Fibers replace reinforcement – Rapid construction

with fiber-reinforced semi-precast elements

Installing conventional reinforcement is expensive and time-consuming. This process step is eliminated by using steel fiber reinforced concrete. However, in general, fibers are not used as the only structural reinforcement but in combination with conventional reinforcing steel bars because of the usually lower tensile capa-city. In case of very high fiber volume fractions and subsequently consolidating material behavior, steel fiber reinforced concrete is nevertheless able to absorb the structurally required load transfer without additional reinforcement [1]. Then, concrete should be placed in thin layers and in the precast concrete plant.

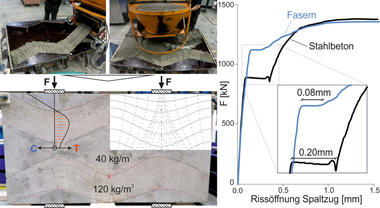

Steel fibers predominantly spread in two directions in slab-type structural elements so that semi-precast elements with supercritical fiber volume fraction of approx. 140 kg/m³ can replace a continuous reinforcing mesh. Semi-precast slabs having a thickness of 10 cm and an axial tensile strength of 3 N/mm² being verified experimentally exhibit the same calculated load-bearing capacity as reinforcement installed crosswise (fyk = 500 N/mm²) of approx. 6 cm²/m per direction.

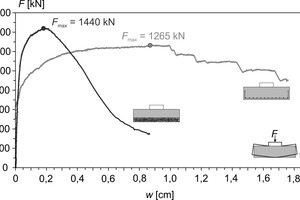

The feasibility is experimentally demonstrated for centrally loaded footings with a geometry of l×b×h=1.1×1.1×0.3 m³. The semi-precast element made of steel fiber reinforced concrete serves as lower bending tensile reinforcement. A footing with reinforcing steel bars of Ø8-9 = 5.6 cm²/m per direction serves as reference. The steel fiber reinforced semi-precast footing achieves a load capacity of 1440 kN, while the reinforced concrete one features an approx. 175 kN lower capacity (Fig.). Verifications of the bending tensile force as well as the crack width control in accordance with DIN EN 1992-1-1 are fulfilled for both versions with nearly the same safety level. Thus, the footing made of semi-precast elements is an alternative to the conventionally reinforced footing. By omitting the production of a reinforcement cage and eliminating the subbase on site, a foundation made of semi-precast elements can be produced much faster, more resource-efficient and less expensive [2].