Heading towards a green concrete plant thanks to completely cement-free paving blocks

In fall 2023, a BFT team had already visited the Lintel concrete plant in Porta Westfalica to learn more about the new Hess block machine and Pemat mixers (see BFT 12/2023). Now, Lintel’s managing director Thomas Theilmeier has invited us back, this time to Rietberg for a very special construction project: the renovation of Rathausstraße using EcoTerraZero concrete blocks, which are particularly sustainable because they are completely cement-free, both in the face and in the core concrete mix.

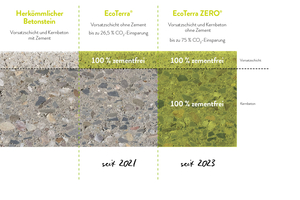

Thanks to the EcoTerraZero manufacturing process developed by Metten Stein & Design, which uses technology that allows all stone formats to be produced with almost any color and surface variation, as with cement-based paver, it is possible to completely eliminate the use of cement. The difference is clear: for example, a 12 cm thick paving stone, as used in the Rietberg project, can save around 16 kg CO2/m2 compared to a cement-based stone, which corresponds to a reduction of approximately 60% compared to a conventional cementitious paving stone. To put this into perspective: if all paving stone production in Germany had been converted to EcoTerraZero by 2023, the amount of CO2 saved would be equivalent to the emissions of a diesel car driving to the moon and back 13,500 times.

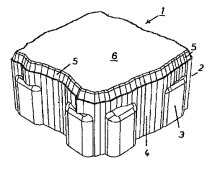

The cement-free concrete block also impresses with a number of improved product properties. Because it does not contain cement, there are no more annoying lime efflorescences, meaning that the colors remain more intense for longer. The block surfaces absorb less dirt and are therefore easier to clean. Another sustainability aspect: depending on customer requirements, recycled material can also be used in the core concrete. Blocks with EcoTerraZero technology are 100% recyclable and can later be returned to the production process for new blocks in a circular process. Of course, this also allows for the production of permeable surface pavements in many different sizes and designs.

Way to the green concrete plant

Thomas Theilmeier comments: “Our understanding of sustainability goes far beyond simply reducing CO2 emissions: short transport routes, the use of recycled materials (RCL), renewable energies, and energy-efficient production processes are firmly anchored in our actions. As currently the only manufacturer in Europe with EPD certification for paving stones, slabs, and traffic management systems, we are continuing on the path to becoming a green concrete plant—and we invite you to join us on this journey.”

The pavers can be used in private areas (gardens and terraces) as well as in public spaces (squares, boulevards, or pedestrian zones). Only gravel, sand, water, and a special mineral compound are used in the production of these climate-friendly stones—no cement. Thanks to the special production technology, up to 75% less CO2 is emitted per square meter for a stone thickness of 8 cm, for example – while offering the same load-bearing capacity and service life and looking identical to conventional concrete stones. EcoTerra technology can be used to produce stones in all conceivable formats up to a size of 100 x 100 cm. Various surface finishes and colors are also possible. The project in Rietberg is currently entering its second construction phase and is expected to be finally completed in 2027. The result will be the new thoroughfare for the nationally renowned and avowed climate city of Rietberg.

CONTACT

Betonwerk Lintel GmbH & Co. KG

Kapellenstraße 1

33378 Rheda-Wiedenbrück/Germany

+49 5242 9283-0