HVAC floor slabs for Dehoust GmbH and the heat transition

HVAC floor slabs based on semi-precast concrete elements provide an innovative solution for energy-efficient temperature control of modern buildings. By the integration of water-carrying tube systems into the precast concrete elements directly, a comprehensive system is created all over the surface with heating and cooling functions – being invisible, of low-maintenance and enabling building component activation. In particular, in office, educational institution and administration construction, these elements open up new opportunities to avoid problems due to overheating in the summer and to combine fast construction processes and freedom of design.

In cooperation, the Syspro member, Betonwerk Oschatz GmbH, and GeoClimaDesign AG located in Fürstenwalde have now equipped an administration building with HVAC floor slabs, exhibiting a concrete core activation particularly close to the surface, thus allowing for a very quick and targeted balancing of warmth and/or cold.

HVAC floor slabs for Dehoust GmbH

Dehoust GmbH based in Leimen, with subsidiaries in Nienburg, Heidenau and Eitorf, is a leading manufacturer of storage and container systems. The company, among others, is producing plastic containers made of polyethylene and large-volume storage tanks made of steel and stainless steel. For making optimum use of energy, the company is producing heat buffer tanks and cold water storage tanks of up to 250 m³. Process water management systems for the preservation of the resource water are an important part of their sales program.

The medium-sized company would also like to make a contribution to the energy transition in the context of the construction of a new administration building in the Saxon town of Heidenau near Dresden. Construction works started on the existing premises at the beginning of 2025. The new building will provide modern workplaces, meeting rooms and social areas on several floors. Great importances was attached to energy efficiency in the planning stage. Large window surfaces supply a lot of daylight, whereas modern building services provide for optimum climate conditions. Making use of renewable energy sources by means of a photovoltaic system installed on the roof is also part of the overall concept.

System integrated into building components for intelligent room air conditioning

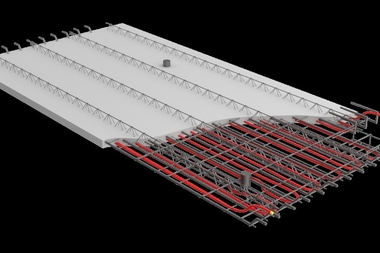

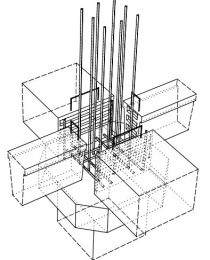

Especially noteworthy is the rugged system for heating and cooling of rooms that is integrated into the floor slabs, i.e. the ceiling elements. The advantage is that the ceiling, in contrast to the floor, is not covered by furniture, thus providing a completely usable heating and cooling surface that allows, above all, avoiding any overheating in the summer and creating a comfortable indoor climate.

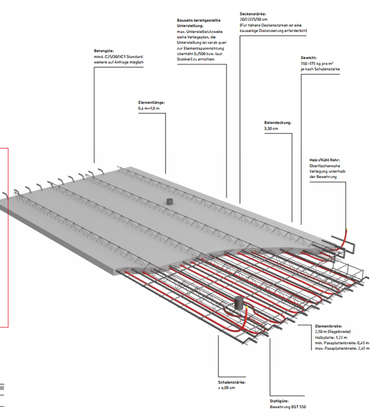

Daniel Schönherr, general manager at Betonwerk Oschatz, explains: „For quite some time now, our concrete plant has been dealing with semi-precast concrete elements with capillary tube mats integrated into floor slabs. Especially for the property of the Dehoust company in Heidenau, together with GeoClimaDesign AG, we have now manufactured HVAC floor slabs that allow for a particularly close-to-surface concrete core activation. The aim was to place the capillary tube systems as close as possible to the fair-faced concrete surface of the 800 m² of floor/ceiling elements installed here in order to reduce the reaction time for balancing heat and/or cold.“

Prefabrication to reduce assembly time and personnel expenses

The system made by GeoClimaDesign AG with the name „FILIblue“ that is used here is a prefabricated heating and cooling system for the integration into concrete components, in fact close to the surface. This system is a so-called concrete core activation and, according to DIN, belongs to the water-based surface embedded heating and cooling systems. Camila Vargas of GeoClimaDesign AG states: „This combination consisting of our FILIblue system and precast concrete elements was developed together with an industry partner and has already been used in this kind in various building types. In the planning process, the FILIblue systems are already adapted to the semi-precast slabs and the space situation, being then integrated into the semi-precast floor slabs directly at the concrete plant. This allows a high degree of automation and factory quality control.

The floor slabs are delivered directly to the construction project ready for installation. On the construction site, the elements only have to be connected – that saves time, reduces installation effort and cuts manpower requirements considerably.“ About one third of the assembly time can be saved for heating installation. HVAC floor slabs have a double function because they can not only heat, but also cool. The building owner saves to purchase two separate systems and can virtually cool for free in summer when using a heat pump – a storage tank made by Dehoust designed for heat and cold water storage provides for efficient operation of the heat pump. Thanks to the integration of the capillary tube system in the factory, there is no dependence on the weather and the need for clarification and coordination with other trades can be minimized in this way, what apart from the time saved also represents a financial profit.

Assured quality due to standardized conditions

Camila Vargas even sees further advantages. „Incorporating the Filiblue system already into the semi-precast elements in the concrete plant under standardized conditions serves better quality control and assurance, in contrast to the installation in cast-in-situ concrete on the construction site. The thermal performance is improved too: The Filiblue modules are extremely flat and the many fine small capillary tubes of the register are arranged close to the surface. An allocation across the entire area ensures high performance and due to the arrangement close to the surface in the semi-precast slabs, Filiblue HVAC floor slabs have a particularly quick reaction time,“ states Vargas.

The advantages are also reflected in a better indoor climate: By using an HVAC floor slab the building can be heated and cooled in a health-friendly and comfortable way. An HVAC floor slab works with radiant heat instead of convection. Therefore, there is no unpleasant cold draught and no dispersal of dust or bacteria. The silent cooling is very pleasant as well and, contrary to air conditioning systems, it does not cause cold draught or annoying noises. This contributes to a comfortable working climate in an office building and to heat protection in the summer. In addition, the technical equipment disappears discreetly in the ceiling. Walls and flooring remain free. In this way, space can be saved, which also saves money in new construction and increases the flexibility of use and the room aesthetics. The building was constructed by Karl Köhler GmbH located in Heidenau. The completion of the building is scheduled for early 2026.

CONTACT

Syspro-Gruppe Betonbauteile e. V.

Matthias-Grünewald-Str. 1-3

53175 Bonn/Germany

+49 228 37756322