3D concrete printing sets new benchmark in precast construction

Progress Group based in Brixen, Italy, has achieved a technological breakthrough with its proprietary SPI-3D (Selective Paste Intrusion) concrete printer. Its ability to produce complex shapes with utmost precision while utilizing resources sustainably makes the process a milestone for the precast industry. The resort Pareus in Caorle, Italy, is the most significant reference to date, demonstrating the technology’s potential on a large industrial scale.

New dimensions of form and function

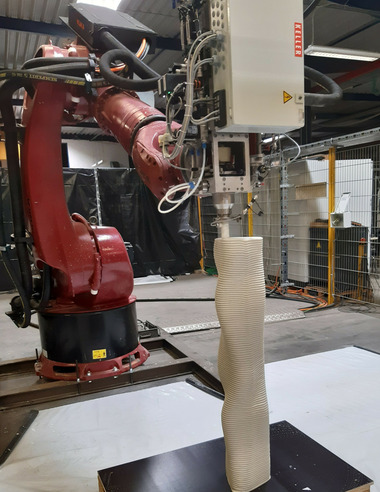

Developed by the Progress research and development team, the SPI 3D concrete printer expands conventional prefabricated element production, providing architects, engineers, and manufacturers with a flexible tool. Thanks to its layer resolution of just three millimeters, it can produce components to the highest degree of detail, including façade panels, furniture, and custom precast elements. The printer is just 5 m long, 2.8 m wide, and 1.5 m high to ensure efficient transport and further processing.

SPI technology: Layer by layer to the top

The selective paste intrusion (SPI) process works similarly to selective laser sintering (SLS). While SLS uses a laser to melt the powder, SPI uses a print head to apply a paste consisting of water and cement to a sand bed with pinpoint precision, which allows the sand mix to harden in predefined areas to create the intended geometry. After placement of each layer, the platform is lowered, and a new layer of sand is added. This loose sand acts as a support structure throughout the entire process. Once printing is complete, the material hardens within 24 hours, after which excess sand is vacuumed off and reused completely.

Symbiosis of aesthetics and functionality

The SPI technology developed by Progress Group revolutionizes façade design. This system combines the benefits of 3D printing with the proven features of double-wall systems. The outer layer is fabricated using the 3D printing process, providing a high degree of architectural design freedom and a unique appearance. The subsequent layer is formed by standardized double walls to ensure stability, thermal insulation, and soundproofing. The resulting symbiosis of design freedom and functional quality sets the standard for modern construction projects.

Sustainability as a core principle

The process applies material only where it is actually needed. Post-completion, the support structure formed by the sand bed can be fully reused, which reduces material consumption, carbon emissions, and waste generation significantly. Compared to conventional processes, this method brings both economic and environmental benefits without imposing any restrictions on design or functionality.

Resort Pareus in Caorle: Lighthouse project for the industry

The resort Pareus in Caorle, Italy, is the most significant reference for industrial 3D concrete printing to date. Twenty-eight holiday homes are being built on a 28,000 m² site, with a major portion of their load-bearing structures and envelopes primarily constructed using the innovative SPI technology. The scope of the order includes 11,000 m² of façade elements, including 4,000 m² 3D Green Code Thermowand Plus panels, 4,300 m² of double walls, 4,000 m² of Green Code Eco Slabs , and 1,500 m² of Progress XM floor slabs. Pareus is thus proving to be a project of exceptional technical relevance. It demonstrates for the first time that additive manufacturing can be used as a primary production method in the precast industry, rather than just complementing conventional processes. The Green Code Thermowand Plus panel in particular underscores the focus on sustainable solutions.

Timeline and economic significance

Shell construction is scheduled for completion in summer 2026, while the entire resort is set to open in May 2027. Besides providing architectural freedom and ensuring a high quality standard, the project also demonstrates economic efficiency. Production in a controlled factory environment speeds up processes, reduces costs, and allows for maximum precision to optimize resource utilization and ensure timely project execution.

Benchmark for international markets

The Pareus resort sets a benchmark for future large-scale precast construction projects. Its size and technical complexity take 3D concrete printing past the pilot phase and establish it as a market-ready method. The combination of cost effectiveness, sustainability, and design freedom sets new standards, making Progress Group’s SPI 3D concrete printing a strategic tool for the global precast industry.

CONTACT

Progress Group

3D Concrete Printing

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979 100