From a tinkerer to a leading manufacturer of prestressed concrete technology

The success story of Paul Maschinenfabrik began in 1925, when Max Paul set up a mechanical workshop in his father‘s facility in the German town of Dürmentingen. For a start, he manufactured special machinery for the production of whips there.

During the first years, Max Paul kept his head above water with diverse activities – from operating a community laundry to a straw rope and seaweed spinning mill through to the repair of sewing machines and bicycles. In 1935, he applied a patent for the production of aircraft parts which was used in England. The production of machines for manufacturing whips began as of 1936. Thanks to his inventiveness and technical know-how, the business situation had already improved in the years before the war.

Expansion

After the Second World War, the sons Berthold and Odilo Paul joined the company. In 1946, they developed together the first double-edging circular saw which became a big success. In the 1950s, Paul expanded its sales program by additional wood processing machines and got started into the prestressed concrete technology in 1953. The first single-wire stressing jack with the then revolutionary two-button operation followed in 1959.

Until 1965, the company grew to a workforce of 120 people and a production area of 4,500 m². Important innovations of that time were the Tensa SM prestressing technology (1960), the first undercut cross-cut saw (1966), the Tensa M multi-wire stressing jack (1970) and the heavy-duty double-edging circular saw S1200 (1970). In the mid-1970s, part of the production was relocated to Riedlingen; Paul employed 180 people in total on an area of 11,500 m².

Introduction of computer technology

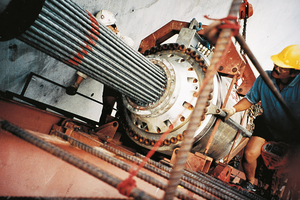

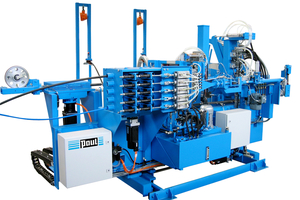

The 1980s were characterized by automation. Paul developed the first CNC cross-cut systems (1982), the automated edging system AB920 (1983) and the first automated button-heading machine for railroad sleepers (1989). The prestressed concrete department supplemented its portfolio by multi-wire stressing jacks for cable-stayed bridges (1982). In 1985, the workforce had already grown to 210 people on a production area of 17,500 m².

In the 1990s, Paul set benchmarks with innovations like the first prestressing robot for railroad sleepers and the modular circular multi-rip saw K34M. In 1995, the company had 245 employees on 21,000 m² and, moreover, developed a multi-wire stressing jack for driven piles. In 1997, Paul was substantially involved in the reconstruction of the Frauenkirche church in Dresden – using specifically developed prestressing technology. As the capacities were exhausted at the main factory in Dürmentingen, Paul started the construction of a new factory in the town‘s industrial zone in 1999.

Turn of the millennium

The new factory was completed right to the 75-year company anniversary in 2000. At the same time, the prestressed concrete department developed the Tensa Control measuring and recording system. Now, both factories employed around 270 people, the production area had extended to 30,000 m². In 2002, Paul Maschinenfabrik was awarded with the business medal of the German State of Baden-Wuerttemberg. Besides, Paul brought the next control generation Maxi 5 to the market.

In 2009, the company introduced its first Wood Scanning system for the wood processing industry. Originally conceived as a cost-effective product, it has been developing step by step to an AI-supported scanner. In 2010, the factory in Dürmentingen was expanded once again, with reaching an area of 37,000 m². In 2012, the entry into strand lifting technology took place including a comprehensive product portfolio for lifting, lowering and displacement of heavy loads.

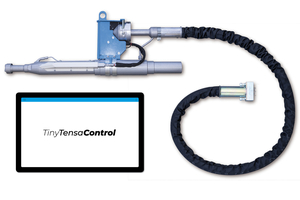

In 2014, Paul took over the long-standing competitor, Reinhardt Maschinenbau located in Rottweil-Neukirch, with maintaining the Reinhardt brand since then. In 2016, the in-house developed, fully-automated storage system for bar material was commissioned in Riedlingen, and the largest multi-wire stressing jack with stressing force of 22,000 kN was delivered to the customer. In 2017, Paul developed a method for an automated inspection of button heads, which was submitted for the Innovation Prize of the Supplier Industry for Concrete Components. Automation clearly gathered speed in industrial wood processing due to robotic solutions and the Rip Scanning system. In 2019, with the Tiny Tensa Control, a recording system based on a tablet was launched for the production of prestressed precast concrete elements.

Looking to the future with confidence

In 2020, Paul invested in the largest machining center in the company history – an ultra-modern plant, allowing the processing of very large machine frames and components flexibly and precisely in just one clamping. Since 2021, Paul Maschinenfabrik has been managed in the third and fourth generation by Barbara Hering, Alexander und Maximilian Paul. Hence, the company will still remain a family-run enterprise in the future.

In 2023, artificial intelligence found its way into Paul products. The latest generation of machines impresses with intelligent image processing, scanners capable of learning and self-propelled transport systems. AI will continue to play a key role in product development in future. In 2024 was the start of construction of a new production hall in Dürmentingen, with the aim to bring the Riedlingen and Dürmentingen factories together in the long run.

In 2025, Paul is celebrating its 100-year anniversary in the new production hall in Dürmentingen. What began as a mechanical workshop in 1925 has long since developed to an internationally active company in the three business segments: circular sawing technology, prestressed concrete technology and strand lifting technology.

CONTACT:

Paul Maschinenfabrik GmbH & Co. KG

Max-Paul-Str. 1

88525 Dürmentingen/Germany

+ 49 7371 500-0