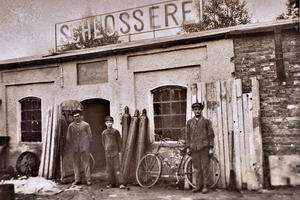

Vollert has been shaping the future – for 100 years

Vollert celebrates its 100th anniversary in 2025 - and continues to shape the future. The theme of the anniversary year is ‚Empowering Tomorrow‘ and the heavy-duty experts have no shortage of ideas and new concepts for automating a wide range of industries.

With new technological approaches, concepts and ideas, the longestablished company Vollert sees itself time and again as a trendsetter in the industry and always has the future challenges of its customers in mind: Making material flows more efficient with new intralogistics concepts, creating affordable living space for millions of people with sustainable construction systems or significantly improving the CO2 footprint with battery-powered, emission-free shunting technology. „Today, as in the past, we don‘t know what will happen in five years‘ time - that‘s exciting. We are always open to new ideas, think outside the box and are grateful for the trust our customers place in us. Because with every new challenge, we work together to develop sustainable solutions for the coming decades,“ says Hans-Jörg Vollert, CEO in the third generation of the family business, describing the range of tasks. „Automation, integral processes and digitalization are megatrends that will continue to drive the economy forward in the future, for example in the areas of mobility and transport.“

What moves Vollert in the future

Vollert is well equipped for this with its heavy-duty intralogistics solutions: The growing lack of space and the ever-increasing speed of supply chains require new solutions. New concepts therefore include the development of automated truck parking garages - so-called truck towers - and container high-bay warehouses. These not only reduce space requirements, but also offer significant advantages in terms of speed thanks to short distances. For Logan Aluminum, the largest tinplate plant in North America, Vollert is currently building a comprehensive material flow and storage system in the USA to supply and discharge the hot and cold rolling areas.

The central element is a 130-metre-long high-bay warehouse, which is operated by a 42-metre-high stacker crane - Vollert‘s largest of its kind to date. Despite the high payload of 30 tons, 36 movements of the storage and retrieval machine and thus 18 storage and retrieval operations per hour are possible in combination with the entire conveyor technology. Active individual station cooling in the high-bay warehouse is also provided for uniform and rapid cooling of the coils, which can reach temperatures of up to 360 °C. „We don‘t just sell machines, we develop new solutions together with our customers - that‘s what Vollert is all about,“ explains Hans-Jörg Vollert.

Sustainability determines innovation

This also applies to the efficient shunting of unit loads and bulk goods. Vollert supplied the first battery-powered shunting robots to Holderbank Zement in Switzerland back in 1974. Today, the long-established company has a versatile shunting portfolio for a wide range of applications. E-models or hybrid variants are now playing an increasingly important role – even when loading freight trains weighing up to 6,000 tons. The innovative Vlex road-rail vehicle from Vollert, on the other hand, offers a flexible, low-noise and emission-free alternative for internal transport of up to 600 tons, both on and off the rails. Shunting systems such as the Vlex can also be found in precast concrete factories. Vollert has also been one of the technology leaders in plant engineering here since the 1970s. Today, sustainable building systems are leading the way and new material-optimized construction concepts are in demand. Specifically, it is important to use limited raw materials efficiently and to provide modern living space in accordance with the latest energy guidelines and building standards, for example through resource-saving timber hybrid construction. This is also changing the manufacturing processes in the precast concrete plant, for which Vollert offers new solutions. A plant concept for the serial production of room modules was recently implemented with the still young French construction company Muance. These consist of an intelligent combination of lightweight concrete and plant fibers, which not only reduces CO2-emissions by up to 60%. The Motus construction system developed by Vollert also focuses on reducing CO2-emissions.

For Hans-Jörg Vollert, these are decisive steps for the coming years: „Together with our customers and partners, we are constantly finding new ways to drive technological progress forward - with innovative solutions and first-class engineering skills. Actively shaping the future and making tomorrow better - that is our understanding of ‚empowering tomorrow‘ and we are already looking forward to it today.“