Windowment – the modular frame for serially prefabricated wall elements

The Windowment modular frame by Beck+Heun enables fast and high-quality window installation. This complete system is suitable for both serial and conventional construction and combines window, insulation, roller shutter box including curtain, and optionally window sills in a single component. Especially in serial precast construction – such as the prefabrication of concrete walls – this modular solution offers clear advantages: the frame can be integrated directly into the formwork before concreting and thus forms a precisely fitting unit within the wall module. Installed in a single work step, the module not only saves time and personnel but also reduces interfaces between trades. Shorter construction times and fewer post-installation defects are key to the cost-efficient implementation of building projects.

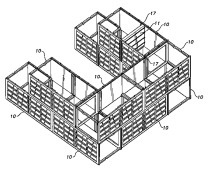

Module for serial prefabrication

Windowment can be integrated into all standard wall structures. Its use in industrial and serially prefabricated wall elements made of concrete or timber is particularly efficient. Whereas windows and shading systems were previously laboriously installed on-site into the wall modules, Windowment provides a time-saving alternative: the fully equipped modular frame is precisely positioned on the formwork surface of the precast pallet before concreting or inserted automatically in timber module production.

Windowment is also flexibly applicable in traditional masonry construction. It can either be bricked in directly or inserted from above into a pre-prepared opening – for example, before the ceiling slab above is concreted. This applies to wall structures made of masonry, panel elements, or precast concrete.

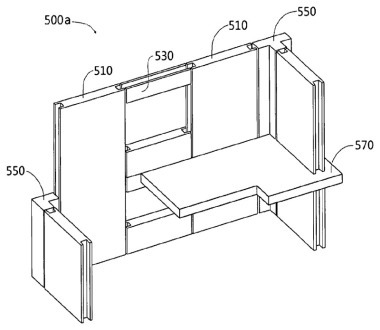

Serial production with a focus on quality

The multi-award-winning Windowment modular frame consists of a four-sided closed, highly thermally insulated load-bearing frame with high dimensional stability. It is individually configurable and includes, in addition to the window, roller shutter or external venetian blind boxes complete with curtain and drive. A two-part insulated guide rail system and thermally insulated reveal elements are also part of the system. The interior surfaces are suitable for painting or wallpapering, while the exterior surfaces can be plastered. Thermally separated connection components for window sills or floor screeds can be integrated. Factory-assembled waterproofing solutions for floor-to-ceiling window connections are also available.

Installation under controlled conditions

The Windowment modules are pre-assembled according to precise planning and delivered to the window manufacturer. There, the windows are installed into the frame under optimal conditions – regardless of weather, with technical support, and in accordance with recognized installation guidelines. The completed elements are packaged and transported to the construction site or precast plant, where they can be installed just-in-time or stored protected until installation. Thanks to certified crane lifting points, quick and precise positioning is possible. The modules remain securely packaged until final acceptance; disassembly of individual components is not required.

Time savings and reduced rework

Serial pre-assembly in the workshop not only eliminates work steps on-site – it also allows follow-up trades to begin earlier. Installation requires fewer personnel and no manual lifting. Protected delivery until final acceptance reduces rework and lowers defect rates. The compact, adaptable construction and factory pre-assembly of all components lead to demonstrable reductions in construction time.

CONTACT

Beck+Heun GmbH

Reinhold-Beck-Straße 2

35794 Mengerskirchen/Germany

+49 6476 9132 0