A round anniversary approaches – 20 years of setting standards

Attaching a concrete box with wings directly to the reinforcement? Fixing the flush-mounted box in the hole with foam? Cavity wall boxes that can be combined and therefore directly wired? With all these inventions, Primo initially caused a great deal of astonishment that quickly turned into great relief by substantially facilitating electrical installation work. Now, in 2025, this manufacturer of innovative installation material is celebrating its 20th anniversary.

“This system is thought through down to the smallest detail and greatly facilitates work.” With these words, Walter Kurz, Managing Director of Itech Elektro GmbH, describes the products of Primo GmbH. This year, the manufacturer of innovative electrical installation materials, located in Aschau on the Inn River in Germany, is celebrating its 20th anniversary – as a company that has been committed to revolutionizing craftsmanship from the very beginning.

From professionals for professionals

The reason for this lies in the company’s own history: in 1998, company founder Thomas Wintersteiger began his training as an electrician in the family-owned business Elektro Wintersteiger. “During this time, it became clear to me time and again how cumbersome products and methods were. Together with my father, we then developed ideas for making work easier, faster, and yet still of high quality,” he recalls.

For example: Exploratory drilling at a large construction site in Munich resulted in reduction of DM 10,000 in the company’s invoice. After that, his father, Herbert Wintersteiger, developed the cable carrier, millions of which are still being sold to this day. The requirements of the exposed fair-faced concrete look of a museum in Munich led to the invention of the Winged Concrete Box. This method is now indispensable on concrete construction sites and was the first major standard set by Primo.

Award thanks to practical experience

More ideas and products that were initially intended for the company’s own use followed. “But it quickly became clear that our innovations were in demand on the market and that we were able to offer electricians on construction sites significant added value,” explains Thomas Wintersteiger. He then founded Primo GmbH, in 2005, and successfully began marketing the family‘s inventions.

Only two years later, the young company was awarded the Federal Prize for Outstanding Innovative Achievements in the craft sector for its Winged Concrete Box, as well as the Bavarian State Prize for its MultiSocket. For the first time in 16 years, both prizes were thus awarded to one single company. “We were naturally very proud of this, which encouraged us to continue on our path,” says the now 40-year-old Managing Director.

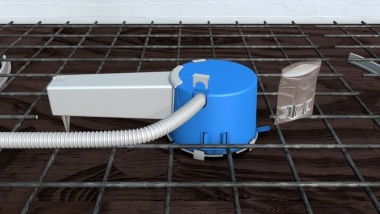

Thermo Box: the original

The major Primo breakthrough followed in 2016, when its Thermo Box was launched on the market. This development eliminated the need for flush-mounted boxes that had to be filled with plaster, which is time-consuming and strenuous. According to the company’s statement, the world’s fastest box system requires only a single spray with the Thermo Foam that has been especially developed by the company to assure a tight fit for all components involved. This method enables, at the same time, provision of a thermal bridge and airtight sound insulation – everything in one single box.

Initially viewed critically, the Thermo Box has by now become firmly established on the market and has set another new standard for electrical installation. “Our objective is to develop solutions that provide the electrician with additional work facilitation. These solutions are designed for multiple applications and save time and money,” as Thomas Wintersteiger describes the corporate philosophy. Customers particularly appreciate the clear practical relevance of the solutions.

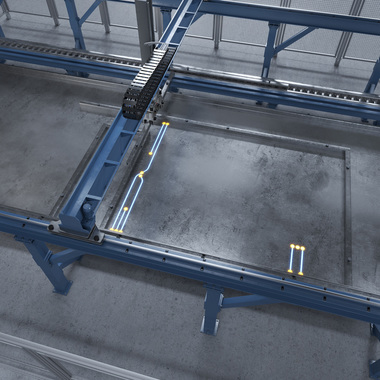

The new dimension of Hollow Wall Boxes

“When using the products it becomes quickly apparent that real thought went into their development,” summarizes Nieky Smits, Plant Manager at Weber Betonwerke.

And Primo remains true to this path to today. In its anniversary year, the Upper Bavarians surprised the market with a completely new series for installation work in dry wall construction. The Hollow Wall Boxes of the Q series, thanks to their diameter of 74 mm, enable fixed combinations and thus direct, airtight wiring. This facilitates and speeds up installation even more than before.

“Feedback has so far been completely positive. We are firmly convinced that these boxes will be true gamechangers in drywall construction and will once more redefine the standard in electrical installation,” says Thomas Wintersteiger.

CONTACT

Fertigteilwerke bei der Primo GmbH

Mario Achatz

Wernher-von-Braun-Straße 2

84544 Aschau am Inn

+49 8638/88559-261