavy loads need to be moved, stored, or transported fully automatically, the engineers at Vollert can find the right solution for the job. “Nothing is impossible, and it is always beneficial to think about new and better ways of doing things. At the same time, we also strive to develop a cost-effective and efficient solution”, says Hans-Jörg Vollert. “Although we are currently in a very good position with respect to the metal, aluminum, and precast industries, who knows what is to come. It is exactly this unknown element, however, that makes our products and solutions exciting.”

All the more reason for Vollert to continue investing heavily on into the company’s anniversary year. Plans to this end include a new drilling center, a larger outdoor storage area, as well as new offices and spacious visitor areas as Vollert pursues developing and manufacturing high-quality plants in Germany despite maintaining its own subsidiaries in Russia, South America, India, and China. “After all, the ‘Made in Germany’ label is an important measure of quality for ourselves and many of our customers, and we want to continue building on our know-how and experience on home turf”, accentuates Vollert.