Newly developed precast concrete staircase saves 20 percent in materials

06.08.2025

Figure: Dennert

What lies within often goes unnoticed – and that’s certainly true for concrete staircases. Their structural integrity is typically provided by reinforcement made of steel bars and mesh. This framework is encased in formwork and filled with concrete, either on-site or – in the case of precast stairs – in a controlled factory setting.

Figure: Dennert

What lies within often goes unnoticed – and that’s certainly true for concrete staircases. Their structural integrity is typically provided by reinforcement made of steel bars and mesh. This framework is encased in formwork and filled with concrete, either on-site or – in the case of precast stairs – in a controlled factory setting.

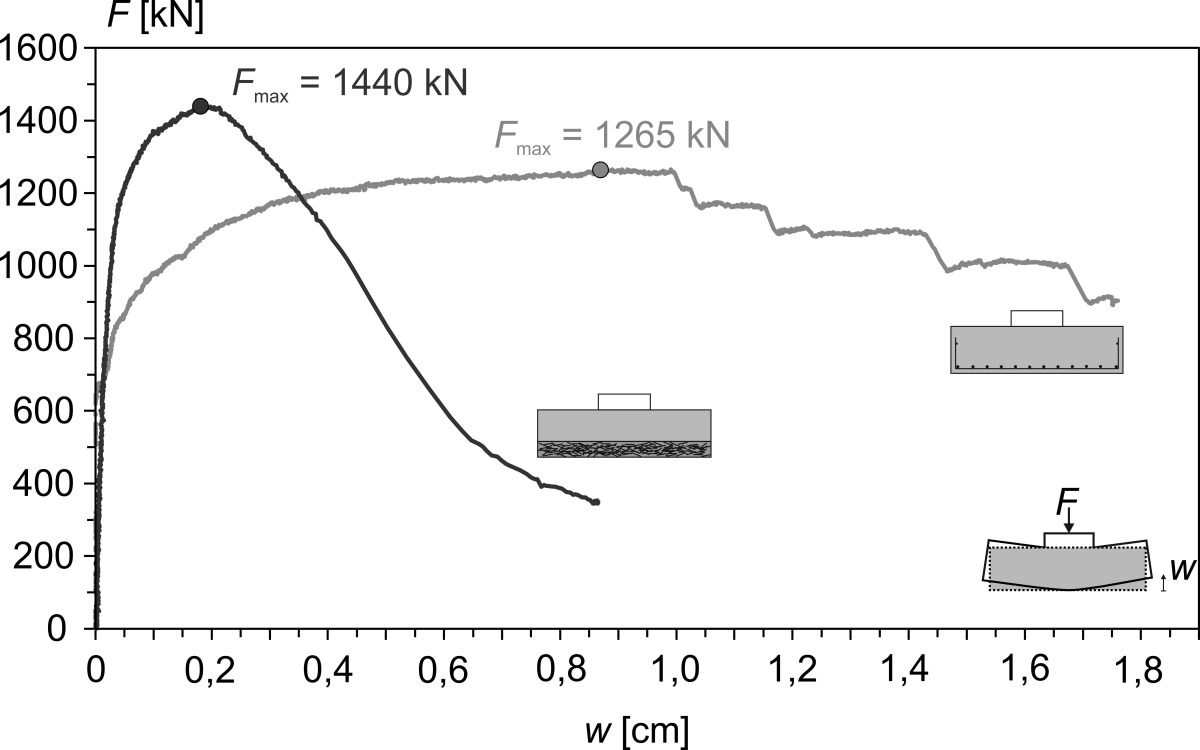

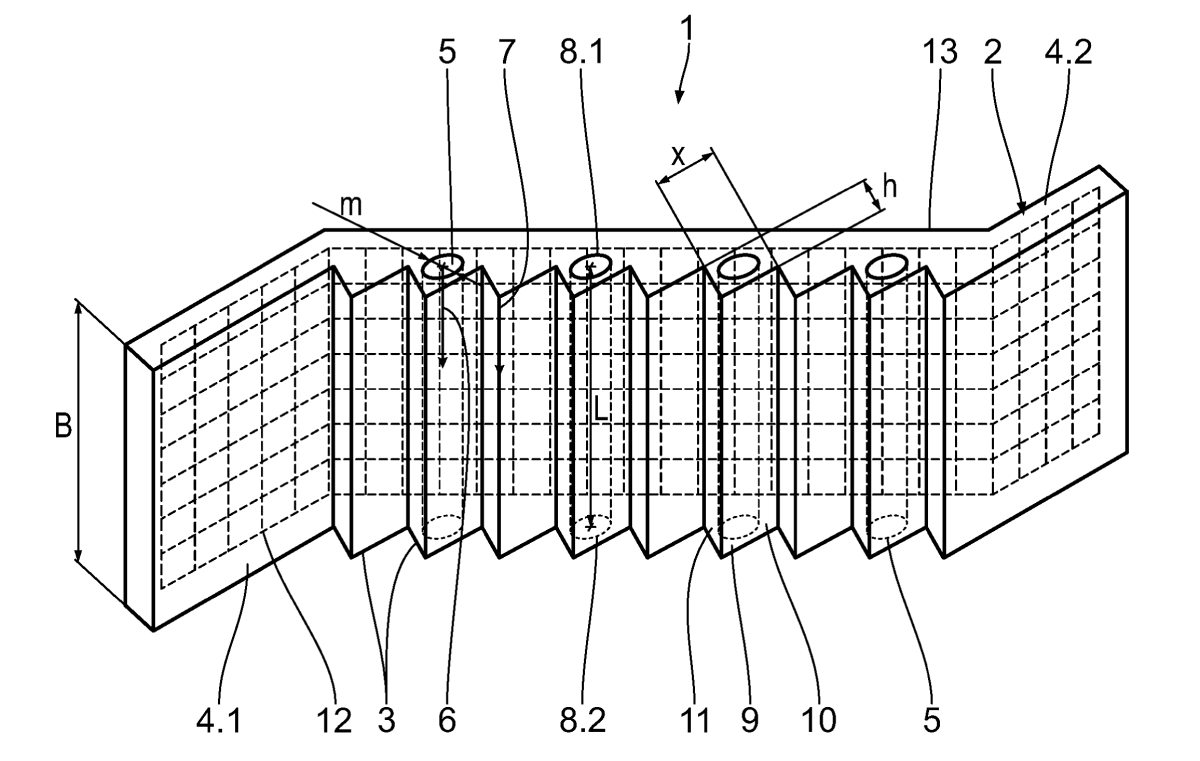

With the newly developed precast staircase "Eco Step", Dennert, in cooperation with Bilstein Steel Fiber GmbH, has taken a significant step toward more sustainable construction, achieving a material reduction of approximately 20 percent. Instead of traditional rebar, the system uses 60 mm-long, high-strength Stabils steel fibers, which are evenly distributed throughout the concrete matrix. Just 25 to 30 kilograms of fibers are required per cubic meter – a significant reduction compared to conventional reinforcement methods.

This steel-fiber concrete mixture delivers exceptionally high strength, enabling the production of "Eco Step" with reduced weight and a slimmer profile. For example, the tread plate thickness is considerably reduced compared to standard designs.

Fast, precise and weather-independent installation

"Eco Step" offers all the advantages of precast concrete construction: The staircase is up to 99 percent factory-made and can be installed on-site immediately – independent of weather and without curing delays. Once mounted, it is fully load-bearing, which significantly accelerates construction progress and ensures scheduling reliability.

The staircase is available in both straight and winder configurations, as well as in custom designs. It is produced at the factory according to the builder’s design requirements. In combination with Dennert’s DX precast floor slabs, construction progresses at remarkable speed: experienced assembly teams can install the slabs within a few hours. As soon as half of the floor surface is in place, the prefabricated staircase can be installed.

According to Dennert, an Environmental Product Declaration (EPD) for "Eco Step" will be available shortly. Further innovations are already in the pipeline: the company plans to launch the "Eco Step+" precast staircase later in 2025. One key feature has already been revealed: integrated cavities under the treads will enable even greater material savings.

CONTACT

Veit Dennert KG

Veit-Dennert-Straße 7

96132 Schlüsselfeld/Germany

+49 9552 71 351