New assessment of horizontal fresh concrete pressure

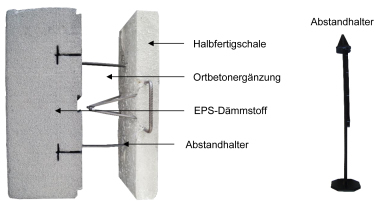

In reinforced-concrete construction, semi-precast elements particularly ensure high cost efficiency, because they enable a faster construction progress while maintaining strict quality requirements. An example is precast element walls with integrated thermal insulation material. For these components, only the outer concrete shells are manufactured in the precast plant. The load bearing final cross-section is installed only at the construction site by subsequent placement of in-situ concrete. The pressure generated during casting the fresh concrete must be absorbed by the connection devices...