Building with CPC carbon concrete slabs,

an entirely new type of concrete construction –

method, engineering, designing

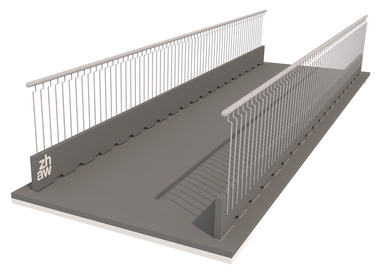

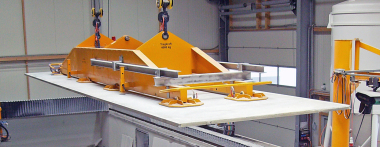

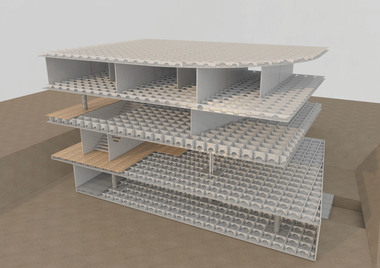

The CPC construction method is based on the semi-finished CPC carbon concrete slab. The CPC slab is produced at the plant in thicknesses ranging from 20 mm to 69 mm and in sizes of up to approx. 4m x 15 m. Using CNC plants or simple machines, the CPC slabs, which have been prestressed with carbon strands in a fine-meshed, multi-layered and endless pattern, can be processed, used on the construction site or assembled into more complex structural elements.

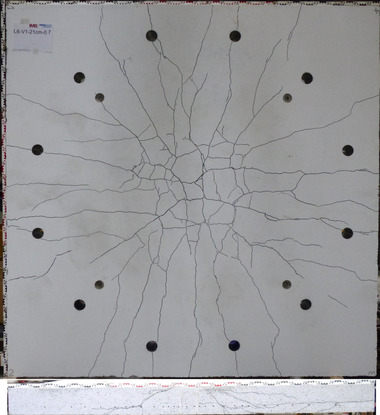

The slabs can be cut to any given size or shape. Within no more than a few centimeters from the cutting edge, the full prestressing force is applied to the slab, enabling it to be subjected to flexural and shear stresses in any given direction.

Since 2012, CPC slabs have been used in Switzerland as balcony slabs, staircases, platforms, as replacement pavements on pedestrian bridges, for elevated slab pavements and many other purposes. Entire structures have also been completed using CPC slabs, such as pedestrian bridges or bicycle shelters. Around 170 projects have been realized to date.

A general technical approval will shortly be granted by the German Institute for Structural Engineering (DIBt), permitting the use of CPC slabs in Germany as slabs exposed to flexural and shear loading.

CPC construction is exceptionally resource-efficient, saving between 50 % and 80 % in resources and weight compared to conventional concrete construction methods. In addition, the tremendous reduction in weight has a positive influence on the overall structure, in particular when carrying out reconstruction measures.

Research has already begun regarding the use of CPC slabs in tunnel construction, road bridge construction and for the entire supporting structure in building construction. Initial investigations show that, in terms of sustainability, a quantum leap has been achieved with this new construction method. Cost analyses show that, even with current prices of material, CPC construction will not be more expensive in the future than conventional reinforced-concrete construction. CPC construction does not sacrifice individuality in comparison with poured-in-place construction.