Flood protection: Mega dam with view of

the Zugspitze

In the district of Garmisch-Partenkirchen, a dam was created for a federal highway through a natural depression. The project was already presented in our 2025 yearbook. The new volume „Beton Bauteile 2026“ (Concrete Components 2026) has now been published and can be ordered from the Bauverlag shop.

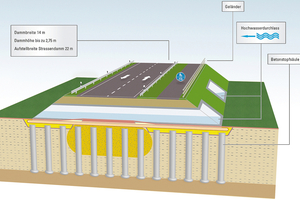

The dam is characterized by numerous flow channels that prevent the Loisach river from damming up, thus minimizing flood damage. The Murnauer Moos is located in the district of Garmisch-Partenkirchen on the northern edge of the Bavarian Alps. With an area of 32 km², it is considered the largest contiguous, near-natural moorland area in Central Europe. It is crossed by State Road 2062, which connects Federal Highway 2 in the market town of Murnau am Staffelsee with Federal Highway 11 in the municipality of Kochel am See. Because the entire road within the moor is completely flooded even during minor, sometimes annual, flooding events, resulting in regular road closures, this section was raised by approximately 2.75 m through the construction of a dam. Twenty rectangular culverts with a total length of 460 m from the Hans Rinninger u. Sohn GmbH u. Co. KG concrete plant in Kißlegg in the Allgäu region ensure a regulated flow of water from southwest to northeast through the dam.

The St 2062 state road is one of the two main access roads to the accident hospital in Murnau, and when it was closed, a long detour always had to be taken. The road was also seen as a barrier and thus a major burden on the water balance: until now, water could only flow from southwest to northeast along the natural drainage system through the few existing culverts under the road. The plan was therefore to raise the road by 2.75 m with a cross-section of 7 m and a 1.50 m wide shoulder along the northeast edge of the roadway; also with a spacing of 2 m, a bituminous cycle path 2.50 m wide with a 0.50 m wide shoulder. Dipl.-Ing. Wolfgang Rieger from the Weilheim State Building Authority describes the measure: „We first had to excavate around 7,000 m³ of peat to create a stable working surface for the construction equipment before construction work on the dam could begin. To stabilize the dam to be raised on the peat subsoil, 2,835 concrete columns with a diameter of 0.6 m and a flared base were first constructed at an average embedment depth of approx. 10 m. This corresponds to around 10,000 m³ of concrete. On top of the completed concrete columns, an approx. 10,000 m² load distribution pad with a thickness of 40 cm was constructed in sections in the form of layers of geogrid and fine gravel.

Changing the hydrological condition of the bog as little as possible

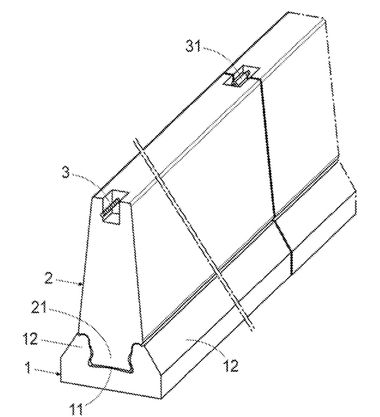

In order to alter the actual hydrological condition of the moor as little as possible, the new road embankment was constructed on the stabilized subsoil with 20 reinforced concrete rectangular culverts from the Hans Rinninger u. Sohn GmbH u. Co. KG concrete plant in Kißlegg. In the event of flooding, the water can thus continue to flow unhindered through the moor. The culverts, each approximately 23 m long and consisting of eight frame profiles and two embankment sections, have a clear width of 2 m and a clear height of 1.60 m with a wall thickness of 20 cm all around, whereby the positioning of the culverts is in alignment with the grid of the concrete plug columns. Robert Hyna from Hyna + Weiß Bauingenieure GmbH in Friedberg explains: „The prefabricated culverts were placed on the 10 cm thick fine gravel subgrade above the load distribution pad. With the concrete plug columns spaced 1.85 m apart, the culverts were brought to alignment with the wall areas directly above the concrete plug columns.“ This means that the culverts are located above two adjacent rows of columns.“ As each frame weighs only approx. 10 t, they could be easily moved by Richard Schulz Tiefbau GmbH & Co. KG using an excavator, without the need for a heavy crane. Following the embankment filling, the roadway and the footpath and cycle path were asphalted.

Precast elements perfectly tailored to requirements

Jörg Rinninger, managing partner of the concrete plant, describes the special features of the project: „Our planning department was involved in the project from the very beginning. This enabled us to design the components down to the smallest detail in such a way that they were perfectly matched to the concrete columns – certainly a major advantage for logistics on the construction site. The components were made of high-performance concrete C 60/75 with very low water penetration and high-quality exposed concrete surfaces.“ Wolfgang Rieger adds: „In fact, the precast solution was also a logistical challenge. After all, 200 components had to be delivered and placed on the narrow dam. Thanks to the excellent support from the manufacturer – even during the planning phase – and perfectly coordinated just-in-time delivery, the assembly went according to plan. Ultimately, the precast construction method was significantly faster than a solution using in-situ concrete.“

Conclusion

On October 27, 2023, the state road was reopened to traffic after a construction period of just over a year. Already during the construction phase, on August 29, 2023, the moor was once again carrying plenty of water and the culverts were already flowing at a height of one meter – a successful test run for the entire system. Wolfgang Rieger concludes: „Thanks to the elevation of the road, it will no longer need to be closed in the future – you can even see the Zugspitze mountain through the reeds from your car now.“

CONTACT

Hans Rinninger u. Sohn

GmbH u. Co. KG

Stolzenseeweg 9

88353 Kißlegg/Germany

+49 7563 932-0