Masa realizes major project for Consent LLC – new plant in Abu Dhabi for exclusive products

At a time of construction boom in the United Arab Emirates, Consent LLC is sending out a clear signal: The new high-tech production plant in Abu Dhabi, developed and built by machinery specialist Masa GmbH, supplies exclusive building materials for a demanding and fast-growing market.

Major projects such as the new terminal at Al Maktoum Airport and numerous other construction projects in the United Arab Emirates are driving demand for high-quality building materials. One of the reasons for this is that the UAE wants to position itself as an important industrial location with government initiatives and new economic partnership agreements. The ten-year ‘Operation 300bn’, for example, aims to strengthen and expand the UAE‘s industrial sector and increase its contribution to GDP from AED 133 billion to AED 300 billion by 2031. Local companies are responding to this trend by expanding their production capacities. They are focusing primarily on local procurement.

Consent LLC, one of the major players in the production of building materials in Abu Dhabi/the UAE, invested heavily in a new production plant in response to the local construction boom. Plant IV impresses with its dimensions and sets new standards in the industry. Masa accompanied the project from initial planning to commissioning and marketable production. The plant fulfils the highest standards of exclusivity, efficiency and cost control – and thus strengthens the local industry in the long term.

“We wanted an exclusive plant for exclusive products”

Alan Sakr, Owner of Consent, summarizes his expectations in approaching Masa as a partner for the plant equipment. ‘The market is highly competitive, and our customers’ demands are increasing. That is why we wanted to invest in an exclusive plant that would enable us not only to meet our customers‘ expectations, but to exceed them. At the same time, we need to ensure that our productivity and cost targets are met.’

Exclusivity, productivity and cost control – three clearly defined goals that require equally clear technical solutions. Cristian Brugioli, Managing Director of the Masa Middle East branch in Dubai, has maintained a close business relationship with Consent for many years and is very familiar with the company‘s priorities. Plants I and II have been successfully producing with Masa technology for a long time. If he had to describe Plant IV in just one word, the word ‘unique’ would immediately come to mind.

The plant in Abu Dhabi is unique in many respects. In order to fulfil the three main objectives in equal measure, the Masa team worked closely with Consent to develop the layout for a Masa high-tech plant with Multi-Handling Systems, which includes a first-in-first-out solution and the integration of comprehensive finishing lines.

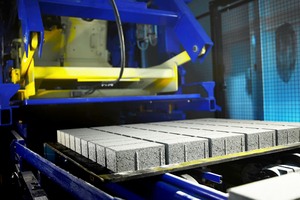

The products are manufactured on a Masa XL-R 9.1. The Masa Multi-Color System enables repeatable, excellent color designs. In order to ensure that each exclusive product meets the high customer requirements and to minimize the risk of contamination, the layout also provides a separate feed of the aggregates for the main and face mix concrete.

First-in-first-out Solution

The chamber system at Consent, where the products cure, can effectively accommodate over 8150 production boards. It therefore offers sufficient space for both standard and exclusive products with lower order volumes. Fast availability is a decisive factor, especially for these products. The Masa plant layout takes this special requirement into account when implementing the storage and retrieval logistics with two Masa finger cars: the cured concrete products are removed according to the batch-based first-in-first-out (FIFO) principle. The use of the chamber system should be as cost-, space- and time-efficient as possible while allowing control over the production processes.

Multi-Handling Systems

To be able to react flexibly to changing customer requirements and market demands, Consent relies on just as flexible production processes. The Masa plant layout with its multi-handling systems and two dry sides meets this requirement: It offers Consent the possibility to take both uni products and concrete products that require finishing or post-treatment almost simultaneously from the chamber plant. Dry side I with Cuboter I primarily ensures fast handling and accurate cubing of the uni products.

Dry side II can realize its full potential with exclusive products. Alan Sakr is particularly proud of one solution here: ‘The joint result of very open and fruitful discussions between the project managers at Consent and Masa is the very flexible handling on dry side II via a single layer shifter. Depending on the order, the shifter operates either the finishing line for split concrete products or the second finishing line for shot blasting treatment. After the two finishing lines, all the products come together again at the Masa Cuboter II. The system is really ingenious and required a great deal of dexterity on the part of the Masa programmers.’

Multi-Color System

Customers focus their attention on concrete products with an appealing and exclusive look. The coloring of the Consent range is created by another Masa component, the Multi-Color System ‘Premium’. The system includes a dosing unit, swivelling belts and a frequency-controlled collecting belt. The dosing unit consists of easy-to-clean stainless steel silos incl. cleaning flaps and load cells per silo. Different color combinations are stored individually and recipe-specifically and can therefore be repeated exactly. Alan Sakr summarizes the advantages of the Masa Multi-Color System: ‘The system allows us to dose each individual color mixture more precisely, sequence the color mixture and have better control over how the end product will look. Ultimately, this enables us to offer our customers a wider range of options for multi-colored products.’

‘It‘s amazing how easy the plant is to operate – despite its enormous complexity.’

Especially at the beginning of the commissioning phase, the Consent team approached the highly complex plant with great respect. However, thanks to the intensive familiarization and training provided by Masa, their confidence in the machine technology grew day by day. The Consent team learned to pay attention to the intricacies of plant operation and took the opportunity to ask detailed questions. Masa is aware of the importance of this training, which can ultimately determine the success of a plant. Another key success factor is the operability of the plant. Alan Sakr emphasizes three key points that give his staff confidence in their daily work and enable quick orientation and reaction:

the clear and uniform visualization of the entire production plant in the Masa plant control software;

the clearly structured and comprehensible instructions in the user guidance;

the alarms and troubleshooting instructions in the event of faults.

‘The time and energy that Masa has invested in developing its own plant control software pays off for us every day,’ summarizes the Consent Owner. ’The plant talks to us and guides us through all these complex processes. This is much more than just aesthetics in visualization.’

‘For us, reliability is the key to a successful business partnership.’

For Masa and Consent, reliability is a central aspect of successful business partnerships. Throughout the entire course of the project, this included, for example, adhering to agreements regarding product quality, delivery deadlines and quality standards. Mutual, transparent communication was also crucial in the planning and implementation of the project. Problems and challenges were addressed at an early stage in order to find solutions together.

Reliability is also closely linked to the durability of Masa machines and plant components. For Consent, this means planning security in terms of productivity and operating efficiency, as well as low downtimes. However, reliability does not end with the completion of the project: Consent can count on the comprehensive Masa After-Sales Service, which offers tailored support and assistance throughout the entire machine life cycle.

Site diary in time lapse – from the groundbreaking to the acceptance

Sun, 27 degrees Celsius, blue sky. It is 7:30 a.m. local time when construction crews arrive in the Khalifa Economic Zones Abu Dhabi with machinery to move tons of sand and stones in the coming months. Mark out the foundations and excavate the foundation pits. Create formwork, pour concrete and insert reinforcements. The completed foundations only give a hint of the enormous production plant that opens its doors here about a year later.

Steel. As far as the eye can see. Steel beams, steel frames, steel struts are delivered. Machine frames precisely aligned. Everything is geared up for the big day when the first low-loaders arrive. With parts and components that will gradually be assembled into a high-tech plant.

4,934 kilometres as the crow flies lie between the Masa production facility in Andernach, Germany and the Consent plant in Abu Dhabi, United Arab Emirates. 28 days of transport by land and sea for all individual parts of the Masa block making machine, which will now be carefully assembled, wired and later commissioned by the Masa Service Team Middle East. Just like the other components of the plant, which will arrive here bit by bit. A total of 30 containers and two additional low-loaders.

A record pace on the construction site. Meanwhile, it is easy to see where the products will later be freshly manufactured, cured, processed and packaged. Kay Rosengarth, Chief Engineer in the Masa Service Team, has his team and the supporting Consent specialists well under control. So far, only the skeletons of the buildings are standing.

The outside areas, building cladding and inside areas are increasingly taking shape. Safety equipment, cables and cable trays, control cabinets. Randomness is not an option. The schedule is tight, the deadlines for commissioning have to be met, including test runs with and without material.

The first pavers. In the hall of Plant IV, two feelings prevail at this moment: relief and pride. Relief that all plant components work together harmoniously despite their dimensions and complexity. And pride in the fact that a unique block and paver making plant has been built here for Consent in the Middle East.

As of today, Plant IV produces high-quality concrete products for the Arab market. The plant processes up to 1,000 tons of raw materials into fresh concrete products every day, transports them to the respective further processing stations and finally packages them into product cubes that are ready for transport. Everything is done automatically, with fast cycle times, high quality and high availability.

CONTACT

Consent LLC

Al Quoz Industrial Area 1

Dubai/United Arab Emirates

+971 4 3472011

Masa GmbH

Masa-Str. 2

56626 Andernach/Germany

+49 2632 9292-0