Interview: „An option towards greener architectural

concrete“

On the occasion of this year‘s BetonTage congress held in Ulm, Dyckerhoff introduced its newly developed CO2 reduced cement „Dyckerhoff Weiss BLUE STAR“. For the first time, there is now a white pozzolan cement, exhibiting a significantly improved ecological footprint (see also BFT 9/2023 p. 56/57). The BFT editorial staff and Martin Möllmann (Dipl.-Bau-Ing. Dipl.-Wirtsch.-Ing.), who is responsible at Dyckerhoff for the business areas product marketing as well as sales of white cement, talked about what is behind this innovation and which goals Dyckerhoff is pursuing with it.

BFT International: White cement only has a relatively small share of the entire cement market, Mr. Möllmann. Why did you anyhow put great effort into research and development for reducing the CO2 portion of white cement as well?

M. Möllmann: If you look at the market of cement as a whole, then the share of white cement of around one percent is certainly small in relation to this. However, white cement is a very important building material for a lot of construction tasks. Since the 1930s, when the Dyckerhoff Weiss brand had been developed, white cement has become above all an indispensable architectural building material, for example, in the field of fair-faced concrete. Therefore, we have a large number of customers, who mainly work with our white cement, and some even exclusively. These are often customers who manufacture high-quality products particularly. They too – like us as cement producer – have a responsibility for the environment and, of course, they are also asked by their customers what they do to decline their carbon footprint.

BFT International: To what extent do the political guidelines play a role here, too?

M. Möllmann: Of course, we are also guided by them. Because decarbonization of cement and concrete, and thus the reduction of their greenhouse potential is undoubtedly one of the major eco-political and social challenges of our time. Politics has stipulated the demands in this regard clearly and unambiguously: Germany is to be climate neutral by 2045. We at Dyckerhoff feel also committed to this goal and are working to transform our product portfolio gradually into a „green“ future. Last year, we brought already two CO2 reduced gray cements to the market with Dyckerhoff Eco Comfort and Dyckerhoff Cedur. And now, with Blue Star, the first CO2 reduced white cement. It perfectly complements our application-oriented product range of white cements that is optimized for different fields of application.

BFT International: How exactly has Dyckerhoff managed to reduce the portion of CO2 in white cement?

M. Möllmann: As for all cements, the carbon footprint for white cement is determined by the clinker content. If we want to reduce this portion, then there will be special requirements on the future raw materials, namely those materials which are to substitute clinker. Along with blast-furnace slag, fly ash or limestone, this also includes pozzolans. And in the development of Blue Star, we have now focused on these natural pozzolans in particular.

BFT International: Why have you decided to use pozzolans?

M. Möllmann: For some time now, our experts have been dealing with alternative raw materials for the production of white cement in order to minimize the CO2 footprint. Searching for an appropriate clinker substitute, our internationally networking R&D organization was of benefit to us. Our central research and development facilities also include the Buzzi Unicem Innovation Lab. and Technology (BUILT) in the Italian city of Vercelli, apart from the well-known Wilhelm Dyckerhoff Institute (WDI) in Wiesbaden. The close exchange between these R&D institutions has led to the fact that pozzolans, which are virtually a standard product in Italy, were taken into stronger consideration by us, too. In addition, we were able to integrate white pozzolans in our white cement products quite well, as tests have revealed in the run-up. The production was carried out in our Wiesbaden cement plant that is CSC Gold certified.

BFT International: For a better understanding – what are natural pozzolans actually? How and where did they originate?

M. Möllmann: Natural pozzolans are primarily of volcanic origin. The name originates from the Italian city of Pozzuoli west of Naples, where in ancient times large quantities of pozzolanic volcanic ash were already extracted. Therefore, construction with these materials has a long tradition in the Mediterranean region. This started already in the Roman Age and continuous till today.

BFT International: So, what are the advantages of natural pozzolan exactly?

M. Möllmann: Pozzolans are composed of silicic acid, alumina, limestone, and alkalis. The interaction of the silicic acid with calcium hydroxide and water results in a pozzolanic reaction. Our pozzolan cement is characterized by a high early strength, a better sulphate resistance and a lower tendency to efflorescence, among others, while featuring a comparable durability. Hence, pozzolans meet the requirements defined by us for the future raw materials concerning strength, durability and, of course, the color as well.

BFT International: What about the important criterion of color?

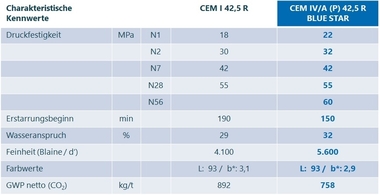

M. Möllmann: For us, it was decisive that not only about 15 % less CO2 is released in the production of the Dyckerhoff Weiss Blue Star in comparison to our white CEM I cements. It was just as important to us that, ultimately, we get the same and, above all, consistent color as with our other white cements; after all, this is precisely the USP of Dyckerhoff Weiss and therefore a significant criterion in the development of new white cements.

BFT International: Since when do you have the new white pozzolan cement Blue Star in your white range?

M. Möllmann: This white pozzolan cement was approved by VDZ (German Cement Works Association) with the standard designation of CEM IV/A (P) 42,5 R in mid-June and since then, it has been sold at the Amöneburg factory under the name „Dyckerhoff Weiss BLUE STAR“.

BFT International: You have presented the Blue Star to the industry on this year‘s BetonTage held in Ulm, for the first time. What reactions did you experience there?

M. Möllmann: The presentation of Blue Star took place quite deliberately at the time you mentioned. We intended that the relevant market comes to know about it on a key date. Moreover, here the product could be launched perfectly because our experts had the opportunity to explain the new white cement in detail during personal discussions at our exhibition booth in Ulm. In addition, there was a well-attended innovation forum where our sales manager, Christian Bechtoldt, introduced Blue Star in an exciting presentation to the professional audience in Ulm. Both at the booth and following the presentation, we could notice an enormous interest in the innovative product.

BFT International: What happens next? Which future developments can we expect from Dyckerhoff?

M. Möllmann: Of course, we are thinking ahead and are constantly considering what is needed in the market. In doing so, we also explore the question of which additional options are still available for reducing CO2 emissions. In our already above-mentioned, efficient research and development laboratories, we are already working on corresponding projects. We expect specific results as early as the second half of 2024.

BFT International: Mr. Möllmann, many thanks for the conversation und much success furthermore!

Interview: Dipl.-Ing. (FH) Silvio Schade, Editor-in-Chief BFT International

CONTACT

Dyckerhoff GmbH

Biebricher Straße 68

65203 Wiesbaden/Germany

+49 611 676-0