90 years of Dyckerhoff Weiss: a trademark writes history

In the year 2021, Dyckerhoff looks back on 90 years of history of its white cement production. Since first appearing on the market in 1931, Dyckerhoff Weiss has evolved into an internationally renowned trademark that today is often used as synonym for white Portland cement.

How it all began

The name Dyckerhoff has been a worldwide symbol for cements and construction material already since 1864. Since 1931, white cement has been an integral part of the Dyckerhoff product portfolio and, analogous to the earlier gray cement varieties, Dyckerhoff Normal and Dyckerhoff Doppel, it was given the name Dyckerhoff Weiss. Already in 1870, i.e., shortly after the foundation of the company, the chemist and engineer Rudolf Dyckerhoff experimentally burnt, in a shaft kiln, smaller quantities of white cement. But the time had not yet become ripe, especially since the gray cement was then still a young up-and-coming construction material that required full commitment.

It took more than five decades before the white cement once again came into focus. In 1925, Dr. Walter Dyckerhoff brought back from a trip to South America not only ground slabs of high visual quality – called Mosaicos – that were characterized by the color of the binder, but at the same time was the first to bring the idea of white cement to Europe to stay. So, already a short while after, the subject of white Portland cement was again taken up in Wiesbaden – and this time with lasting success. On 1 July 1931, after six months of testing, the cement was on the way to the customers.

Close collaboration with the market

That Dyckerhoff Weiss became a genuine trademark already so soon, was among other reasons due to the continuous and close collaboration with all customer groups – from manufacturer and processors of concrete and mortar products all the way to planners and architects. From the very beginning, Dyckerhoff experts endeavored to familiarize themselves with the processing technology of their customers. They had recognized that a construction material primarily used for its design functions also has to satisfy quite individual requirements in the respective further processing stages. Dyckerhoff Weiss was also a pioneer in using current marketing instruments. Already in 1935, for example, UFA shot a 30-minute training film on the various applications of the white Portland cement whose interesting aspects of production technology can serve as a model to this day.

The regular presentation of Dyckerhoff Weiss at the major trade shows was also an important communications medium. The best example for this is the biennial Bau in Munich. Not only the current projects were presented there, but “white concrete to touch” was also always featured. Unforgettable the sweeping bridge featuring elegant with some very slender precast elements of white cement on which the ballet of the Munich State Theater danced. Also spectacular were the legendary staircase projects “Stairway to Heaven” with their steps of different colors, and later the first unsupported white Nanodur staircase that quickly became the talk of the trade show. And when more than a decade ago the idea of the jointless concrete floor in the form of Dyckerhoff Terraplan was added, it likewise became a much-admired eye catcher at the Munich fair stand for its elegant appearance.

Long list of outstanding projects

The list is long of outstanding projects that Dyckerhoff Weiss implemented in past years. What must be the most prominent building is the new Federal Chancellery built between 1997 and 2001 in Berlin based on designs of Axel Schulte’s and Charlotte Frank. Impressive also is the NS Documentation Center in Munich planned by Berlin GWS Architects, a white cube that appears to be cast from a single mold and is a successful symbiosis of precast elements and in-situ concrete. More than 8,000 precast elements of white marble concrete also characterize the Neue Museum in Berlin designed by David Chipperfield – one of the most spectacular museum newbuilds of our time. The Niemeyer Sphere in Leipzig is also especially spectacular – visionary architecture of one of the most famous architects of modern age, made of white concrete. Currently, the imposing chalice-shaped columns in the Stuttgart 21 underground railroad station are supplied with Dyckerhoff Weiss.

Production takes place in Wiesbaden-Amöneburg in Germany, Dyckerhoff’s headquarters. Here, two types of Portland cement are produced in accordance with the cement standard DIN EN 197-1 in strength classes 42,5 und 52,5 in the qualities “Face” for precast elements and for cast in-situ concrete elements, “Contact” for fine mortar, “Decor” for pargets and mortar, “Speed” for the special construction chemistry as well as “Strong” for concrete goods and the construction chemistry sector.

The basis for the superior qualities of the end products is a special clinker grinding concept. Here, differentiated between according to the areas of application, selected sulfate agents are used in finely balanced mixture ratios. The ready-ground white cement is finally passed through a cement cooler where it is cooled down to max. 60 °C, which is an important criterion for construction chemicals, in particular during hot summers when using methyl cellulose.

Trend-setting investments

Operational efficiency at the Amöneburg location has been continuously optimized by a range of trend-setting innovations. These include a new central control station that also serves, in addition to process control and supervision, for quality control of production. In addition, there are two new loading lanes at which, during peak times, more than 300 tons of bulk white cement can be filled into silo trucks. The white cement is shipped from Wiesbaden to destinations throughout Germany, as well as to Austria, Switzerland and to the Benelux countries and France.

Dyckerhoff met the demand for application-friendly products in particular with its new development Dyckerhoff Flowstone. The basis for this product is an especially screened white cement that is combined with ultrafine binders. In this way, together with a matching combination of admixtures, an extremely fine-particle compound is obtained. The customers, in production, then individually mix Flowstone with aggregates to suit their needs. Concretes made on the basis of Dyckerhoff Flowstone achieve tensile-strength values of up to > 15 MPa and compressive strengths of > 100 MPa. The application possibilities of Flowstone are particularly complex, molded parts as well as thin-walled elements. Flowstone, moreover, is today also increasingly used as an architectural construction material because, with its application, it is possible to manufacture very slender construction elements with high-quality surfaces and considerable reductions in cross-section.

45 years of Info-b

An important institution, also for marketing Dyckerhoff Weiss, is the cast stone information association Informationsgemeinschaft Betonwerkstein e.V. – Info-b for short. It was founded in 1976 by Dyckerhoff in Wiesbaden as the first joint advertising campaign for concrete products: at a time when marketing for most construction materials was still unheard of. But, already then, market challenges had to be faced and given new impulses. Then as now, the focus was on targeted communication with planners and architects. The instruments that were used here, and that are used to this day, range from public relations work and advertising in technical publications, to participation in regional and supra-regional exhibitions and trade shows. For this, the over 130 Info-b members together raised a marketing budget used exclusively for marketing cast stone.

Look into the future

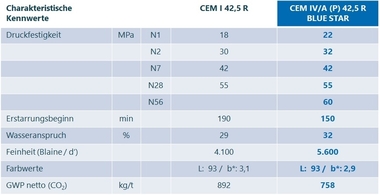

For production of white cement, a technique for a more sustainable manufacturing method was found by using, to a high degree, secondary raw materials, as well as alternative energy sources. To reduce the clinker factor, tests are underway for the manufacture of alternative white binders: e.g., based on CEM II cement used with light interground admixtures such as light limestone meals or white pozzolans. This includes the CSA cement “Next Base,” which is based on calcium sulfoaluminate made in Italy, and which has already been part of the portfolio for five years.

CONTACT:

Dyckerhoff GmbH

Biebricher Straße 68

65203 Wiesbaden/Germany

+49 611 676-0