Max introduces a new solution for cutting small-diameter rebar

As the pioneer of rebar tying tools, Max is launching the cordless wire mesh cutter WMC80, designed to significantly reduce physical strain on workers. Weighing only 2.8 kg including the battery, its compact body can cut rebar with diameters from 3 to 8 mm in just 0.7 seconds per cut. With a simple pull of the trigger, you can cut rebar effortlessly with one hand, reducing physical burden while further enhancing on-site work efficiency. What Max brings with the WMC80 is an entirely new solution for precast factories worldwide.

The aim of “WMC80”

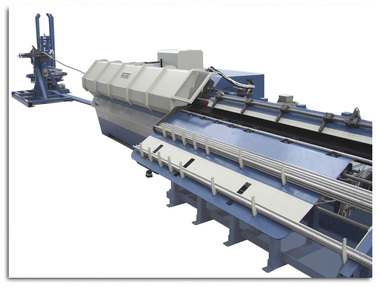

Wire mesh, truss bars, and rebar are commonly cut using manual bolt cutters, grinders, or pneumatic cutters with hoses. These methods place a heavy physical burden on workers, while some tools pose safety risks such as scattering sparks. In some factories, workers are required to make more than 500 cuts per day, making this a harsh and demanding task.

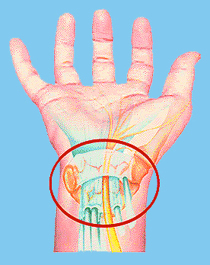

The WMC80 can cut rebar with diameters ranging from 3-8 mm in just 0.7 seconds per cut, and it is capable of cutting two overlapped rebars at once (up to 6 mm). In particular, precast factories benefit from its compact body and cordless operability, which allow highly efficient cutting work such as panel openings or on-table processing.

As the construction industry faces a shortage of skilled labor, there is a strong demand for mechanization to improve working conditions and productivity. With the introduction of the WMC80, Max aims to reduce the physical strain on workers and enhance the efficiency of cutting operations.

Specific features of “WMC80”

1. Cuts rebar with diameters from 3 to 8 mm in just 0.7 seconds per cut.

2. One-hand operation is possible simply by pulling the trigger, allowing the other hand to support or move materials, improving both safety and work efficiency.

3. Equipped with a “rubber cushion” to minimize scattering of cut-off pieces.

4. No sparks are generated during cutting, and being cordless, there is no risk of tripping over cables or hoses. An auto power-off function ensures safety when the tool is not in use.

5. Compact design and lightweight at only 2.8 kg (including battery).

6. Capable of up to 1,400 cuts of 6 mm rebar or 1,000 cuts of 8 mm rebar per charge. Uses the same lithium-ion battery as Max rebar tying tools.

The Mission of Max

Max is a pioneer that launched the world‘s first battery operated rebar tying machine as a hand tool in 1993. Since then, it has been highly praised for improving productivity and reducing the workload.

“Making work life easier and more enjoyable worldwide”: Under this corporate vision, Max CO., LTD. focuses on „making products that fully satisfy the people who use them. Max will continue answering to the needs of its customers by following the strict jobsite-oriented principle and customer first policy, creating and introducing unique products around the world. By doing so, Max will contribute to making the lives and work of customers more convenient and easier, which make Max a company that can exist through steady progress and also give back to the society.