Germany‘s first modular bridge made of prestressed carbon-reinforced concrete is situated in Oldenburg

Henceforth, Germany‘s first CPC modular bridge of the Optima type is situated in Oldenburg (Lower Saxony). For the new pedestrian and cycle path crossing, the city relies on a modern construction system using carbon-reinforced concrete, where the load-bearing structure does not need any steel at all. In the context of the building materials transition, this bridge technology essentially contributes to a resource-efficient renewal of German infrastructure.

The CPC technology (carbon prestressed concrete or prestressed carbon-reinforced concrete) is exemplary of the building materials transition – that is to say a resource-efficient and low-carbon construction with concrete. The pilot project is a 9.60 meter-long, 2.74 meter-wide, weighing about seven tons and only seven centimeter-thick pedestrian and cycle bridge, which will lead over the railway embankment ditch in future. The bridge illustrates how refurbishment of the infrastructure in Germany can be managed already today in a faster manner, using significantly less resources, while reducing carbon emissions.

„Innovative and sustainable solutions such as CPC are decisive for a more sustainable and resource-efficient future of the construction industry,“ states Thorsten Hahn, CEO at Holcim Deutschland. „They are assigned a key role to design the needed rapid refurbishment of infrastructure in Germany in a climate-friendly way. The project of the City of Oldenburg and Holcim Deutschland impressively shows how the public sector and the construction industry are taking this path together.“

The new concrete construction system: slender, climate-friendly and highly load bearing

City head of planning, Christine-Petra Schacht, shows great interest in this project: „We are pleased that this special bridge is situated in our city of Oldenburg. The lighter design perfectly fits in the ecological and sustainable goals set by the City of Oldenburg with the Climate Protection Concept 2035. Thanks to the significantly lower use of materials, we are gradually continuing on this path,“ she states.

The new CPC Optima modular bridge replaces a dilapidated and technically outdated wooden-beam and steel structure from the 1990s. With the new bridge, the City of Oldenburg consequently decided in favor of resource-conserving construction. Because its overall features make CPC the material of choice for climate-friendly and efficient construction projects:

Low material input: The CPC slabs that are three to four times thinner than conventional reinforced-concrete slabs enable material savings of up to 80 percent.

Longer useful life: CPC has an extremely high tensile strength, is resistant and corrosion-free – thus, it is predestined for the use in multi-generation bridges with a service life of up to 100 years.

Low carbon footprint: Since CPC slabs are reusable and are fully recyclable, as building material, they exhibit a significantly reduced carbon footprint of up to 75 percent in comparison to conventional reinforced-concrete slabs.

Reduced weight: CPC allows for weight optimized building structures. The new pedestrian and cycle bridge in Oldenburg-Drielake just weighs 260 kilograms per square meter – and nevertheless is highly load-bearing.

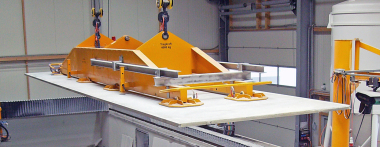

And as the bridge was manufactured in the precast concrete plant in the municipality of Essen (Oldenburg), which is only about 60 kilometers away, the project period was also considerably shortened: By means of a CNC-controlled machine, a CPC element of about 60 m² was cut into precisely fitting units which were pre-assembled at the factory. In this way, it took only six weeks between production and installation in Oldenburg.

About the CPC technology

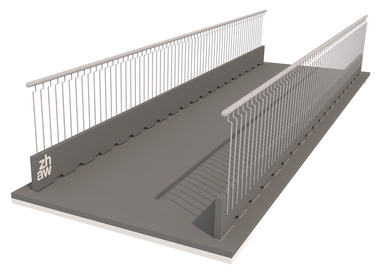

CPC concrete slabs are based on the „Carbon Prestressed Concrete“ technology that is the outcome of a long-term research project conducted at the Zurich University of Applied Sciences in Winterthur (ZHAW). Contrary to conventional concrete slabs with steel reinforcement, CPC slabs are reinforced with thin, prestressed carbon strands. As carbon is lightweight, very resistant to tensile forces and free of corrosion, it is possible to product load-bearing, thin concrete slabs with a thickness of 40 or 70 mm. The OPTIMA modular bridge system is a trough bridge consisting of one carriageway slab and two lateral ribs. In combination, they provide for strength and stability – and are fully made of CPC elements.

CONTACT

Holcim (Deutschland) GmbH

Troplowitzstraße 5

22529 Hamburg /Germany

+49 40 3 60 02 0