Greenpark – New living quarter built in serial construction in Berlin

Thanks to prefabricated structural members, construction works at the 15 residential buildings of the „Greenpark“ project are progressing rapidly in Berlin. Schöck Isokorb CXT and Schöck Sconnex prove to be the ideal solution for a reliable thermal separation of vertical thermal bridges in the building envelop, the parapet and the reinforced-concrete walls.

Thanks to prefabricated structural members made in the precast concrete factory, construction works are progressing rapidly at the 15 residential buildings of the „Greenpark“ project in Berlin. Here, 860 homes are being built, including 100 social housing units. Start of construction works was in April 2024. Total completion is scheduled for spring 2026. The building products Schöck Isokorb CXT and Schöck Sconnex prove to be the ideal solution for a reliable thermal separation of the vertical thermal bridges in the building envelop, the parapet as well as the reinforced-concrete walls in the basement and the underground parking lot. The load-bearing thermal insulation elements satisfy the specific requirements of serial construction quite particularly.

Efficient construction processes through thermal break

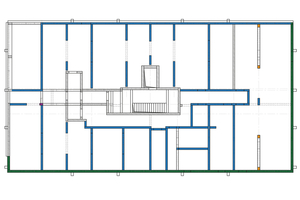

The new „Greenpark“ living quarter is situated on Buschkrugallee in the south of Berlin‘s district of Neukölln on the site of a former public swimming pool covering approximately 30.000 m². The urban development ensemble, that is upgraded by communal areas such as fitness areas, playing and sports fields, creates with an overall living space of 36,000 m² new and urgently needed housing space in Berlin. The design was created by ioo Architekten Elwardt + Lattermann based in Berlin. In 2024, Bauwens based in Cologne joined as project developer.

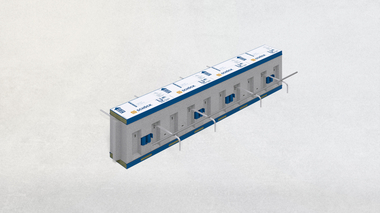

The buildings were constructed by the Bielefeld-based Goldbeck construction and service company. Goldbeck stands for systematized and serial construction. The company, for example, is prefabricating essential structural members at the own factory and assembles the same on the construction site in an exactly fitting manner. This allows for short construction times.

Affordable housing space through serial construction

In view of increasing construction costs, it is more and more difficult to realize affordable living space. This challenge is addressed by Goldbeck with holistic processes, which are simplified and accelerated by means of special product solutions and new approaches. In this way, the load-bearing thermal insulation elements made by Schöck for the thermal separation of structural members could also be seamlessly integrated into the construction process.

The manufacturer of building elements had already been involved in planning at an early stage and, in cooperation with the construction company, they developed special solutions adapted to the specific demand

of precast construction. „We highly appreciate the positive collaboration with Schöck in this energy-related demanding project,“ states Dennis Pohl, development engineer at Goldbeck.

Schöck Isokorb CXT type A instead of flanking insulation

In case of the Greenpark project not only the demands in terms of construction time were high, but also in terms of energy efficiency. For the thermal separation of the parapets planned for all buildings, the Schöck Isokorb CXT type A was the ideal solution because of its specific characteristics: The thickness of the insulating element of 120 mm and high-performance components make the load-bearing thermal insulation element an energy-efficient alternative for thermal decoupling of parapets and balustrades as against wrapping with insulation material. With Isokorb CXT type A more slender structural members with fair-faced concrete surfaces can be realized – with correspondingly gaining in floor space and visual appearance. In order to create a continuous thermal insulation level for a reliable separation of the parapet, the Part Z intermediate insulation was used additionally.

Quick to install and free of maintenance

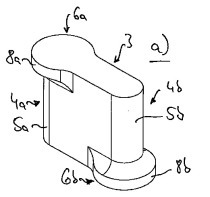

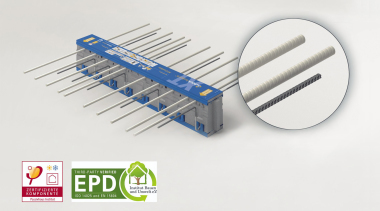

Another important issue was the ease of installation. Schöck Isokorb CXT type A is the first Isokorb element without steel with a national technical approval. Its bars made of the Combar glass fiber composite absorb tensile forces, while the concrete bearings absorb the compressive and shear forces. Compared to conventional solutions using bent reinforcing bars, the product concept consisting of Combar tension bars and concrete bearings, moreover, has the advantage that the thermal insulation element can be inserted into the floor slab reinforcement in a virtually corrosion-free manner. Thanks to application-related and tested verifications, no separate reinforcement is required on site.

The Schöck Isokorb CXT type A element is simply placed on the floor slab formwork and can be installed in five minute, including position fixing. These are optimum conditions for the concept of serial construction, designed for speed and cost-effectiveness.

Customized solution with integrated mounting support

In order to simplify and to optimize the construction process even more, Schöck developed a special, new system in collaboration with the Thomas Allton GmbH precast concrete plant assigned by Goldbeck. The aim was to reduce additional works on the construction site and to allow for as much industrial prefabrication as possible. Therefore, the Schöck Isokorb CXT type A was to be installed into the reinforced-concrete parapets already in the factory, being then delivered to the construction site as a completely assembled precast element.

A customized solution was designed to protect the Combar rods protruding downwards against damages during transport and installation of the completely precast elements: In the precast factory, the insulating part of the Isokorb CXT was drilled through centrically, allowing the mounting support made of Combar to be inserted and embedded in concrete inside the wall. The headed stud at the protruding end of the bar, serving as installation base, allows for reliable and efficient positioning on site.

Reduction of working steps

Two different construction methods were applied for the parapet: For the precast floor slabs, the completely precast wall elements were provided with recesses on the top, into which the balustrade elements were inserted. Simple additional reinforcement ensures the connection with the slab reinforcement. Afterwards, only the concreting recess had to be filled to connect floor, wall and parapet with each other in one step. In case of the semi-precast elements, the balustrade elements were placed on the floor slab reinforcement and were embedded in concrete in one work step when pouring the in-situ concrete topping.

André Brendel, installation foreman at Schöck with many years of practical experience as foreman in building construction, instructed the workers on the construction site and is excited: „As the Schöck Isokorb CXT type A has only straight bars, the installation is very easy to handle and requires little control. One explanation is enough to get it right.“ The new system needs only a few working steps, which he briefly lists: „Put it in, fix the position, pour concrete, remove the position protection, done“ and adds: „The new installation solutions for the Schöck Isokorb CXT type A for parapets promotes serial construction ideally.“

Connection without thermal bridges

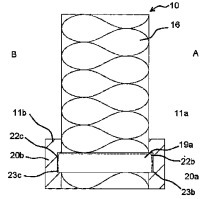

A product of Schöck was also used as thermal separation of basements and underground parking lots from heated living spaces: In this case, the connection to the building was made with the Schöck Sconnex type W for reinforced-concrete walls. „In this project, we had to provide a lot of structural members with a thermal break,“ explains Lars Handschuh, planning coordinator at Goldbeck, and states: „Hence, in the sense of cost-effective construction, for example, everything is streamlined and optimized. The thickness of the thermal insulation in exterior wall areas amounted to 14 cm only. We needed a good solution here to avoid thermal bridges. Schöck Sconnex was exactly what we were looking for, and it worked excellently.“

Schöck Sconnex in a special application

Schöck Sconnex type W prevents the heat flow from the basement walls into the ground slab and allows the elimination of flanking insulation. In the Greenpark project, the basement walls were built of semi-precast elements as reinforced-concrete wall elements, what meant a special application for the Schöck Sconnex type W. In this case, the component was put on the wall shells consisting of reinforced-concrete wall elements at the intended positions before they were poured with concrete. Afterwards, the Part Z intermediate insulation elements were installed to provide a complete and secure thermal break. Wherever column heads required a concentrated, energy-efficient load transfer, the Schöck Sconnex type P element for reinforced-concrete columns was used supplementally.

Convincing standard solution

At this application, Schöck Sconnex as a standard system solution could score with a smooth installation and in structural terms. „Using Schöck Sconnex, we could do without any flanking insulation which often did not work in geometrical terms, thus achieving the requested energy-related quality of the building,“ reads the positive conclusion of Lars Handschuh, who can well imagine to opt for Schöck Sconnex again in case of similar projects and boundary conditions.

CONTACT

Schöck Bauteile GmbH

Schöckstraße 1

76534 Baden-Baden/Germany

+49 7223 967-0