Free-flowing thermal

insulation

Pourable, sustainable and easy to dispose of - that is how the future insulating material should be. They should, in addition, be classified to fire-resistance A1 without any loss of the thermal insulation value. In this regard, the pourable Geo-lyth mineral foam convinces in every aspect.

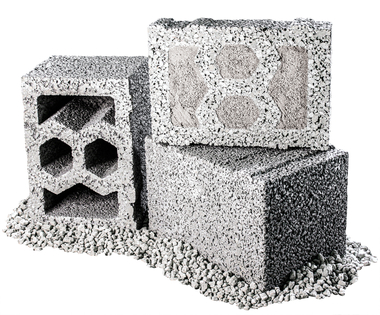

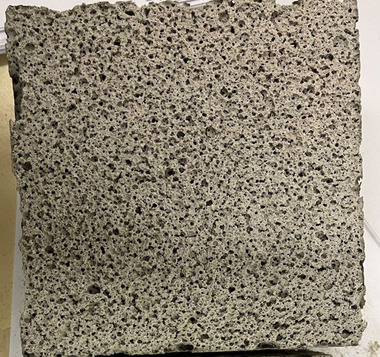

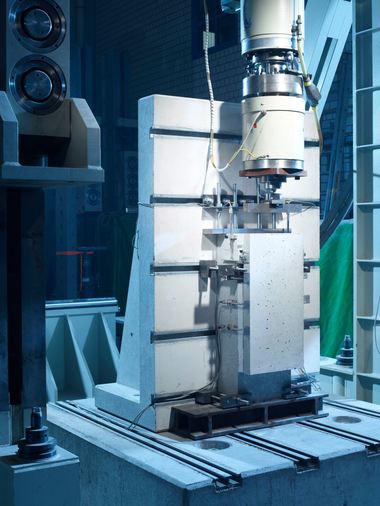

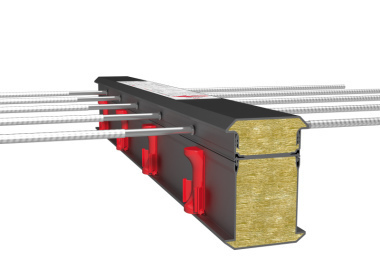

Thermal insulation is the requirement of the future buildings. Geolyth mineral foam offers a new approach. The purely mineral, cementitious material impresses with excellent thermal insulation values (λ = 0.035 W/m2K). It is unique because of its flowability, this means that it can be poured liquidly into bricks or hollow concrete wall panels as an additional insulation. The basic rule in building physics concerning a functioning masonry reads that it should be open to vapor diffusion from the inside to the outside. Geolyth mineral foam demonstrates its strengths also in this respect because it combines an excellent thermal insulation with an outstanding water vapor resistance factor (μ = 2). Therefore, Geolyth mineral foam guarantees a durable, sustainable, functioning masonry that is dry, which is basically the precondition for preventing the formation of mildew.

The basic material of the mineral foam is a purely mineral compound in powder form that has been developed over several years. The product is mixed with water in an especially designed mixer becoming a foam up to a liquid in its fresh state. Because of its pourability it can be cast into any mold or formwork. The mineral foam demonstrates its ecological strength, in particular, when it comes to the disposal of the same: the purely mineral material can be disposed of together with any other mineral building material and even losing volume.

Possible applications for the insulation material are in new construction for bricks and hollow blocks filled with mineral foam as well as in precast concrete construction for sandwich walls combined with mineral foam. Furthermore, the product is recommended for the refurbishment of old buildings. As it is open to vapor diffusion, the innovative mineral foam makes even internal insulation attractive again, which is also due to the fire resistance class A1. Therefore, Geolyth mineral foam is an appropriate alternative as a future building material owing to processing reasons, from an environmental point of view, and above all as building physics is concerned.