Advantages thanks to thermal insulation as outer shell

Building construction in large cities and metropolitan areas is very expensive. Hence, every centimeter of space gained is important for architects, developers and building societies. While they have to meet high requirements on thermal and sound protection. But how can they manage this balancing act between the slenderest construction, on the one hand, and insulation free of thermal bridges, on the other hand? The patented if#3 wall system of if innovative fertigteile GmbH based in Rott-weil, Germany, offers concrete plants an interesting addition to the existing product range and does not require any substantial capital expenditures.

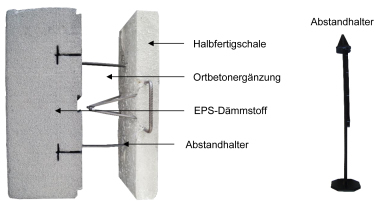

Conventional core-insulated wall elements have a three-layer structure consisting of load-bearing layer, thermal insulation and weather protection layer. Substituting the massive facing layer with the thermal insulation results in a significantly slimmer and lighter structure. In this way, precast factories get a product that is fast to realize, providing them with the possibility to open up new profitable markets.

Production in the precast concrete plant

The if GmbH company delivers the insulation (outer shell) as a precast element to the precast factory; it comes complete with spacers and mounting parts for reinforcement as well as all encased recesses in accordance with the project specification. The lightweight external insulation layer can be transported by means of a forklift truck or by crane to the place of installation on site. There, the reinforcement is fixed to the insulation element. The mounting rails are already provided for this purpose.

Reinforcement of 23 kg/m² was already applied in practice for a project in the Rhine Rift Valley (seismic zone 3). To fix the reinforcement to the thermal insulation has the advantage that no resistance occurs in the concrete shell and the used spacers of the system can freely immerge. In the next step, the reinforcement and spacers are inserted in the insulation element by means of a crane or a turning table. The simple and safe installation process ensures remarkable time savings and an increase in throughput of the concrete plant. The weight advantage of the finished wall element amounts to at least more than 3 tons based on a surface area of 6 m x 3 m, while considerably reducing the transport costs. In addition, the site crane can be used for positioning on the construction site.

Outer shell withstands fresh concrete pressure and vibration

„We have used spacers to connect the thermal insulation of the „if“ wall element to the concrete shell for absorbing the fresh concrete pressure on the construction site. The spacers consist of the material polypropylene and are anchored in the thermal insulation by means of an undercut“, states the general manager of if, Nikolaus Günthner, explaining the patented system. „Concrete is poured and vibrated as for any other precast concrete element“, Günthner adds, being satisfied with his development.

Of course, a new wall system requires thorough testing. The respective tests and the verifications needed have been carried out at the Institute of Concrete Structures and Structural Engineering at the TU Kaiserslautern headed by Prof. Dr.-Ing. Matthias Pahn (also see BFT 08/2018, page 32 ff.: „Load-bearing behavior of wall elements with formwork anchors integrated in the insulation material“), they also prove the functional capacity.

Insulation materials, thicknesses and areas of application

EPS as finished outer shell can be delivered as standard, XPS or PUR are available as options. For this purpose, the insulation elements are cut out of large blocks, being joined together up to the exact wall size with the aid of Phonotherm insulation grooves. The scope of supply includes system spacers and fastening as well as transport rails just as mounting parts for the required secondary and structural reinforcement. EPS 032, for example, allows insulation thicknesses starting from 12 cm. The if#2 wall system can be used from the basement up to the top floor.

Market acceptance and pricing

Using the if#2 wall system in building construction pays off: Floor space of more than 47 m² is gained if, for example, the facing layer is eliminated in case of a multi-family house with a GFA of 2,000 m². This means excess profits of 160,000 up to 250,000 Euros for developers in Berlin, Hamburg, Stuttgart, or Munich. Surely, a striking argument in sales and price discussions. Another advantage is the elimination of interior plaster: Hence, moisture is not carried into the building, as this may be possible in case of a monolithic masonry. Potential structural damages can be minimized right from the beginning.

Reference buildings have already been realized in Germany, France, and Switzerland and the first concrete plants have started production in Germany. The precast element can be placed on the market more favorably priced than a conventional double wall construction with core insulation (but does not have to be). Property developers may rather be prepared to pay a little more as they will earn considerably more due to the floor space gained. This also increases the added value of the building.