Components instead of Buildings: Modular 3D concrete printing solutions

With modular 3D concrete printing solutions, Umdasch Group enhances proven construction methods exactly where they create the most added value – for more efficiency, design freedom and sustainability in construction.

Partner along the entire life cycle

Umdasch Group describes itself as the future partner along the entire life cycle of a building object - from development to planning, construction, outfitting and ongoing operation, refurbishment through to demolition and recycling. The three main themes at bauma provide an insight into this holistic approach: Renewable Spaces, Future Spaces and Human Spaces. In the “Home for Future Spaces”, the Umdasch Group Ventures innovation hub showcases moders construction methods and technologies that make construction more efficient, sustainable and flexible.

Those who print cleverly, print modularly

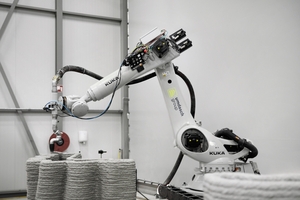

One of the most forward-looking construction method is 3D concrete printing - but with a distincly different approach: Instead of printing entire buildings, Umdasch Group focuses deliberately on the precise production of modular components that are structurally and materially optimized. Rather than replacing traditional construction, 3D concrete printing is intended to strategically complement it – specifically where modular solutions offer distinct advantages: shorter construction times, high dimensional accuracy, reduced material usage and significantly greater flexibility in planning and execution. Especially in combination with established technologies such as efficient formwork, this creates innovative solutions that resonate with both clients and construction companies.

Concrete mixes made from local raw materials

A quality feature for customers: At Umdasch Group, printing is done using real concrete - not mortar. The concrete mixes, composed of locally sourced raw materials and aggregate size of up to 11.2 millimetres, enable the production of robust and durable components. Compared to cement-rich, crack-prone mortar mixtures, this results in lower consumption and reduces CO2 emissions.

“All of this not only ensures significantly greater durability, but also meets established constrution standards - a clear advantage over mortar-based systems,”, explains Martin Ceccon, Chief Growth Officer of Umdasch Group AG.

With “3D Concrete Print Solutions”, the Umdasch Group offers a comprehensive ecosystem – from customized concrete mixes and advanced 3D printing technology to flexible rental and purchase models. These solutions are designed to be tailored to the needs of architects, engineers and construction companies.

CONTACT

Umdasch Group

Josef Umdasch Platz 1

3300 Amstetten/Austria

+43 7472 – 605