Rotor straightening machines for rebar with the latest maintenance-free 5G rotors

Eurobend has more than 30 years of experience in the construction of CNC controlled machines and offers a wide range of equipment for the rebar processing, such as 2D and 3D automatic stirrup bender, straightening and cutting machines with one or more lines, mesh welding machines, welding machines for the production of spacers and much more. The range of rebar processing lines includes a variety of programmable high performance rebar straighteners, the MELC series, designed for continuous heavy operation in the construction industry.

Milestones in rotor straightening technology

The straightening method is based on the principle of the rotor with hyperbolically profiled rollers, which was developed and presented by the Eurobend engineers in the early 1980s. The system has been further developed since. Meanwhile, the maintenance-free 5G rotor with eight hyperbolic rollers (patent) is the Eurobend standard.

The new straightening machines of the MELC series offer a number of advantages:

No adjustments of the hyperbolic rollers necessary;

The rotor is maintenance-free, i.e., self-cleaning and self-lubricating. The roller life time is over 3 years;

The best possible straightening quality is produced, better than 1/1000;

No marking of the wire surface;

Up to 40% savings of energy costs;

Mechanical simplicity of the machine. The rotor itself provides both the feed and the straightening of the wire and is maintenance-free;

The wire is cut with flying shears without stopping or slowing down the wire feeding.

The constructive simplicity of the system allows the manufacturing of machines with up to six (6) rotor lines that can be operated simultaneously and independently. Each line can process a different diameter and has its own measuring, cutting and collection system. Each of the simultaneously working rotor lines can produce a different order.

The different rotor sizes cover the diameter range from Ø6mm to Ø26mm for rebar and stainless rebar. With the multi-rotor configuration, up to 500 m/min of rebar can be processed in continuous operation.

Innovative design concepts cover every need

Depending on the size and specialization of the customer (dealer, rebar shop, precast plant or mesh producer), the way the company works (diameter or order-related) and the required productivity, Eurobend can offer the optimal machine concept from the MELC series with 5G rotors of the new generation:

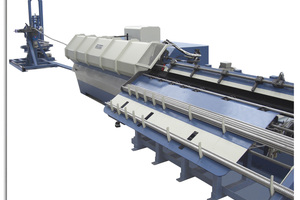

MELC Monoline Series

This series offers models with one rotor with feed speeds of up to 120 m/min. Different variants cover the range from Ø4mm to Ø26mm.

The rotor is frequency inverter controlled and can therefore be adapted to current operational requirements. Adjusting the speed accordingly will extend the life of the consumables and the machine.

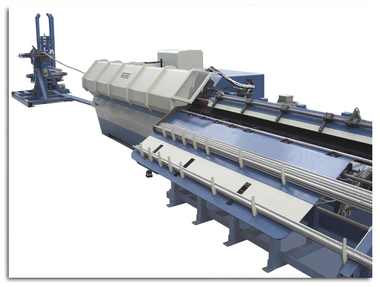

MELC Flexiline series

The ultimate, breaking-through solution for precast plants -various models with three (3) up to six (6) rotors and with common measuring, cut-off and collection system, covering the diameter range from Ø6 up to Ø26mm. Cutting is performed with flying cutter (standard on all MELC models).

These models offer the highest flexibility on the market. The diameter change takes less than three seconds without moving mechanical parts (patent). Small and large batches can be produced one after the other without any loss of time or logistics, each of which can consist of different diameters and lengths. A complete range of Flexiline straighteners with an integrated double bending system, the Syntheton, cover the diameter range from Ø6 - Ø26 mm.

The servomotors of the Syntheton 2-head bending system ensure excellent precision, both when bending and when positioning the bending heads. Diameter changes in less than three seconds. The bending tool change is fully automatic in „0“ time - all bending diameters are integrated in a sophisticated bending tool.

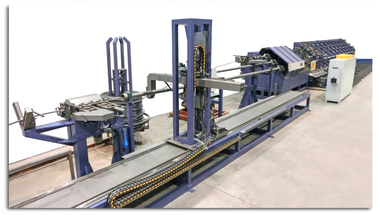

MELC Polyline series:

High productive straightening systems for large rebar shops and mesh producers – models are offered with two (2) up to six (6) rotor lines that can be operated simultaneously and independently. Each line can handle a different diameter and is equipped with its own measuring, cutting and collecting system. Production speeds of up to 500 m/min can be achieved in continuous operation.

Rotors covering from Ø6 mm up to Ø26 mm can be combined in one machine. The models of this series can be equipped with various automatic product handling and logistics systems: automatic bundling stations, coil opening robots for diameters 20 and 25mm, bundle sorting systems.

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980